Irobhothi lohlobo lwe-BRTIRWD1606A iyirobhothi enama-eksisi ayisithupha elakhiwe yi-BORUNTE embonini yokufaka izicelo zokushisela. Irobhothi lihlangene ngokuma, lincane ngosayizi futhi lilula ngesisindo. Umthwalo wayo omkhulu ngu-6kg kanti izingalo zayo zifinyelela ku-1600mm. Isakhiwo esingenalutho sesihlakala, umugqa okahle kakhudlwana, isenzo esivumelana nezimo. Eyokuqala, eyesibili neyesithathu ifakwe izinciphisi ezinembayo, kanti eyesine, eyesihlanu neyesithupha ifakwe izakhiwo zegiya ezinembayo, ngakho isivinini esihlangene esinesivinini esikhulu singakwazi ukwenza imisebenzi eguquguqukayo. Ibanga lokuvikela lifinyelela ku-IP54. Ingangeni uthuli futhi ingangeni emanzini. Ukunemba kokuma okuphindayo ngu-±0.05mm.

Ukuma Okunembile

Ngokushesha

Impilo Emide Yenkonzo

Izinga Lokuhluleka Okuphansi

Yehlisa Umsebenzi

Ezokuxhumana

| Into | Ibanga | Isivinini esikhulu | ||

| Ingalo | J1 | ±165° | 158°/s | |

| J2 | -95°/+70° | 143°/s | ||

| J3 | ±80° | 228°/s | ||

| Isihlakala | J4 | ±155° | 342°/s | |

| J5 | -130°/+120° | 300°/s | ||

| J6 | ±360° | 504°/s | ||

|

| ||||

| Ubude Bengalo (mm) | Ikhono Lokulayisha (kg) | Ukunemba Kokuma Okuphindaphindiwe (mm) | Umthombo wamandla (kVA) | Isisindo (kg) |

| 1600 | 6 | ±0.05 | 6.11 | 157 |

Ungakhetha kanjani amarobhothi we-welding welding?

1. Thola inqubo yokushisela: Nquma inqubo yokushisela oyoyisebenzisa, njenge-MIG, TIG, noma i-spot welding. Izinqubo ezihlukene zingadinga izinhlobo ezahlukene zokulungisa.

2. Qonda ukucaciswa kocezu lomsebenzi: Hlaziya ubukhulu, ukwakheka, kanye nempahla yesiqephu somsebenzi esidinga ukushiselwa. I-fixture kufanele ibambe futhi ibambe ngokuphephile ucezu lomsebenzi ngesikhathi sokushisela.

3. Cabangela izinhlobo zamalunga okushisela: Thola izinhlobo zamalunga (isb., ijoyinti lezinqe, ilunga lethanga, ilunga lekhona) ozobe ushisela, njengoba lokhu kuzoba nomthelela ekwakhiweni nasekumisweni kwesakhiwo.

4. Hlola ivolumu yokukhiqiza: Cabangela umthamo wokukhiqiza kanye nemvamisa okuzosetshenziswa ngayo. Ngokukhiqizwa kwevolumu ephezulu, ukuqina okuqinile nokuzenzakalelayo kungase kudingeke.

5. Hlola izidingo zokunemba kwe-welding: Thola izinga lokunemba elidingekayo kuphrojekthi yokushisela. Ezinye izinhlelo zokusebenza zingadinga ukubekezelelana okuqinile, okuzoba nomthelela ekwakhiweni kwesakhiwo nokwakhiwa.

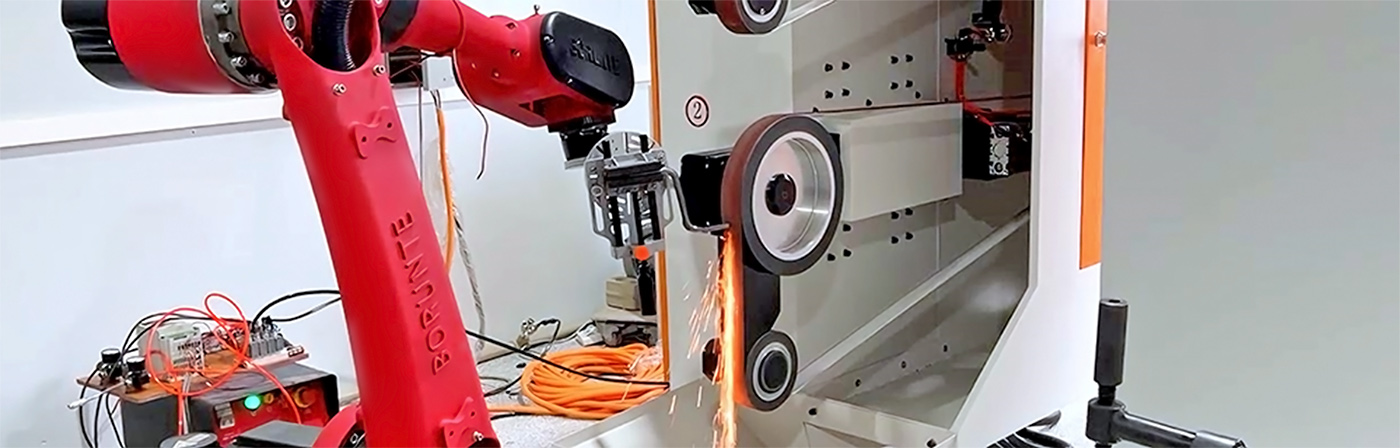

Isakhiwo esijwayelekile se-BRTIRWD1606A

I-BRTIRWD1606A yamukela isakhiwo samarobhothi ahlangene eeksisi ayisithupha, ama-servo motors ayisithupha ashayela ukuzungezisa kwezimbazo ezihlangene eziyisithupha ngokusebenzisa izinciphisi namagiya. Inamadigri ayisithupha enkululeko, okungukuthi ukuzungezisa (X), ingalo engezansi (Y), ingalo engenhla (Z), ukuzungezisa isihlakala (U), ukushwiba isihlakala (V), nokuzungezisa isihlakala (W).

I-BRTIRWD1606A ijoyinti lomzimba lenziwe nge-aluminium eyinsimbi noma insimbi ecijile, iqinisekisa amandla aphezulu, isivinini, ukunemba, nokuzinza kwerobhothi.

-

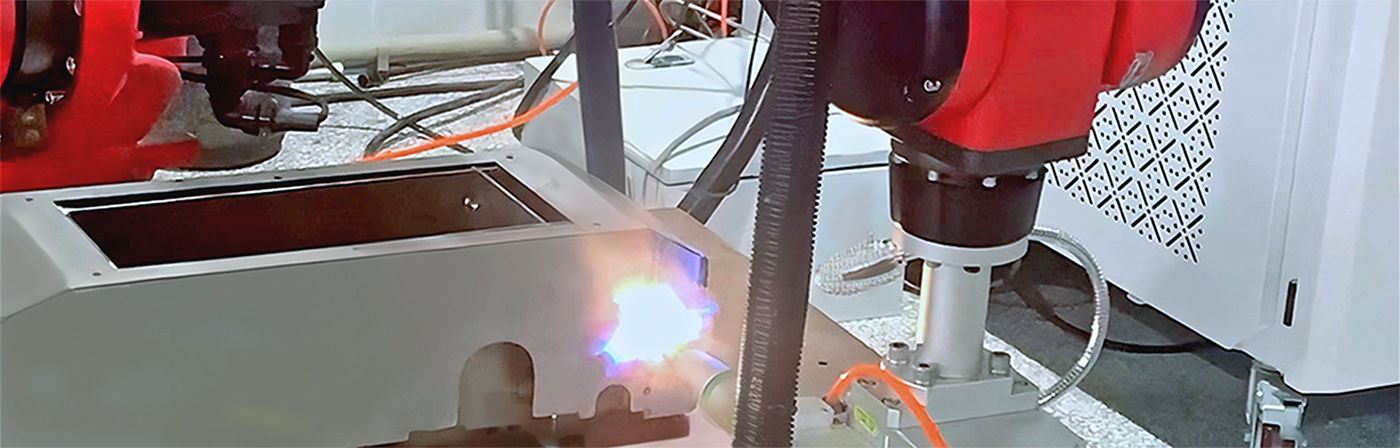

Spot welding

-

I-laser welding

-

Ukupholisha

-

Ukusika

Izigaba zemikhiqizo

I-BORUNTE kanye nezihlanganisi ze-BORUNTE

Ku-ecosystem ye-BORUNTE, i-BORUNTE inesibopho se-R&D, ukukhiqizwa, nokuthengiswa kwamarobhothi nama-manipulators. Abahlanganisi be-BORUNTE basebenzisa izinzuzo zabo zemboni noma zensimu ukuze banikeze idizayini yesicelo esibulalayo, ukuhlanganiswa, kanye nesevisi yangemva kokuthengisa yemikhiqizo ye-BORUNTE abayithengisayo. Abahlanganisi be-BORUNTE nabakwa-BORUNTE bafeza izibopho zabo ezihlukene futhi bazimele komunye nomunye, basebenza ndawonye ukukhuthaza ikusasa eliqhakazile le-BORUNTE.

-

-

-

-

Phezulu