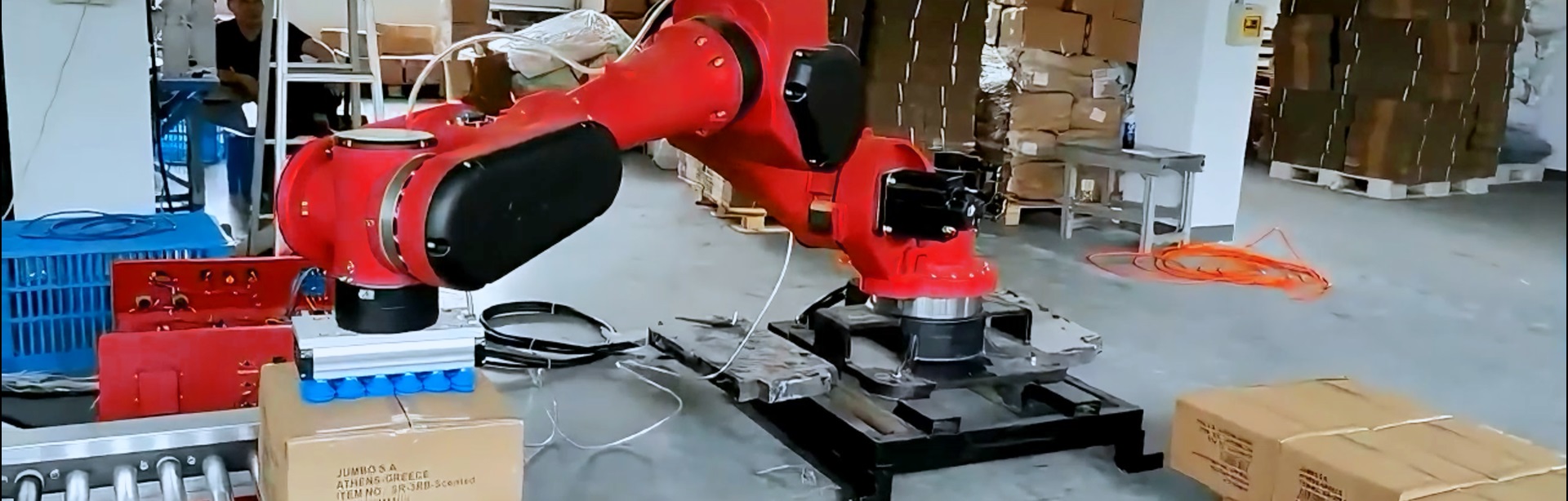

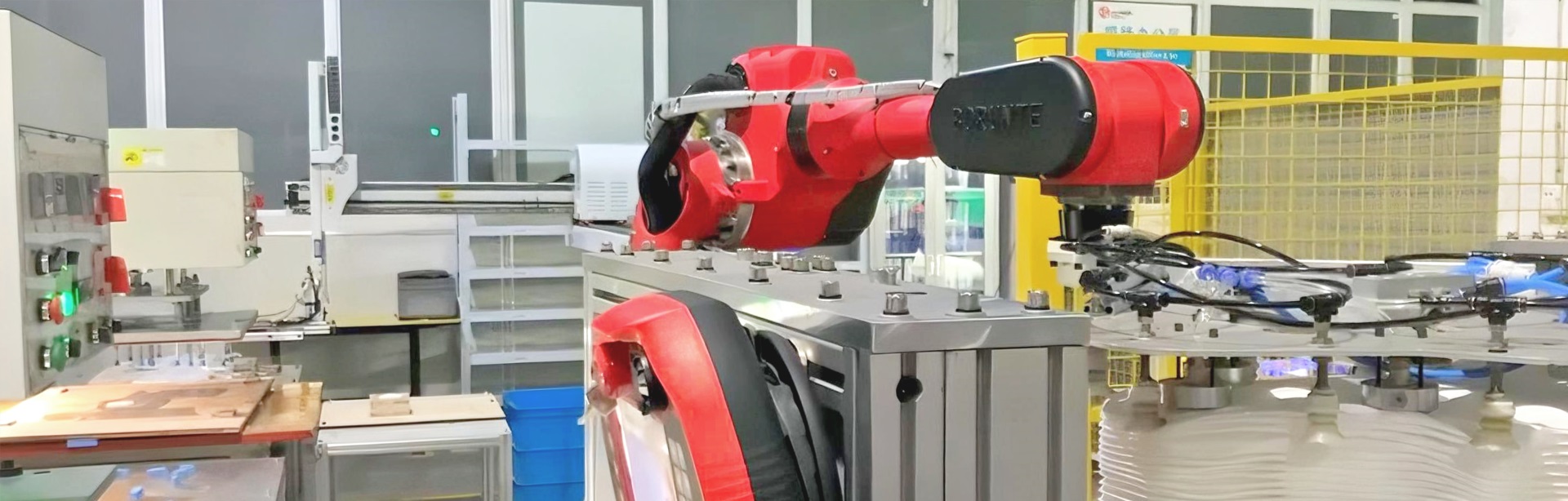

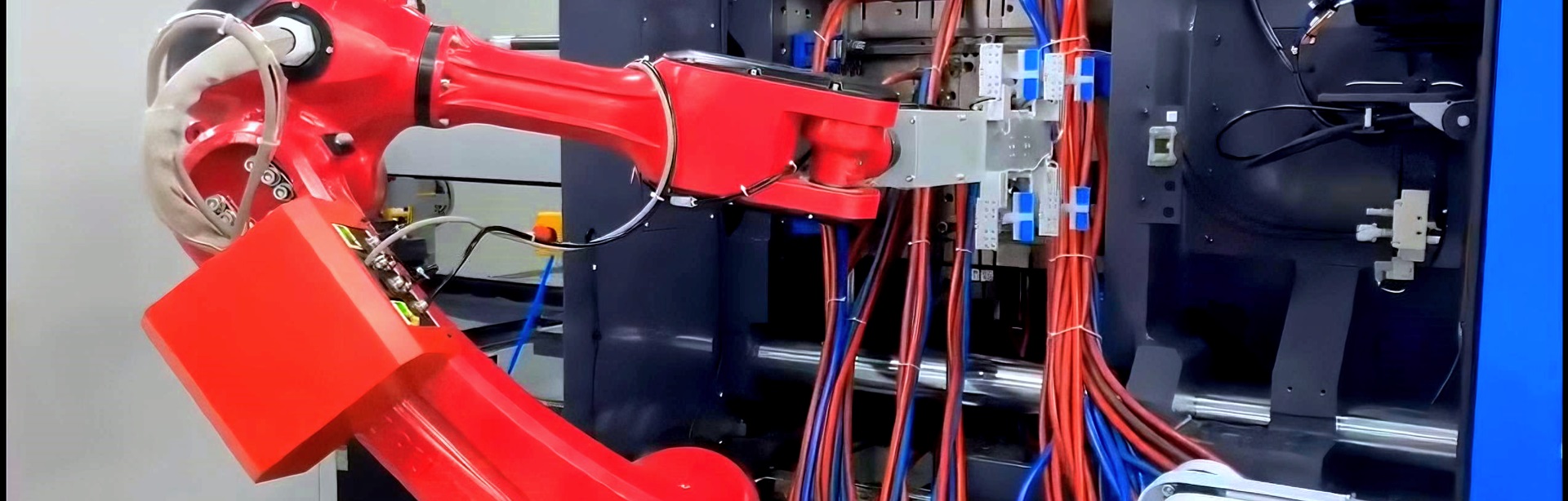

I-BRTIRUS1510A iyirobhothi enama-eksisi ayisithupha athuthukiswe yi-BORUNTE ngezinhlelo zokusebenza eziyinkimbinkimbi ezinamadigri amaningi enkululeko. Umthwalo omkhulu ngu-10kg, ubude bengalo obukhulu ngu-1500mm. Umklamo wengalo yesisindo esilula, isakhiwo esihlangene nesilula semishini, esimweni sokuhamba ngesivinini esikhulu, singenziwa endaweni yokusebenzela encane umsebenzi oguquguqukayo, ukuhlangabezana nezidingo zokukhiqiza okuguquguqukayo. Inamadigri ayisithupha okuguquguquka. Ifanele ukudweba, ukushisela, ukubumba umjovo, ukunyathela, ukukhanga, ukuphatha, ukulayisha, ukuhlanganisa, njll. Yamukela uhlelo lokulawula lwe-HC, olufanele uhla lomshini wokubumba umjovo kusuka ku-200T-600T. Ibanga lokuvikela lifinyelela ku-IP54. Ingangeni uthuli futhi ingangeni emanzini. Ukunemba kokuma okuphindayo ngu-±0.05mm.

Ukuma Okunembile

Ngokushesha

Impilo Emide Yenkonzo

Izinga Lokuhluleka Okuphansi

Yehlisa Umsebenzi

Ezokuxhumana

| Into | Ibanga | Isivinini esikhulu | ||

| Ingalo | J1 | ±165° | 190°/s | |

| J2 | -95°/+70° | 173°/s | ||

| J3 | -85°/+75° | 223°/s | ||

| Isihlakala | J4 | ±180° | 250°/s | |

| J5 | ±115° | 270°/s | ||

| J6 | ±360° | 336°/s | ||

|

| ||||

| Ubude Bengalo (mm) | Ikhono Lokulayisha (kg) | Ukunemba Kokuma Okuphindaphindiwe (mm) | Umthombo wamandla (kVA) | Isisindo (kg) |

| 1500 | 10 | ±0.05 | 5.06 | 150 |

Ukusetshenziswa kwe-BRTIRUS1510A

1. Ukubamba 2. Ukugxiviza 3. Ukubumba umjovo 4. Ukugaya 5. Ukusika 6. Ukuqothula7. I-Gluing 8. Ukupakisha 9. Ukufafaza, njll.

1.Ukuphatha Izinto: Amarobhothi asetshenziswa ukuphatha nokuthutha izinto ezisindayo ezimbonini nasezindaweni zokugcina impahla. Bangakwazi ukuphakamisa, ukupakisha, nokuhambisa izinto ngokunemba, bathuthukise ukusebenza kahle futhi banciphise ubungozi bokulimala emsebenzini.

I-2.I-Welding: Ngokunemba kwayo okuphezulu nokuguquguquka, i-robot ifaneleka kahle izinhlelo zokusebenza zokushisela, ihlinzeka ngama-welds angaguquki futhi anokwethenjelwa.

3.Ukufutha: Amarobhothi ezimboni asetshenziselwa ukudweba izindawo ezinkulu ezimbonini ezifana nezezimoto, i-aerospace, kanye nempahla yabathengi. Ukulawula kwabo okunembile kuqinisekisa ukufana okufanayo kanye nokuqedwa kwekhwalithi ephezulu.

I-4.Ukuhlola: Ukuhlanganiswa kwesistimu yombono werobhothi okuthuthukisiwe kuyenza ikwazi ukuhlola ikhwalithi, iqinisekise ukuthi imikhiqizo ihlangabezana nezindinganiso eziphakeme kakhulu.

I-5.CNC Machining: I-BRTIRUS1510A ingahlanganiswa nemishini ye-Computer Numerical Control (CNC) ukwenza imisebenzi eyinkimbinkimbi yokugaya, ukusika, nokubhoboza ngokunemba okuphezulu nokuphindaphinda.

Ukuhlolwa kokuhlolwa kwerobhothi ngaphambi kokushiya imboni ye-BORUNTE:

I-1.I-Robot iwumshini wokufaka onemba kakhulu, futhi akunakugwemeka ukuthi amaphutha azokwenzeka ngesikhathi sokufakwa.

2.Irobhothi ngalinye kufanele lithole ukunemba kokulinganisa ithuluzi kanye nokulungiswa kwesinxephezelo ngaphambi kokuphuma embonini.

3.Ebangeni lokunemba elinengqondo, ubude be-shaft, i-speed reducer, i-eccentricity kanye neminye imingcele kunxeshezelwa ukuze kuqinisekiswe ukunyakaza kwemishini kanye nokunemba kwethrekhi.

4.Ngemva kokuba isinxephezelo sokulinganiswa singaphakathi kwebanga elifanelekayo (bheka ithebula lokulinganisa ukuze uthole imininingwane), uma ukukhishwa kwesinxephezelo kungenalo ibanga elifanelekayo, kuzobuyiselwa emugqeni wokukhiqiza ukuze kuhlaziywe kabusha, kulungiswe amaphutha futhi kuhlanganiswe, bese emva kwalokho. ilinganiselwe kuze kube ifaneleka.

-

ezokuthutha

-

ukunyathela

-

Ukubumba umjovo

-

IsiPolish

Izigaba zemikhiqizo

I-BORUNTE kanye nezihlanganisi ze-BORUNTE

Ku-ecosystem ye-BORUNTE, i-BORUNTE inesibopho se-R&D, ukukhiqizwa, nokuthengiswa kwamarobhothi nama-manipulators. Abahlanganisi be-BORUNTE basebenzisa izinzuzo zabo zemboni noma zensimu ukuze banikeze idizayini yesicelo esibulalayo, ukuhlanganiswa, kanye nesevisi yangemva kokuthengisa yemikhiqizo ye-BORUNTE abayithengisayo. Abahlanganisi be-BORUNTE nabakwa-BORUNTE bafeza izibopho zabo ezihlukene futhi bazimele komunye nomunye, basebenza ndawonye ukukhuthaza ikusasa eliqhakazile le-BORUNTE.

-

-

-

-

Phezulu