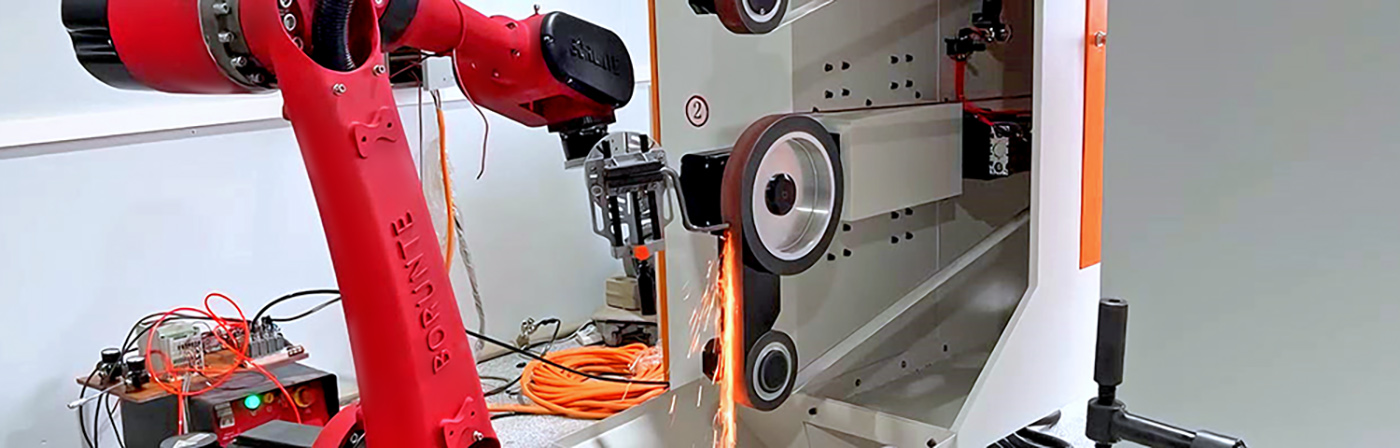

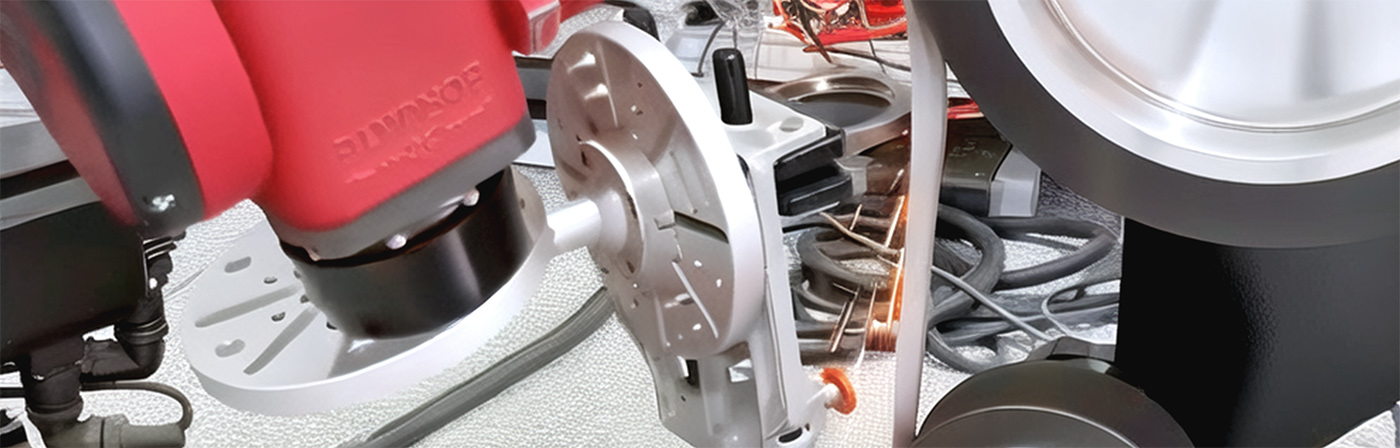

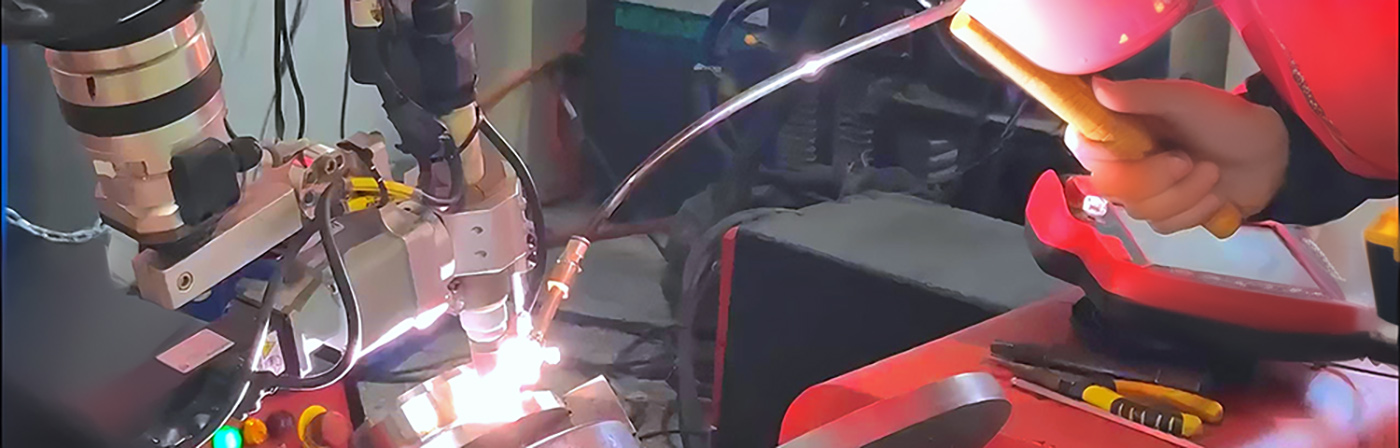

I-BRTIRPH1210A yirobhothi ene-axis emithandathu ephuhliswe ngu-BORUNTE ukwenzela i-welding, i-deburring kunye nokugaya izicelo zemizi-mveliso. I-compact in shape, incinci ngobukhulu, ilula ngesisindo, kunye nomthwalo ophezulu we-10kg kunye nobude bengalo ye-1225mm. Isandla sayo sithatha isakhiwo esingenanto, esenza ukuba i-wiring ibe lula kwaye intshukumo iguquguquke. Eyokuqala, eyesibini kunye neyesithathu idibeneyo zonke zixhotyiswe ngokunciphisa okuphezulu, kunye nesine, isihlanu kunye nesithandathu esidibeneyo sixhotyiswe ngezixhobo eziphezulu ezichanekileyo. Isantya esiphezulu esidibeneyo sivumela ukusebenza okuguquguqukayo. Umgangatho wokhuseleko ufikelela kwi-IP54. Ukuthintela uthuli kunye nokungangeni kwamanzi. Ukuphinda ukuchaneka kokumisa yi-±0.07mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±165° | 164°/s | |

| J2 | -95 ° /+70 ° | 149°/s | ||

| J3 | ±80° | 185°/s | ||

| Isandla | J4 | ±155° | 384°/s | |

| J5 | -130 ° /+120 ° | 396°/s | ||

| J6 | ±360° | 461°/s | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) |

| 1225 | 10 | ±0.07 | 4.30 | 155  1. Ziziphi iingenelo zokuthenga ingalo yerobhothi yokupholisha yobungcali? I-BORUNTE iirobhothi zamashishini zokupolisha zinokuphucula ukusebenza kakuhle kwemveliso, ukuphucula umgangatho wemveliso, ukunciphisa iindleko zabasebenzi kunye neengozi zeempazamo zabantu, zinokusebenza kwiqondo lokushisa eliphezulu, igesi eyingozi kunye nezinye iindawo zokubonelela ngokukhuselekileyo kwendawo yokusebenza. 2. Indlela yokukhetha irobhothi yoshishino yokupholisha ehambelana neemfuno zakho? Xa ukhetha i-robot, ezi zinto zilandelayo kufuneka ziqwalaselwe: umthwalo womsebenzi, indawo yokusebenza, iimfuno zokuchaneka, isantya sokusebenza, iimfuno zokhuseleko, ukucwangciswa kweprogram kunye nokusebenza ngokulula, iimfuno zokugcina, kunye nemiqobo yebhajethi. Kwangaxeshanye, uthethwano kufuneka kwakhona luqhutywe kunye nababoneleli kunye neengcali ukufumana iingcebiso ezicacileyo. Iimpawu ezibalulekileyo zengalo yerobhothi yokupholisha yobuNgcali: 1. Ukuchaneka kunye nokuphindaphinda: Umsebenzi wokugulisa ngokuqhelekileyo ufuna intshukumo echanekileyo kunye nokusebenza okungaguqukiyo. Iirobhothi zoshishino zinokubeka kwaye zilawule ngokuchaneka kwenqanaba le-millimeter, ukuqinisekisa iziphumo ezihambelanayo kuwo wonke umsebenzi. 2. Ukuzenzekelayo kunye nokusebenza kakuhle: Enye yeenjongo eziphambili zeerobhothi zoshishino kukuphucula ukusebenza kakuhle kwemveliso. Inkqubo yokupholisha idla ngokuba nzima kwaye ichitha ixesha, kodwa iirobhothi zinokwenza imisebenzi ngokukhawuleza nangendlela ehambelanayo, ngaloo ndlela iphucula ukusebenza kakuhle komgca wemveliso.

Iindidi zeemvelisoI-BORUNTE kunye ne-BORUNTE abahlanganisiKwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

|