Irobhothi lohlobo lwe-BRTIRWD1506A iyirobhothi enama-eksisi ayisithupha elakhiwe yi-BORUNTE ukuze kuthuthukiswe imboni yokufaka izicelo zokushisela. Irobhothi linesakhiwo esihlangene, ivolumu encane nesisindo esincane. Umthwalo omkhulu ngu-6kg, ubude bengalo obukhulu ngu-1600mm. Isihlakala sisebenzisa isakhiwo esingenalutho esinokulandelela okulula kanye nesenzo esivumelana nezimo. Ibanga lokuvikela lifinyelela ku-IP54. Ingangeni uthuli futhi ingangeni emanzini. Ukunemba kokuma okuphindayo ngu-±0.05mm.

Ukuma Okunembile

Ngokushesha

Impilo Emide Yenkonzo

Izinga Lokuhluleka Okuphansi

Yehlisa Umsebenzi

Ezokuxhumana

| Into | Ibanga | Isivinini esikhulu | ||

| Ingalo | J1 | ±165° | 163°/s | |

| J2 | -100°/+70° | 149°/s | ||

| J3 | ±80° | 223°/s | ||

| Isihlakala | J4 | ±150° | 169°/s | |

| J5 | ±110° | 270°/s | ||

| J6 | ±360° | 398°/s | ||

|

| ||||

| Ubude Bengalo (mm) | Ikhono Lokulayisha (kg) | Ukunemba Kokuma Okuphindaphindiwe (mm) | Umthombo wamandla (kVA) | Isisindo (kg) |

| 1600 | 6 | ±0.05 | 4.64 | 166 |

Izici ezibalulekile zokusebenzisa irobhothi lokushisela:

1. Zinzisa futhi uthuthukise izinga lokushisela ukuze uqinisekise ukufana kwayo.

Ukusebenzisa i-Robot welding, imingcele ye-welding ye-weld ngayinye ihlala njalo, futhi ikhwalithi ye-weld ayithinteki kakhulu izici zomuntu, inciphisa izidingo zamakhono okusebenza kwabasebenzi, ngakho ikhwalithi yokushisela izinzile.

2. Thuthukisa umkhiqizo.

Irobhothi lingakhiqizwa ngokuqhubekayo amahora angama-24 ngosuku. Ngaphezu kwalokho, ngokusetshenziswa kobuchwepheshe bokushisela obushesha kakhulu futhi obusebenzayo, ukusebenza kahle kweRobot welding welding kuthuthukiswa kakhulu.

3. Sula umjikelezo womkhiqizo, kulula ukulawula ukuphuma komkhiqizo.

Isigqi sokukhiqiza samarobhothi silungisiwe, ngakho-ke uhlelo lokukhiqiza lucace kakhulu.

4.Fushanisa umjikelezo wokuguqulwa komkhiqizo

Ingakwazi ukufeza i-welding automation yemikhiqizo ye-batch encane. Umehluko omkhulu phakathi kwerobhothi nomshini okhethekile ukuthi lingakwazi ukuzivumelanisa nokukhiqizwa kwezingxenye zokusebenza ezihlukene ngokulungisa uhlelo.

-

Spot welding

-

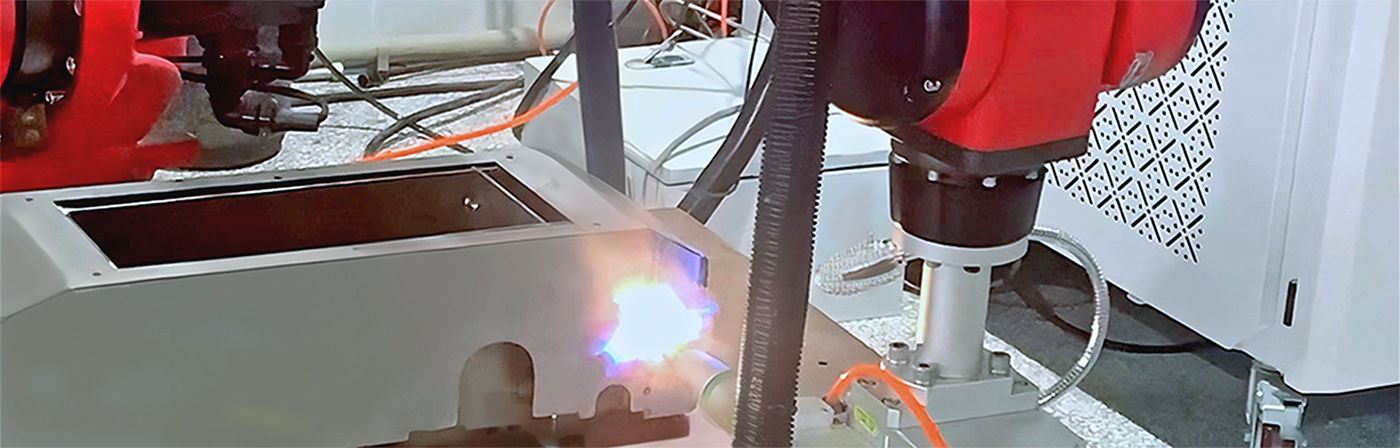

I-laser welding

-

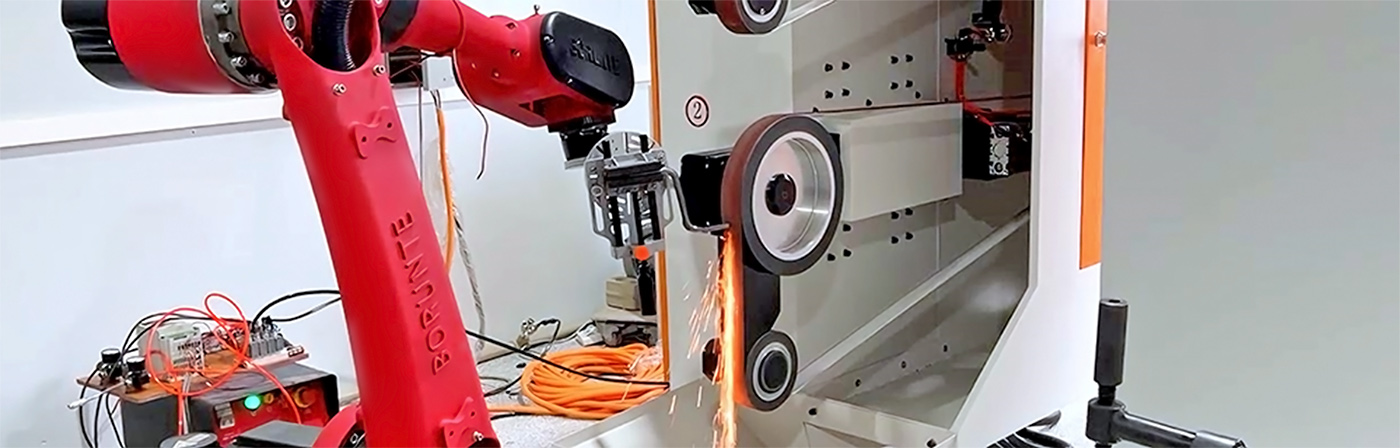

Ukupholisha

-

Ukusika

Izigaba zemikhiqizo

I-BORUNTE kanye nezihlanganisi ze-BORUNTE

Ku-ecosystem ye-BORUNTE, i-BORUNTE inesibopho se-R&D, ukukhiqizwa, nokuthengiswa kwamarobhothi nama-manipulators. Abahlanganisi be-BORUNTE basebenzisa izinzuzo zabo zemboni noma zensimu ukuze banikeze idizayini yesicelo esibulalayo, ukuhlanganiswa, kanye nesevisi yangemva kokuthengisa yemikhiqizo ye-BORUNTE abayithengisayo. Abahlanganisi be-BORUNTE nabakwa-BORUNTE bafeza izibopho zabo ezihlukene futhi bazimele komunye nomunye, basebenza ndawonye ukukhuthaza ikusasa eliqhakazile le-BORUNTE.

-

-

-

-

Phezulu