Intshayelelo yeMveliso

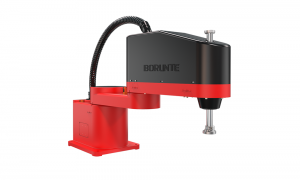

I-BRTIRPZ3116B yeirobhothi ezine axisiphuhliswe ngu-BORUNTE, ngesantya sokuphendula ngokukhawuleza kunye nokuchaneka okuphezulu. Umthwalo wayo ophezulu ngu-160KG kwaye ubude besandla esiphezulu bunokufikelela kwi-3100mm. Qonda iintshukumo ezinkulu ezinobumba obubambeneyo, obuguquguqukayo kunye neentshukumo ezichanekileyo. Ukusetyenziswa: Ifanelekile ukupakisha izinto kwiifom zokupakisha ezifana neengxowa, iibhokisi, iibhotile, njl njl. Ibanga lokukhusela lifikelela kwi-IP40. Ukuphinda ukuchaneka kokumisa yi-±0.5mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

Iiparamitha ezisisiseko

| Into | Uluhlu | Isantya esiphezulu | |

| Ingalo | J1 | ±158° | 120°/s |

| J2 | -84°/+40° | 120°/s | |

| J3 | -65 °/+25 ° | 108°/s | |

| Isandla | J4 | ±360° | 288°/s |

| I-R34 | 65 ° -155 ° | / | |

Itshathi yendlela

I-1.Imigaqo esisiseko kunye nemiba yoyilo ye-robot ye-axis emine

Q: Ingaba iirobhothi ezine zemizi-mveliso ziphumelela njani?

A: Iirobhothi ezine zemizi-mveliso zineentsimbi ezine ezidityanisiweyo, nganye iqulathe izinto ezinjengeenjini kunye nezinciphisi. Ngokulawula ngokuchanekileyo i-angle yokujikeleza kunye nesantya semoto nganye ngokusebenzisa isilawuli, intonga yokudibanisa kunye nesiphumo sokugqibela siqhutyelwa ukufezekisa izikhokelo ezahlukeneyo zokunyakaza. Ngokomzekelo, i-axis yokuqala inoxanduva lokujikeleza kwerobhothi, i-axes yesibini neyesithathu yenza ukuba ukwandiswa kunye nokugoba ingalo yerobhothi, kwaye i-axis yesine ilawula ukujikeleza kwesiphumo sokugqibela, ivumela i-robot ukuba ibe bhetyebhetye kwindawo ezintathu. -Isithuba sobukhulu.

Q: Zeziphi iingenelo zoyilo lwe-axis ezine xa kuthelekiswa nezinye iirobhothi zokubala?

A: Iirobhothi ezine zeshishini zinesakhiwo esilula kunye nexabiso eliphantsi. Inokusebenza okuphezulu kwezinye iimeko zesicelo esithile, njengokuphindaphinda imisebenzi yeplani okanye i-3D elula yokuchola kunye nokubeka imisebenzi, apho irobhothi ye-axis emine inokugqiba ngokukhawuleza nangokuchanekileyo izenzo. I-algorithm yayo ye-kinematic ilula, kulula ukuyicwangcisa kunye nokulawula, kwaye iindleko zokugcinwa nazo ziphantsi.

Q: Ingaba indawo yokusebenza yerobhothi yemizi-mveliso emine imiselwe?

A: Indawo yokusebenzela imiselwe ikakhulu luluhlu lwentshukumo yejoyini nganye yerobhothi. Kwi-robot ye-axis emine, uluhlu lwe-angle yokujikeleza ye-axis yokuqala, ukwandiswa kunye noluhlu lokugoba lwe-axs yesibini neyesithathu, kunye noluhlu lokujikeleza lwe-axis yesine ngokudibeneyo luchaza indawo ye-spatial ye-dimensional emithathu enokufikelela kuyo. Imodeli ye-kinematic ingabala ngokuchanekileyo indawo yomphumo we-robot kwiindawo ezahlukeneyo, ngaloo ndlela imisela indawo yokusebenza.

2.Imeko yesicelo enxulumene nemiba yerobhothi yokuthengisa ipalletizing BRTIRPZ3116B

Q: Ngawaphi amashishini alungele iirobhothi ezine ze-axis?

A: Kumashishini ombane, iirobhothi ezine ze-axis zingasetyenziselwa imisebenzi efana nokufaka iibhodi zeesekethe kunye nokudibanisa amacandelo. Kwishishini lokutya, inokwenza imisebenzi efana nokuhlelwa kunye nokupakishwa kokutya. Kwintsimi ye-logistics, kunokwenzeka ukupakisha ngokukhawuleza nangokuchanekileyo iimpahla. Kwimveliso yamacandelo emoto, imisebenzi elula efana ne-welding kunye nokuphathwa kwamacandelo inokwenziwa. Ngokomzekelo, kumgca wokuvelisa ifowuni ephathwayo, i-robot ye-axis emine inokukhawuleza ukufaka ii-chips kwiibhodi zeesekethe, ukuphucula ukusebenza kakuhle kwemveliso.

Umbuzo: Ngaba iirobhothi ezine ze-axis ziyakwazi ukusingatha imisebenzi yendibano enzima?

A: Kwezinye iindibano ezilula nezintsonkothileyo, ezinje ngokudityaniswa kwecandelo ngokuthe rhoqo, irobhothi ezine axis zinokugqitywa ngokucwangciswa kwenkqubo kunye nokusetyenziswa kweziphumo ezifanelekileyo. Kodwa kwimisebenzi yendibano entsonkothileyo efuna idigri yenkululeko enezikhokelo ezininzi kunye nokuphathwa kakuhle, iirobhothi ezineezembe ezininzi zinokufuneka. Nangona kunjalo, ukuba imisebenzi yendibano entsonkothileyo yahlulahlulwe yangamanyathelo amaninzi alula, irobhothi emine ye-axis isenokuthi idlale indima kwimiba ethile.

Umbuzo: Ngaba iirobhothi ezine ze-axis zingasebenza kwindawo ezinobungozi?

A: ngokuqinisekileyo. Ngokusebenzisa imilinganiselo yoyilo ekhethekileyo efana neenjini zokudubula kunye neendawo zokukhusela, iirobhothi ezine ze-axis zingenza imisebenzi kwiindawo ezinobungozi, ezifana nokuphatha izinto okanye imisebenzi elula kwiindawo ezithile ezinokutsha kunye neziqhushumbisi kwimveliso yeekhemikhali, ukunciphisa umngcipheko wokuvezwa kwabasebenzi engozini.

-

Ezothutho

-

isitampu

-

Isitofu sokungunda

-

ukupakisha

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu