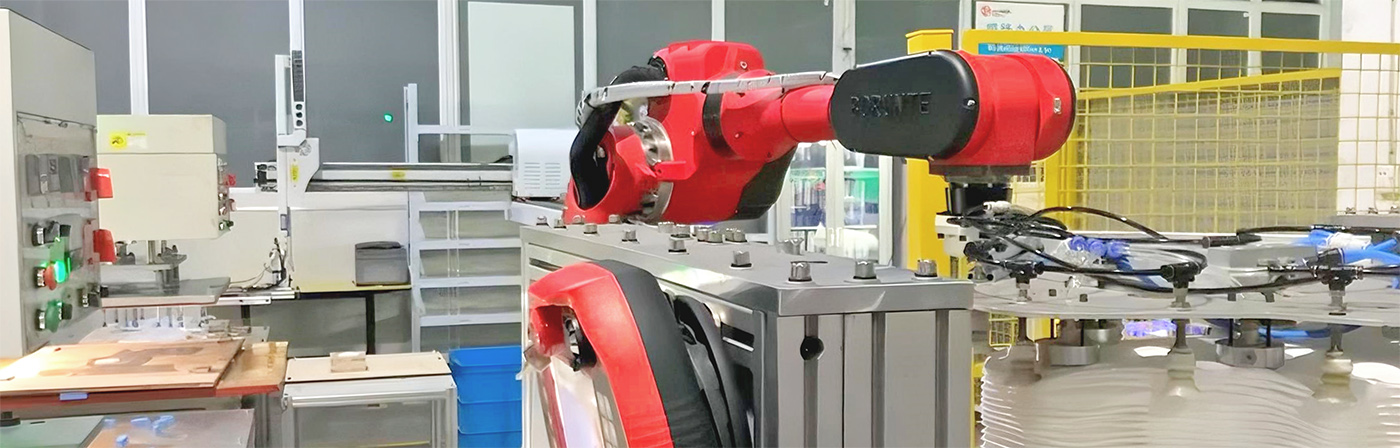

Irobhothi yohlobo lwe-BRTIRPZ2250A yirobhothi ene-axis emine eyaphuhliswa ngu-BORUNTE ukwenzela imisebenzi emnandi, ehlala ihleli kwaye iphinda-phinda ixesha elide okanye imisebenzi kwiindawo ezinobungozi nezingqwabalala.Ubude bobude bengalo yi-2200mm.Umthwalo ophezulu yi-50KG.Iyabhetyebhetye ngamaqondo amaninzi enkululeko.Ilungele ukulayishwa kunye nokukhulula, ukuphatha, ukudilizwa kunye nokupakisha njl njl. Ibanga lokukhusela lifikelela kwi-IP50.Ubungqina bothuli.Ukuphinda ukuchaneka kokubeka ngu-±0.1mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±160° | 84°/s | |

| J2 | -70°/+20° | 70°/s | ||

| J3 | -50 °/+30 ° | 108°/s | ||

| Isandla | J4 | ±360° | 198°/s | |

| I-R34 | 65 ° -160 ° | / | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kva) | Ubunzima (kg) |

| 2200 | 50 | ±0.1 | 12.94 | 560 |

1. Isishwankathelo soPhononongo lweZiro Point

Ulungelelwaniso lwenqaku elinguziro libhekiselele kumsebenzi owenziweyo ukunxulumanisa i-engile yerobhothi nganye ehamba nexabiso le-encoder count.Injongo yomsebenzi wokulinganisa u-zero kukufumana ixabiso le-encoder count ehambelana ne-zero position.

Uphononongo lwamanqaku aluziro lugqityiwe phambi kokuba umke kumzi-mveliso.Kwimisebenzi yemihla ngemihla, ngokuqhelekileyo akukho mfuneko yokwenza imisebenzi yokulinganisa i-zero.Nangona kunjalo, kwiimeko ezilandelayo, umsebenzi wokulinganisa i-zero kufuneka wenziwe.

① Ukutshintsha injini

② Ukutshintshwa kwekhowudi okanye ukusilela kwebhetri

③ Ukutshintshwa kweyunithi yesixhobo

④ Ukutshintshwa kwentambo

2. Indlela yokulinganisa inqaku elingu-Zero

Ukulinganisa inqaku elingu-zero yinkqubo entsonkothileyo noko.Ngokusekwe kwimeko yangoku eyiyo kunye neemeko zenjongo, oku kulandelayo kuya kwazisa izixhobo kunye neendlela zokulinganisa amanqaku angu-0, kunye neengxaki eziqhelekileyo kunye neendlela zokuzisombulula.

① Ulungelelwaniso lwe-zero lweSoftware:

Kuyimfuneko ukusebenzisa i-laser tracker ukuseka inkqubo yokulungelelanisa yejoyinti nganye yerobhothi, kwaye usete inkqubo yokufunda i-encoder kwi-zero.Ulungelelwaniso lwesoftware luntsonkothile kwaye lufuna ukuqhutywa ngabasebenzi abaqeqeshiweyo benkampani yethu.

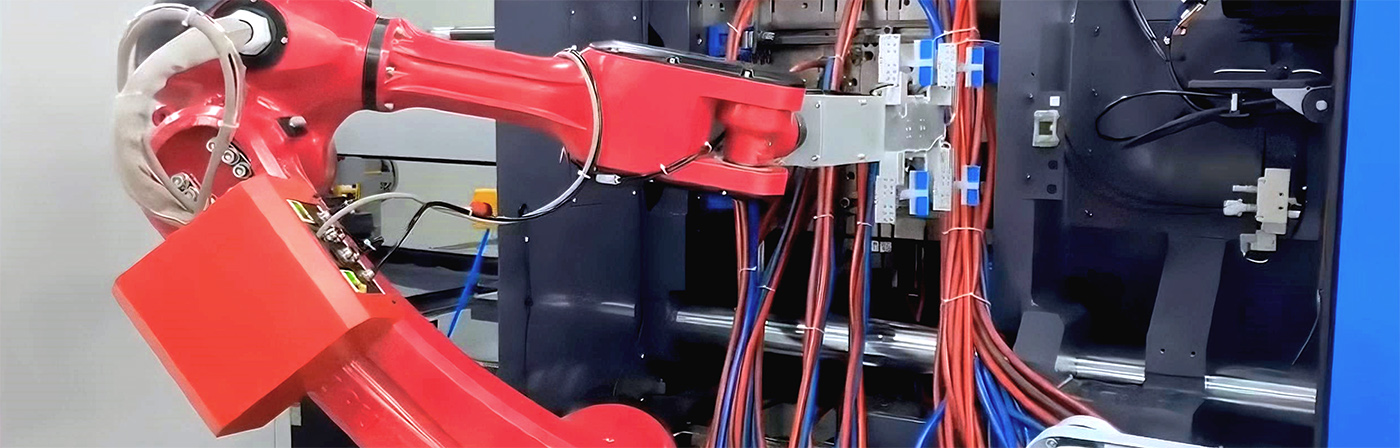

② Ulungelelwaniso lweziro lukamatshini:

Jikelezisa naziphi na iizembe ezimbini zerobhothi kwindawo yemvelaphi esetwe kwangaphambili yomzimba womatshini, kwaye emva koko ubeke iphini yemvelaphi ukuqinisekisa ukuba iphini yemvelaphi inokufakwa ngokulula kwindawo yemvelaphi yerobhothi.

Enyanisweni, isixhobo sokulinganisa i-laser kufuneka sisetyenziswe njengomgangatho.Isixhobo sokulinganisa i-laser sinokuphucula ukuchaneka komatshini.Xa usebenzisa iimeko zesicelo ezichanekileyo, ukulinganisa kwe-laser kufuneka kwenziwe kwakhona;Ukuma kwemvelaphi yoomatshini kukhawulelwe kwiimfuno ezisezantsi zokuchaneka kweemeko zokusetyenziswa komatshini.

-

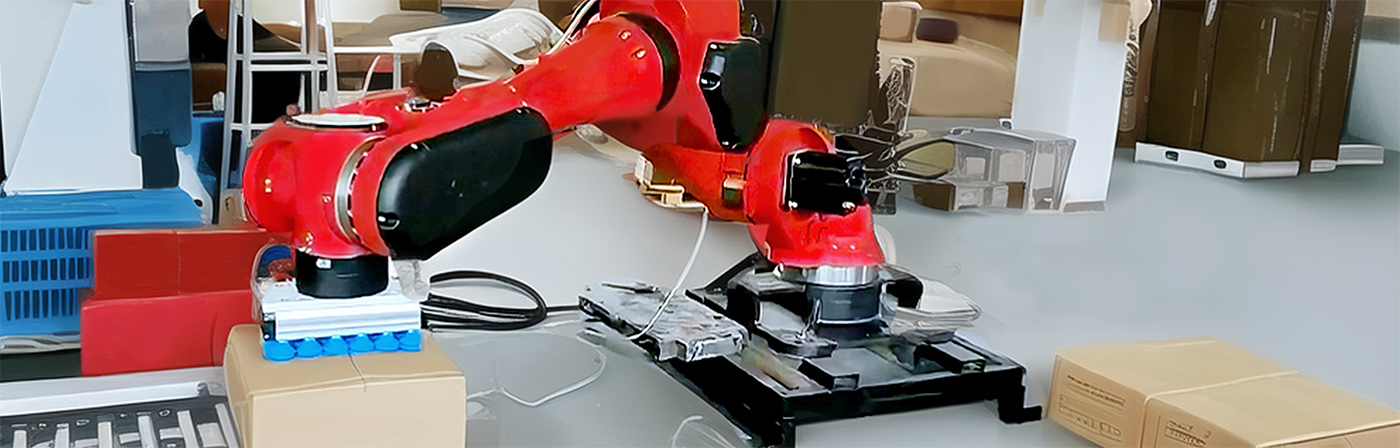

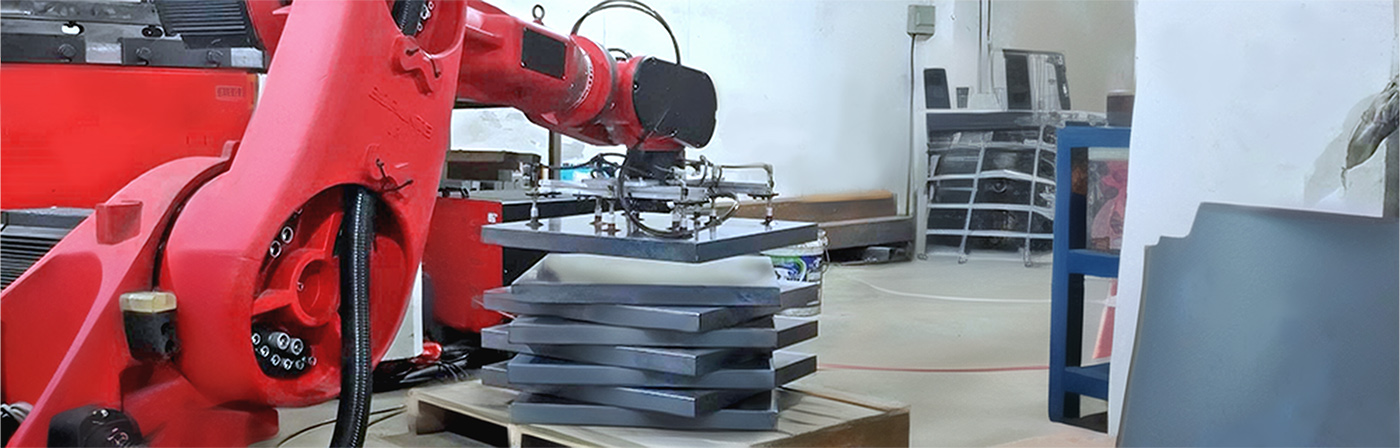

Ezothutho

-

isitampu

-

Isitofu sokungunda

-

ukupakisha

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators.Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo.Abadibanisi be-BORUTE kunye ne-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu