Irobhothi yodidi lwe-BRTIRWD2206A yirobhothi enemigca emithandathu ephuhliswe nguBORUNTE kushishino lwesicelo sokuwelda. Irobhothi ibumbene, incinci ngokobukhulu kwaye ilula ngobunzima. Umthwalo wayo omkhulu yi-6kg kwaye ubude bengalo yi-2200mm. Isakhiwo esingenamngxuma esihlahleni, umgca olungele ngakumbi, isenzo esibhetyebhetye ngakumbi. Umgangatho wokhuseleko ufikelela kwi-IP54 esihlahleni kunye ne-IP40 emzimbeni. Ukuphinda ukuchaneka kokubeka ngu-±0.08mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±155° | 106°/s | |

| J2 | -130 ° / + 68 ° | 135°/s | ||

| J3 | -75 °/+110 ° | 128°/s | ||

| Isandla | J4 | ±153° | 168°/s | |

| J5 | -130 ° / + 120 ° | 324°/s | ||

| J6 | ±360° | 504°/s | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) |

| 2200 | 6 | ±0.08 | 5.38 | 237 |

Ubude bengalo buchaphazela njani ukusetyenziswa kwe-welding?

I-1.Reach kunye ne-Workspace: Ingalo ende ivumela i-robot ukuba ifikelele kwindawo enkulu yokusebenza, eyenza ukuba ifikelele kwiindawo ezikude okanye eziyinkimbinkimbi ze-welding ngaphandle kokufuna ukutshintshwa rhoqo. Oku kwandisa ukusebenza kakuhle kwaye kunciphisa isidingo sokungenelela kwabantu.

2. Ukuguquguquka: Ubude bengalo ende bubonelela ngokuguquguquka okukhulu, okuvumela irobhothi ukuba iqhube kwaye idibanise imiqobo okanye kwiindawo ezixineneyo, iyenze ilungele ukuwelda izinto ezintsonkothileyo kunye nezingalungiswanga ngokungaqhelekanga.

3.Iziqwenga zoMsebenzi ezinkulu: Iingalo ezinde zifaneleke ngcono ukuwelda amaqhekeza omsebenzi amakhulu kuba zinokugubungela indawo eninzi ngaphandle kokubeka indawo ngokutsha. Oku kunenzuzo kumashishini apho amacandelo amakhulu olwakhiwo kufuneka adityaniswe.

I-4.Ukufikelela ngokudibeneyo: Kwezinye izicelo ze-welding, kukho ii-angles ezithile okanye ii-joints ezinokuba ngumngeni ukufikelela kunye ne-robot-arm short. Ingalo ende inokufikelela kwaye idibanise la malungu anzima ukufikelela ngokulula.

I-5.Uzinzo: Iingalo ezinde ngamanye amaxesha ziyakwazi ukuxubha kunye nokuphambuka, ngakumbi xa ujongene nomthwalo onzima okanye ukwenza i-welding ye-speed-speed. Ukuqinisekisa ukuqina okwaneleyo kunye nokuchaneka kubalulekile ukugcina umgangatho we-welding.

I-6.Isantya se-Welding: Kwiinkqubo ezithile ze-welding, i-robot yengalo emide ingaba nezantya eziphezulu zomgca ngenxa yendawo enkulu yokusebenza, enokunyusa imveliso ngokunciphisa amaxesha okujikeleza kwe-welding.

Umgaqo osebenzayo weerobhothi zokuwelda:

Iirobhothi ze-welding zikhokelwa ngabasebenzisi kwaye zisebenza inyathelo ngenyathelo ngokwemisebenzi yokwenyani. Ngethuba lenkqubo yesikhokelo, i-robot ikhumbula ngokuzenzekelayo isikhundla, i-posture, i-parameters eshukumayo, i-welding parameters, njl njl kwisenzo ngasinye esifundiswayo, kwaye ngokuzenzekelayo ivelise inkqubo eqhuba ngokuqhubekayo yonke imisebenzi. Emva kokugqiba ukufundisa, vele unike irobhothi umyalelo wokuqala, kwaye irobhothi iya kulandela ngokuchanekileyo isenzo sokufundisa, inyathelo ngenyathelo, ukugqiba yonke imisebenzi, ukufundisa kwangempela kunye nokuzala.

-

Ukuwelda indawo

-

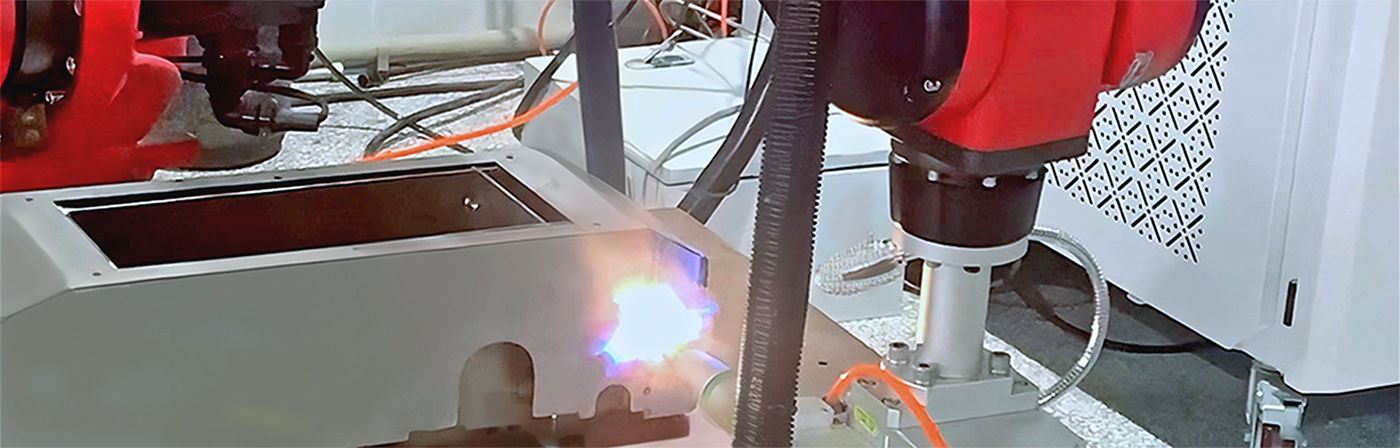

Ukuwelda kweLaser

-

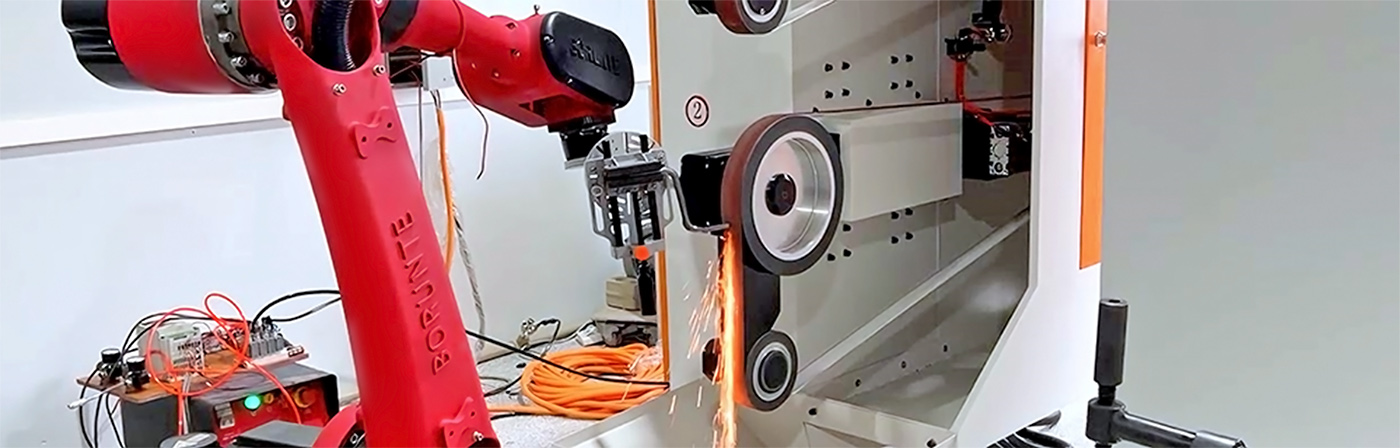

Ukugudisa

-

Ukusika

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu