I-BRTIRWD1506A uhlobo lwe-robot yi-robot ye-axis ezintandathu ephuhliswe ngu-BORUNTE kuphuhliso loshishino lwe-welding application. Irobhothi inesakhiwo esincinci, umthamo omncinci kunye nobunzima obulula. Umthwalo ophezulu yi-6kg, ubude bengalo buyi-1600mm. Isihlahla sisebenza kwisakhiwo esinomngxuma kunye nomkhondo olungele ngakumbi kunye nentshukumo ebhetyebhetye. Umgangatho wokukhusela ufikelela kwi-IP54. Ukuthintela uthuli kunye nokungangeni kwamanzi. Ukuphinda ukuchaneka kokumisa yi-±0.05mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±165° | 163°/s | |

| J2 | -100°/+70° | 149°/s | ||

| J3 | ±80° | 223°/s | ||

| Isandla | J4 | ±150° | 169°/s | |

| J5 | ±110° | 270°/s | ||

| J6 | ±360° | 398°/s | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) |

| 1600 | 6 | ±0.05 | 4.64 | 166 |

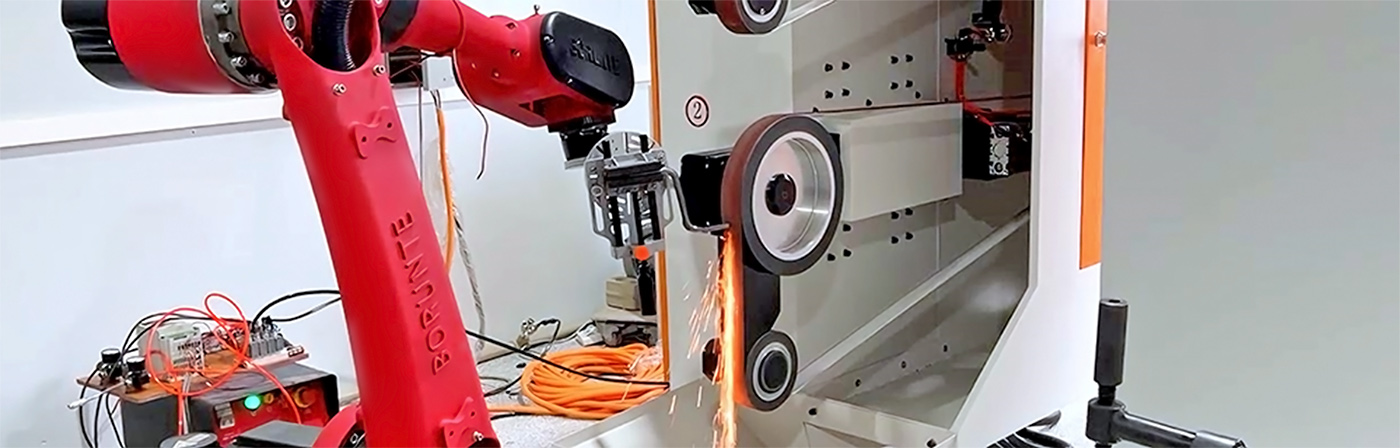

Iimpawu ezibalulekileyo zokusebenzisa irobhothi yokuwelda:

1. Ukuzinzisa kunye nokuphucula umgangatho we-welding ukuqinisekisa ukufana kwayo.

Ukusebenzisa i-Robot welding, i-welding parameters ye-weld nganye ihlala ihleli, kwaye umgangatho we-weld awuchatshazelwa kangako yimiba yabantu, unciphisa iimfuno zezakhono zokusebenza zabasebenzi, ngoko umgangatho we-welding uzinzile.

2. Ukuphucula imveliso.

Irobhothi inokuveliswa ngokuqhubekayo iiyure ezingama-24 ngosuku. Ukongezelela, ngokusetyenziswa kweteknoloji ye-welding ekhawulezayo kunye nokusebenza kakuhle, ukusebenza kakuhle kwe-Robot welding welding kuphuculwe ngakumbi.

3. Sula umjikelo wemveliso, kulula ukulawula imveliso yemveliso.

Isigqi sokuvelisa iirobhothi silungisiwe, ngoko ke isicwangciso sokuvelisa sicacile.

4.Shorten umjikelo wenguqu kwimveliso

Unokufezekisa i-welding automation kwiimveliso ezincinci zebhetshi. Umahluko omkhulu phakathi kwerobhothi kunye nomatshini okhethekileyo kukuba unokuziqhelanisa nokuveliswa kwemisebenzi eyahlukeneyo ngokuguqula inkqubo.

-

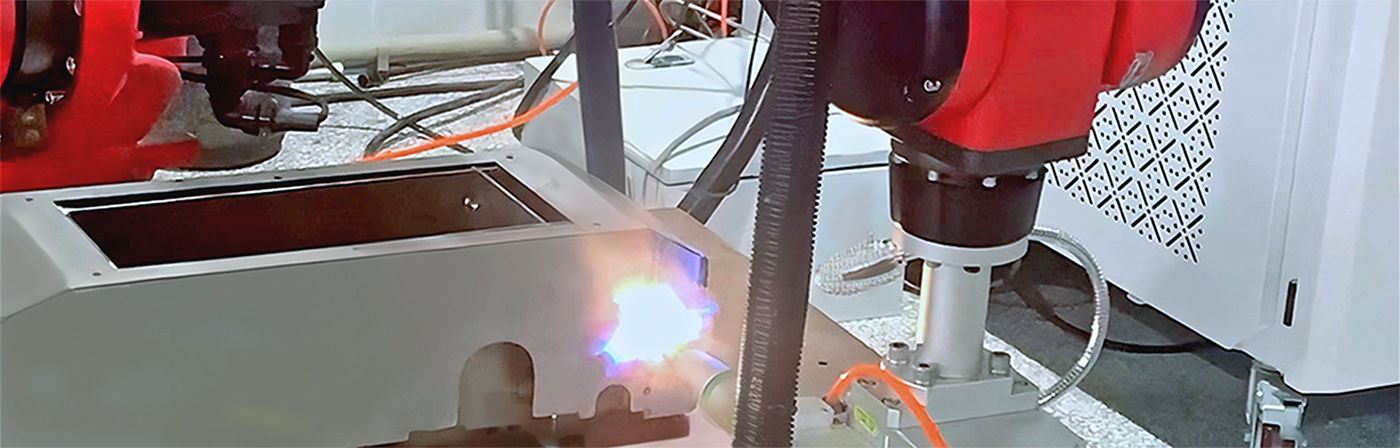

Ukuwelda indawo

-

Ukuwelda kweLaser

-

Ukugudisa

-

Ukusika

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu