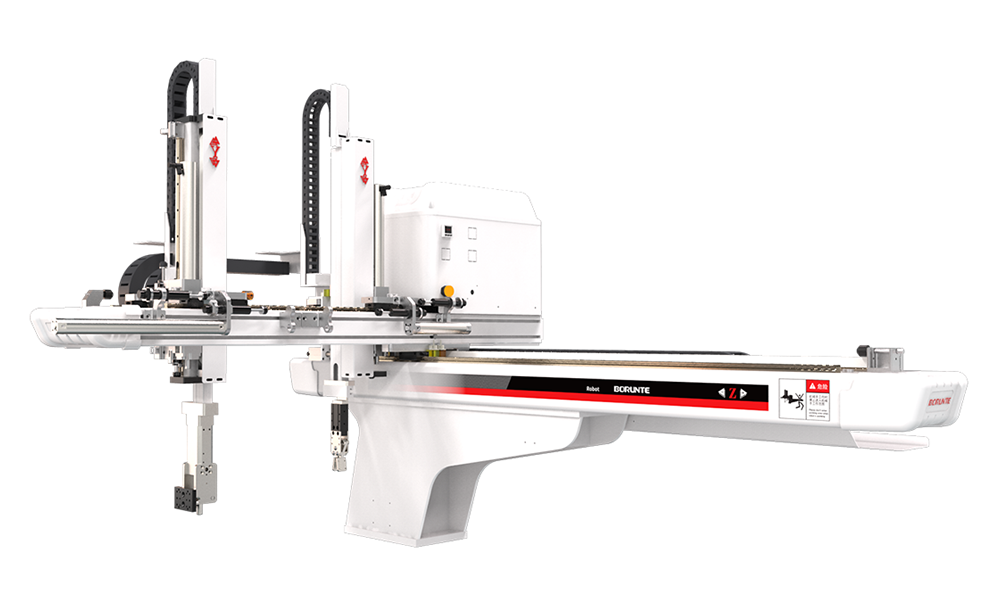

I-BRTB06WDS1P0/F0 ingalo yerobhothi enqumlayo isebenza kuzo zonke iindidi zomatshini wokutofa othe tyaba we-30T-120T kwiimveliso zokuthatha kunye ne-sprue. Ingalo ethe nkqo luhlobo lwe telescopic, enengalo yemveliso kunye nengalo yombaleki, iipleyiti ezimbini okanye ezintathu iimveliso zokungunda zithatha. I-axis enqumlayo iqhutywa yi-AC servo motor. Ukuma okuchanekileyo, isantya esikhawulezayo, ubomi obude, kunye nesantya esisezantsi sokungaphumeleli. Ukufakela i-manipulator, imveliso iya kwandiswa nge-10-30% kwaye iya kunciphisa izinga eliphosakeleyo leemveliso, ukuqinisekisa ukhuseleko lwabaqhubi, ukunciphisa abasebenzi kunye nokulawula ngokuchanekileyo imveliso yokunciphisa inkunkuma.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Umthombo wamandla (KVA) | I-IMM ecetyiswayo (itoni) | Ukunqumla kuqhutywa | Umzekelo we-EOAT |

| 1.69 | 30T-120T | Injini ye-AC Servo | ifunxa enye into enye |

| I-Traverse Stroke (mm) | I-Crosswise Stroke (mm) | IStrowuku esithe nkqo (mm) | Ubukhulu.ukulayisha (kg) |

| 1100 | P:200-R:125 | 600 | 3 |

| Ixesha Lokukhupha Likhuphe (umzuzwana) | Ixesha loMjikelo owomileyo (umzuzwana) | Ukusetyenziswa koMoya (NI/umjikelo) | Ubunzima (kg) |

| 1.6 | 5.8 | 3.5 | 175 |

Ukumelwa komzekelo: W: Uhlobo lweTelescopic. D: Ingalo yemveliso +ingalo yembaleki. I-S5: I-axis emihlanu eqhutywa yi-AC Servo Motor (i-Traverse-axis, i-Vertical-axis + i-Crosswise-axis).

Ixesha lomjikelo elikhankanywe ngasentla ziziphumo zomgangatho wovavanyo lwangaphakathi lwenkampani yethu. Kwinkqubo yesicelo sangempela somatshini, ziya kuhluka ngokuhambelana nokusebenza kwangempela.

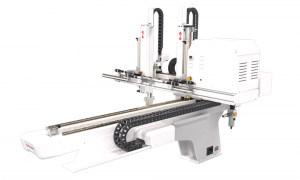

| A | B | C | D | E | F | G | H |

| 1200 | 1900 | 600 | 403 | 1100 | 355 | 165 | 210 |

| I | J | K | L | M | N | O | |

| 110 | 475 | 365 | 1000 | 242 | 365 | 933 |

Akukho saziso esongezelelweyo ukuba iinkcukacha kunye nenkangeleko zitshintshiwe ngenxa yokuphucula kunye nezinye izizathu. Enkosi ngokuqonda kwakho.

Indlela yokutshintshela kwimowudi yesandla kwaye uyisebenzise?

Ngenisa isikrini semanuwali, unokwenza umsebenzi owenziwe ngesandla, usebenzise i-manipulator ukuba isebenze isenzo ngasinye, kwaye ulungelelanise indawo nganye yomatshini (xa usebenza ngesandla, qinisekisa ukuba kukho umqondiso wokuvula isikhunta ngaphambi kokuqhubeka, kwaye uqinisekise ukuba ukubumba ayichukunyiswa). Ukuqinisekisa ukhuseleko lwee-manipulators kunye neenaliti zokubumba umatshini wokubumba, kukho izithintelo ezilandelayo:

Emva kokuba i-robot yehla, ayikwazi ukwenza iintshukumo ezithe nkqo okanye ezithe tye.

Emva kokuba i-robot ihla, ayikwazi ukwenza intshukumo ethe tye. (Ngaphandle kwendawo yokhuseleko ngaphakathi kwimodeli) .

Ukuba akukho mqondiso wokuvulwa kwesikhunta, i-manipulator ayikwazi ukwenza intshukumo ehlayo kwi-mold.

Ugcino lokhuseleko (Qaphela):

Ngaphambi kokulungisa i-manipulator, abasebenzi bolondolozo nceda ufunde le ngcaciso yokhuseleko ilandelayo ukuphepha ingozi.

1.Nceda ucime amandla phambi kokuba ujonge umatshini wokutofa.

2.Ngaphambi kokulungiswa kunye nokugcinwa, nceda ucime umbane kunye noxinzelelo olushiyekileyo lomatshini we-injection kunye ne-manipulator.

3.Ukongezelela kwi-close switch, ukufunxa kakubi, ukungaphumeleli kwe-valve ye-solenoid kunokulungiswa ngokwabo, abanye kufuneka babe ngabasebenzi abaqeqeshiweyo abaqeqeshelwe ukulungisa, ngaphandle koko musa ukutshintsha ngaphandle kokugunyaziswa.

4. Nceda ungatshintshi okanye utshintshe iindawo zokuqala.

5.Ngexesha lohlengahlengiso lokubumba okanye utshintsho, nceda uqaphele ukhuseleko ukuze ugweme ukwenzakala yi-manipulator.

6.Emva kokulungelelanisa okanye ukulungisa i-manipulator, nceda ushiye indawo yokusebenza eyingozi ngaphambi kokuba uqalise.

7.Musa ukuvula amandla okanye udibanise i-compressor yomoya kwisandla somatshini.

-

Isitofu sokubumba

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu