Irobhothi yodidi lwe-BRTIRWD1606A yirobhothi enemigca emithandathu ephuhliswe nguBORUNTE kushishino lwesicelo sokuwelda. Irobhothi ibumbene, incinci ngokobukhulu kwaye ilula ngobunzima. Umthwalo wayo omkhulu yi-6kg kwaye ubude bengalo yi-1600mm. Isakhiwo esingenamngxuma esihlahleni, umgca olungele ngakumbi, isenzo esibhetyebhetye ngakumbi. Eyokuqala, eyesibini kunye neyesithathu idibeneyo ixhotyiswe ngokunciphisa okuphezulu okuphezulu, kunye nesine, isihlanu kunye nesithandathu esidibeneyo sixhotyiswe ngezakhiwo zegiya ezichanekileyo, ngoko ke isantya esiphezulu esidibeneyo sinokuqhuba imisebenzi eguquguqukayo. Umgangatho wokhuseleko ufikelela kwi-IP54. Ukuthintela uthuli kunye nokungangeni kwamanzi. Ukuphinda ukuchaneka kokumisa yi-±0.05mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±165° | 158°/s | |

| J2 | -95 ° / + 70 ° | 143°/s | ||

| J3 | ±80° | 228°/s | ||

| Isandla | J4 | ±155° | 342°/s | |

| J5 | -130 ° / + 120 ° | 300°/s | ||

| J6 | ±360° | 504°/s | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) |

| 1600 | 6 | ±0.05 | 6.11 | 157 |

Unokukhetha njani izixhobo zerobhothi zokuwelda kwishishini?

1. Chonga inkqubo yokuwelda: Qinisekisa inkqubo yokuwelda oza kuyisebenzisa, njenge-MIG, TIG, okanye i-spot welding. Iinkqubo ezahlukeneyo zinokufuna iindidi ezahlukeneyo zokulungisa.

2. Qonda iinkcukacha zecandelo lomsebenzi: Hlalutya imilinganiselo, imilo, kunye nempahla yomsebenzi ekufuneka idityaniswe. Isixhobo kufuneka sibambe kwaye sibambe ngokukhuselekileyo isiqwenga somsebenzi ngexesha le-welding.

3. Qwalasela iindidi zokudityaniswa kwe-welding: Qinisekisa iindidi zamalungu (umzekelo, i-butt joint, i-lap joint, i-joint joint) uya kuba ne-welding, njengoko oku kuya kuba nefuthe kuyilo kunye nokwakheka kwe-fixture.

4. Vavanya umthamo wemveliso: Qwalasela umthamo wemveliso kunye namaxesha okuza kusetyenziswa ngawo isilungiso. Ukuvelisa umthamo ophezulu, ukulungiswa okuzinzileyo kunye nokuzenzekelayo kunokufuneka.

5. Ukuvavanya iimfuno zokuchaneka kwe-welding: Qinisekisa izinga lokuchaneka okufunekayo kwiprojekthi ye-welding. Ezinye izicelo zinokufuna unyamezelo oluqinileyo, oluya kuba nefuthe kuyilo nolwakhiwo lwesixhobo.

Uyilo ngokubanzi lweBRTIRWD1606A

I-BRTIRWD1606A ithatha ulwakhiwo lwerobhothi edibeneyo emithandathu, iimoto ezintandathu ze-servo ziqhuba ukujikeleza kwee-axes ezidibeneyo ezintandathu ngokunciphisa kunye nezixhobo. Inemilinganiselo emithandathu yenkululeko, oko kukuthi ukujikeleza (X), ingalo esezantsi (Y), ingalo engaphezulu (Z), ukujikelezisa isihlahla (U), ukujiwuzisa isihlahla (V), nokujikeleza kwesihlahla (W).

I-BRTIRWD1606A idibaniso yomzimba yenziwe nge-aluminiyam etyhidiweyo okanye intsimbi, iqinisekisa amandla aphezulu, isantya, ukuchaneka, kunye nokuzinza kwerobhothi.

