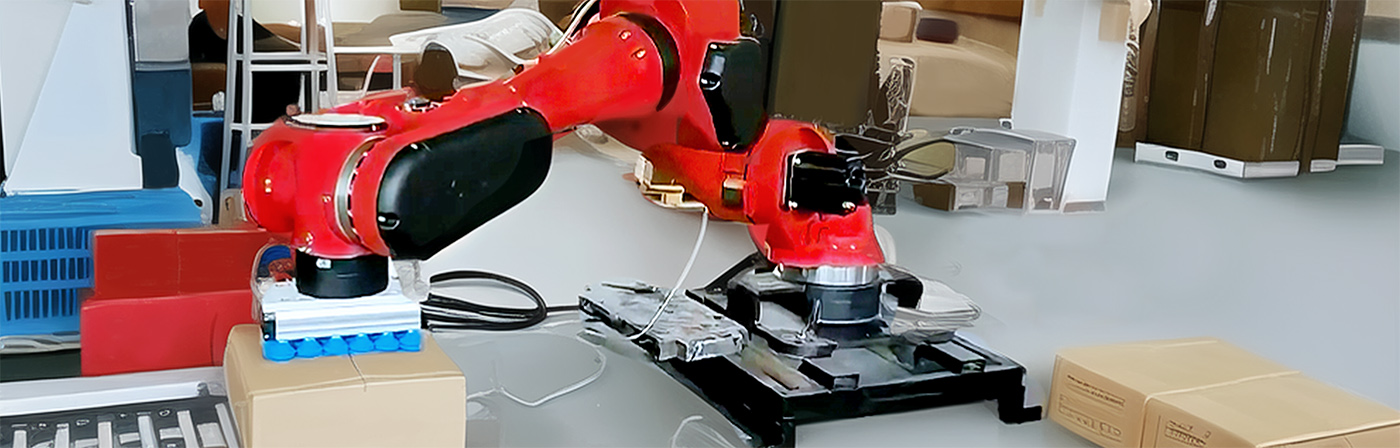

I-robot yohlobo lwe-BRTIRPL1003A yi-robot ye-axis e-four ephuhliswe ngu-BORUNTE yokuhlanganisa, ukuhlela kunye nezinye iimeko zesicelo zokukhanya, ezincinci kunye nezihlakazekileyo. Ubude bobude bengalo yi-1000mm kunye nomthwalo ophezulu yi-3kg. Umgangatho wokhuseleko ufikelela kwi-IP40. Ukuphinda ukuchaneka kokubeka ngu-±0.1mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Uluhlu | Isantya esiphezulu | ||

| Master Arm | Phezulu | Ukunyuka komphezulu ukuya kumgama we-872.5mm | 46.7° | stroke: 25/305/25 (mm) | |

| Hem | 86.6° | ||||

| Isiphelo | J4 | ±360° | Ixesha le-150 / min | ||

|

| |||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) | |

| 1000 | 3 | ±0.1 | 3.18 | 104 | |

1.Yintoni irobhothi enxuseneyo enemigca emine?

I-robot ye-four-axis parallel luhlobo lwe-robotic mechanism equkethe amalungu amane alawulwa ngokuzimeleyo okanye iingalo ezidityaniswe kwilungiselelo elifanayo. Yenzelwe ukubonelela ngokuchaneka okuphezulu kunye nesantya kwizicelo ezithile.

2.Ziziphi iingenelo zokusebenzisa i-robot ye-four-axis parallel?

Iirobhothi ezine-axis parallel zibonelela ngezibonelelo ezinjengokuqina okuphezulu, ukuchaneka, kunye nokuphindaphinda ngenxa ye-kinematics yazo ehambelanayo. Ziyilungele imisebenzi efuna isantya esiphezulu kunye nokuchaneka, njengokuthatha indawo kunye nokusebenza, ukudibanisa, kunye nokuphatha izinto eziphathekayo.

3.Ziziphi ezona zicelo ziphambili zeerobhothi ezihambelanayo ezine-axis?

Iirobhothi ezine-axis ezinxuseneyo ziqhele ukusetyenziswa kumashishini afana nokuvelisa izinto zombane, ukudityaniswa kweemoto, amayeza, kunye nokwenziwa kokutya. Bagqwesa kwimisebenzi efana nokuhlela, ukupakisha, ukuncamathelisa, kunye nokuvavanya.

4.Isebenza njani i-kinematics ye-four-axis parallel robot?

I-kinematics ye-four-axis parallel robot ibandakanya ukuhamba kwamalungu okanye iingalo zayo kwi-parallel configuration. Isikhundla somphumo wokuphela kunye nokuqhelaniswa kunqunywe yintshukumo edibeneyo yala malungu, aphunyezwa ngokuyila ngokucophelela kunye nokulawula i-algorithms.

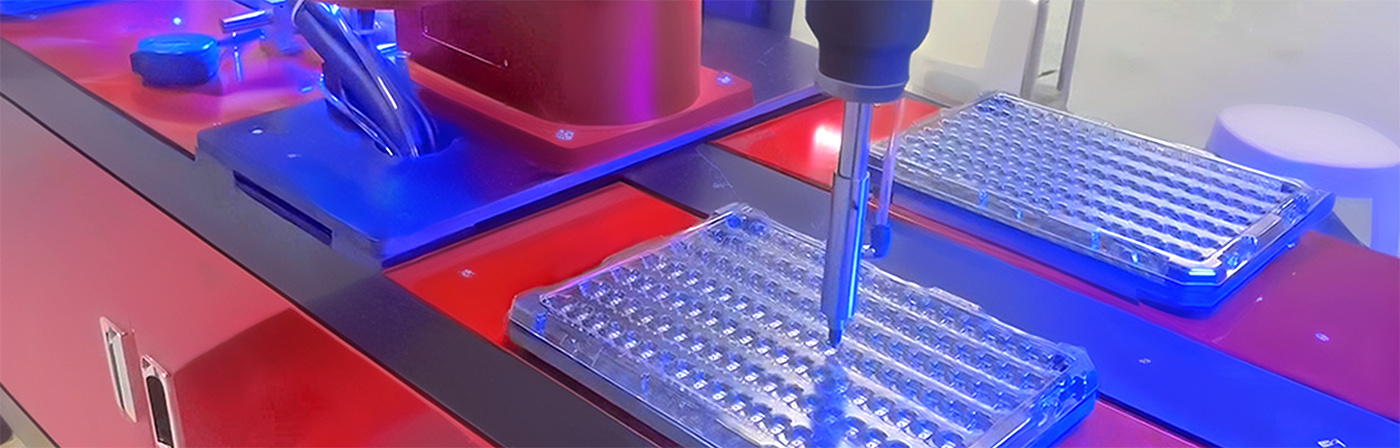

1.I-Lab Automation:

Iirobhothi ezine-axis parallel zisetyenziswa kwizicwangciso zelabhoratri kwimisebenzi efana nokuphatha iityhubhu zovavanyo, iivials, okanye iisampuli. Ukuchaneka kwabo kunye nesantya sibalulekile kumatshini wokuphindaphinda imisebenzi kuphando nakuhlalutyo.

2.Ukuhlela nokuHlola:

Ezi robhothi zinokusetyenzwa ekuhleleni izicelo, apho zinokukhetha kwaye zihlele izinto ngokusekelwe kwiikhrayitheriya ezithile, ezinjengobukhulu, imilo, okanye umbala. Basenokwenza uhlolo, bachonge iziphene okanye ukungahambelani kweemveliso.

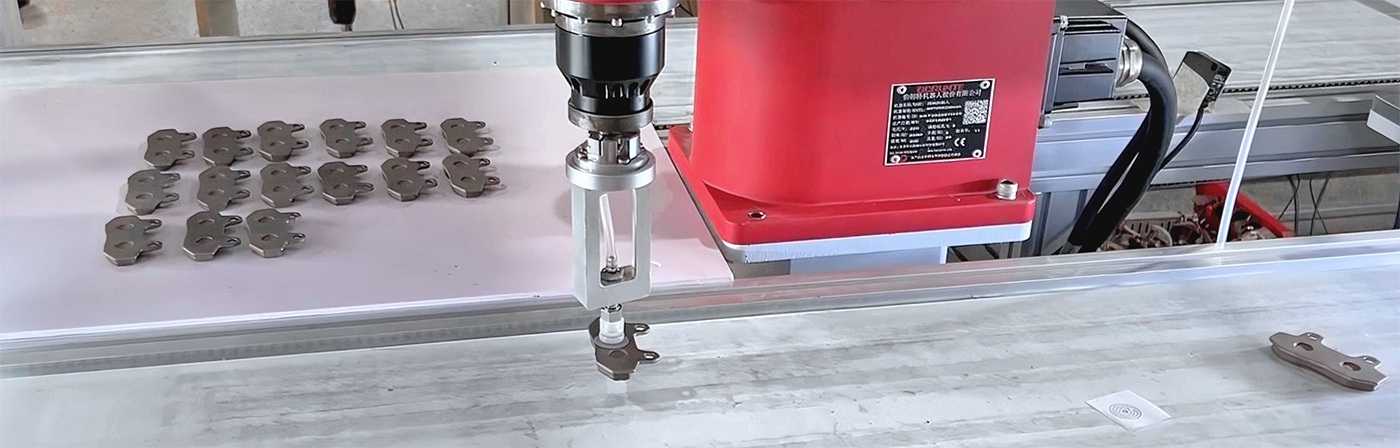

3.INdibano enesantya esiphezulu:

Ezi robhothi zilungele iinkqubo zokuhlanganisana ngesantya esiphezulu, njengokubeka amacandelo kwiibhodi zeesekethe okanye ukudibanisa izixhobo ezincinci. Ukunyakaza kwabo ngokukhawuleza kunye nokuchanekileyo kuqinisekisa ukusebenza ngokufanelekileyo komgca wendibano.

4.Ukupakishwa:

Kumashishini afana nokutya kunye nempahla yabathengi, iirobhothi ezine-axis parallel zinokupakisha ngokufanelekileyo iimveliso kwiibhokisi okanye kwiibhokisi. Isantya esiphezulu kunye nokuchaneka kwazo ziqinisekisa ukuba iimveliso zipakishwe ngokuqhubekayo nangokufanelekileyo.

-

Ezothutho

-

Ukufunyanwa

-

Umbono

-

Ukuhlela

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu