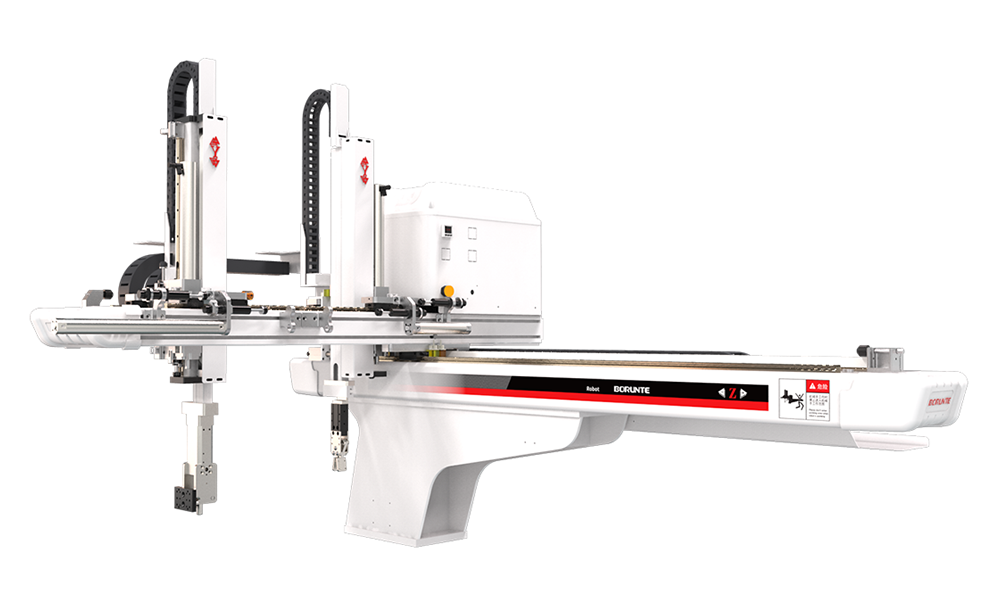

I-BRTB06WDS1P0/F0 ingalo yerobhothi enqamulayo isebenza kuzo zonke izinhlobo zomshini womjovo ovundlile ongu-30T-120T wemikhiqizo yokukhipha kanye ne-sprue. Ingalo eqondile iwuhlobo lwe-telescopic, enengalo yomkhiqizo kanye nengalo yomgijimi, kukhishwe amapuleti amabili noma imikhiqizo yesikhunta samapuleti amathathu. I-axis enqamulayo ishayelwa yi-AC servo motor. Ukuma okunembile, isivinini esisheshayo, impilo ende, nezinga lokuhluleka eliphansi. Ukufaka i-manipulator, ukukhiqiza kuzokwenyuka ngo-10-30% futhi kuzonciphisa izinga elingalungile lemikhiqizo, kuqinisekiswe ukuphepha kwabaqhubi, kunciphise abasebenzi futhi kulawule ngokunembile okukhiphayo ukuze kuncishiswe imfucuza.

Ukuma Okunembile

Ngokushesha

Impilo Emide Yenkonzo

Izinga Lokuhluleka Okuphansi

Yehlisa Umsebenzi

Ezokuxhumana

| Umthombo wamandla (KVA) | I-IMM enconyiwe (ithani) | I-Traverse Driven | Imodeli ye-EOAT |

| 1.69 | 30T-120T | I-AC Servo motor | eyodwa yokuncela eyodwa |

| I-Traverse Stroke (mm) | I-Crosswise Stroke (mm) | I-Stroke Emile (mm) | I-Max.loading (kg) |

| 1100 | P:200-R:125 | 600 | 3 |

| Isikhathi Sokukhipha Isikhathi Esomile (isekhondi) | Isikhathi Somjikelezo Wokoma (isekhondi) | Ukusetshenziswa Komoya (NI/umjikelezo) | Isisindo (kg) |

| 1.6 | 5.8 | 3.5 | 175 |

Ukumelwa kwemodeli: W: Uhlobo lwe-Telescopic. D: Ingalo yomkhiqizo +ingalo yomgijimi. I-S5: I-axis emihlanu eshayelwa yi-AC Servo Motor( Traverse-axis, Vertical-axis + Crosswise-axis).

Isikhathi somjikelezo esishiwo ngenhla siyimiphumela yezinga lokuhlola langaphakathi lenkampani yethu. Enqubweni yangempela yokusetshenziswa komshini, zizohluka ngokuya ngokusebenza kwangempela.

| A | B | C | D | E | F | G | H |

| 1200 | 1900 | 600 | 403 | 1100 | 355 | 165 | 210 |

| I | J | K | L | M | N | O | |

| 110 | 475 | 365 | 1000 | 242 | 365 | 933 |

Asikho esinye isaziso uma ukucaciswa nokubukeka kushintshiwe ngenxa yentuthuko nezinye izizathu. Siyabonga ngokuqonda kwakho.

Ungashintshela kanjani kumodi yezandla futhi uyisebenzise?

Faka isikrini semanuwali, ungenza ukusebenza okwenziwa ngesandla, usebenzise i-manipulator ukuze usebenzise isenzo ngasinye, futhi ulungise ingxenye ngayinye yomshini (uma usebenza ngesandla, qinisekisa ukuthi kukhona isignali yokuvula isikhunta ngaphambi kokuqhubeka, futhi uqinisekise ukuthi isikhunta akathintwa). Ukuze uqinisekise ukuphepha kwama-manipulators kanye nokubunjwa komshini wokubumba umjovo, kunemikhawulo elandelayo:

Ngemuva kokuthi irobhothi lehlile, alikwazi ukunyakaza okuqondile noma okuvundlile.

Ngemva kokuba irobhothi lehlile, alikwazi ukunyakaza elivundlile. (Ngaphandle kwendawo yokuphepha ngaphakathi kwemodeli) .

Uma ingekho isignali yokuvula isikhunta, i-manipulator ayikwazi ukwenza ukunyakaza okuya phansi ekubunjeni.

Ukugcinwa kokuphepha (Qaphela):

Ngaphambi kokulungisa i-manipulator, izisebenzi ezilungisayo sicela ufunde le mininingwane yokuphepha elandelayo ukuze ugweme ingozi.

1.Sicela uvale amandla ngaphambi kokuhlola umshini womjovo.

2.Ngaphambi kokulungiswa nokugcinwa, sicela uvale ukunikezwa kwamandla kanye nokucindezela okusele komshini womjovo kanye ne-manipulator.

I-3.Ngaphezu komshini oseduze, ukumunca okungalungile, ukuhluleka kwe-valve ye-solenoid kungalungiswa ngokwabo, abanye kufanele kube izisebenzi eziqeqeshelwe ukulungisa, ngaphandle kwalokho zingashintshi ngaphandle kokugunyazwa.

4.Sicela ungashintshi noma ushintshe izingxenye zangempela.

5.Ngesikhathi sokulungiswa kwesikhunta noma ukuguqulwa, sicela unake ukuphepha ukuze ugweme ukulinyazwa umshini wokukhohlisa.

6.Ngemva kokulungisa noma ukulungisa i-manipulator, sicela ushiye indawo yokusebenza eyingozi ngaphambi kokuthuma.

7.Ungawavuli amandla noma uxhume i-compressor yomoya esandleni esiwumshini.

-

Ukubumba umjovo

Izigaba zemikhiqizo

I-BORUNTE kanye nezihlanganisi ze-BORUNTE

Ku-ecosystem ye-BORUNTE, i-BORUNTE inesibopho se-R&D, ukukhiqizwa, nokuthengiswa kwamarobhothi nama-manipulators. Abahlanganisi be-BORUNTE basebenzisa izinzuzo zabo zemboni noma zensimu ukuze banikeze idizayini yesicelo esibulalayo, ukuhlanganiswa, kanye nesevisi yangemva kokuthengisa yemikhiqizo ye-BORUNTE abayithengisayo. Abahlanganisi be-BORUNTE nabakwa-BORUNTE bafeza izibopho zabo ezihlukene futhi bazimele komunye nomunye, basebenza ndawonye ukukhuthaza ikusasa eliqhakazile le-BORUNTE.

-

-

-

-

Phezulu