-

Ukuwelda indawo

-

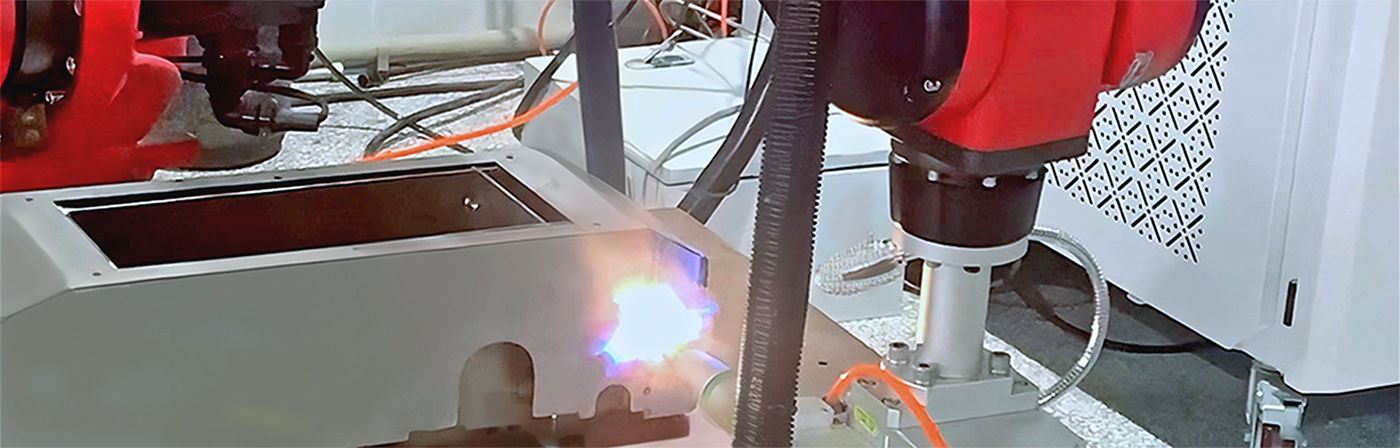

Ukuwelda kweLaser

-

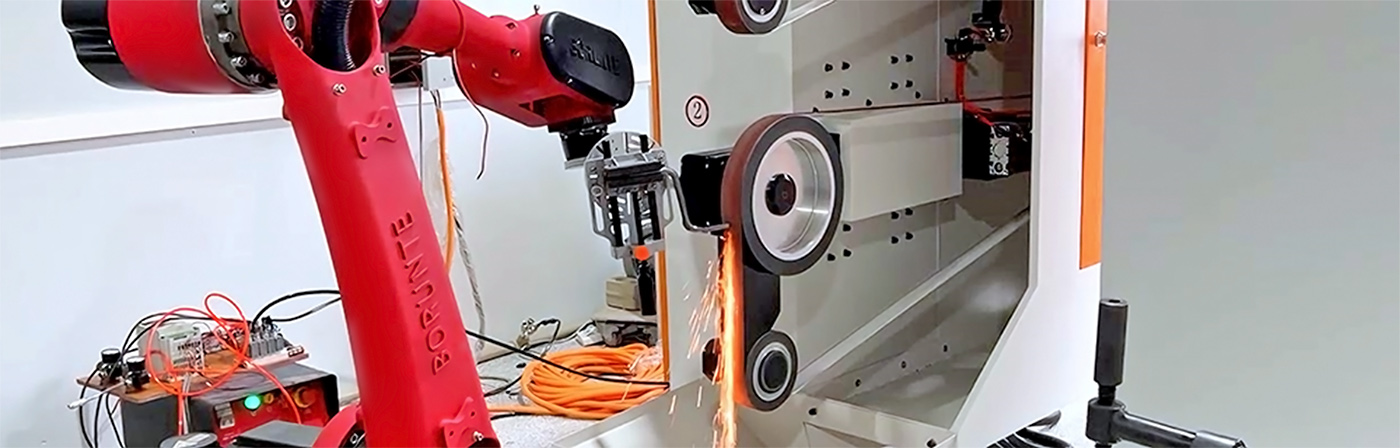

Ukugudisa

-

Ukusika

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu