I-BRTIRUS1510A yi-robot ene-axis emithandathu ephuhliswe ngu-BORUNTE ukwenzela izicelo eziyinkimbinkimbi kunye needigri ezininzi zenkululeko. Umthwalo ophezulu ngu-10kg, ubude bengalo buyi-1500mm. Uyilo lwengalo yobunzima bokukhanya, i-compact kunye nesakhiwo esilula somatshini, kwisimo sokuhamba ngesantya esiphezulu, sinokuqhutyelwa kwindawo encinci yokusebenza eguquguqukayo, ukuhlangabezana neemfuno zemveliso eguquguqukayo. Inedigri ezintandathu zokuguquguquka. Ifanelekile ukupeyinta, i-welding, i-injection molding, i-stamping, i-forging, ukuphatha, ukulayisha, ukudibanisa, njl. Yamkela inkqubo yokulawula i-HC, ilungele umatshini wokubumba umjovo ukusuka kwi-200T-600T. Umgangatho wokukhusela ufikelela kwi-IP54. Ukuthintela uthuli kunye nokungangeni kwamanzi. Ukuphinda ukuchaneka kokumisa yi-±0.05mm.

Isikhundla Esichanekileyo

Ukukhawuleza

Ubomi Obude Benkonzo

Inqanaba lokusilela okuphantsi

Nciphisa uMsebenzi

Unxibelelwano ngocingo

| Into | Uluhlu | Isantya esiphezulu | ||

| Ingalo | J1 | ±165° | 190°/s | |

| J2 | -95 ° / + 70 ° | 173°/s | ||

| J3 | -85°/+75° | 223°/s | ||

| Isandla | J4 | ±180° | 250°/s | |

| J5 | ±115° | 270°/s | ||

| J6 | ±360° | 336°/s | ||

|

| ||||

| Ubude bengalo (mm) | Ukwazi ukuLayisha (kg) | Ukuchaneka kokuMisa okuphindiweyo (mm) | Umthombo wamandla (kVA) | Ubunzima (kg) |

| 1500 | 10 | ±0.05 | 5.06 | 150 |

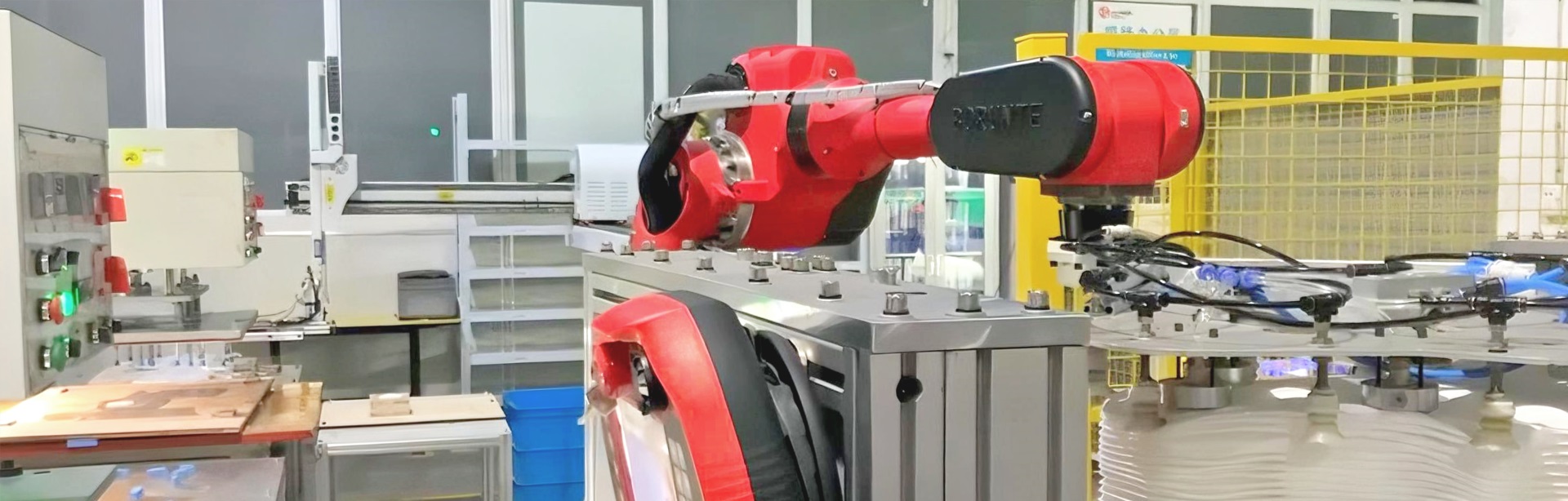

Ukusetyenziswa kwe-BRTIRUS1510A

1. Ukuphatha 2. Isitampu 3. Isitofu sokubumba 4. Ukusila 5. Ukusika 6. Ukuqhawula7. I-Gluing 8. Ukupakisha 9. Ukutshiza, njl.

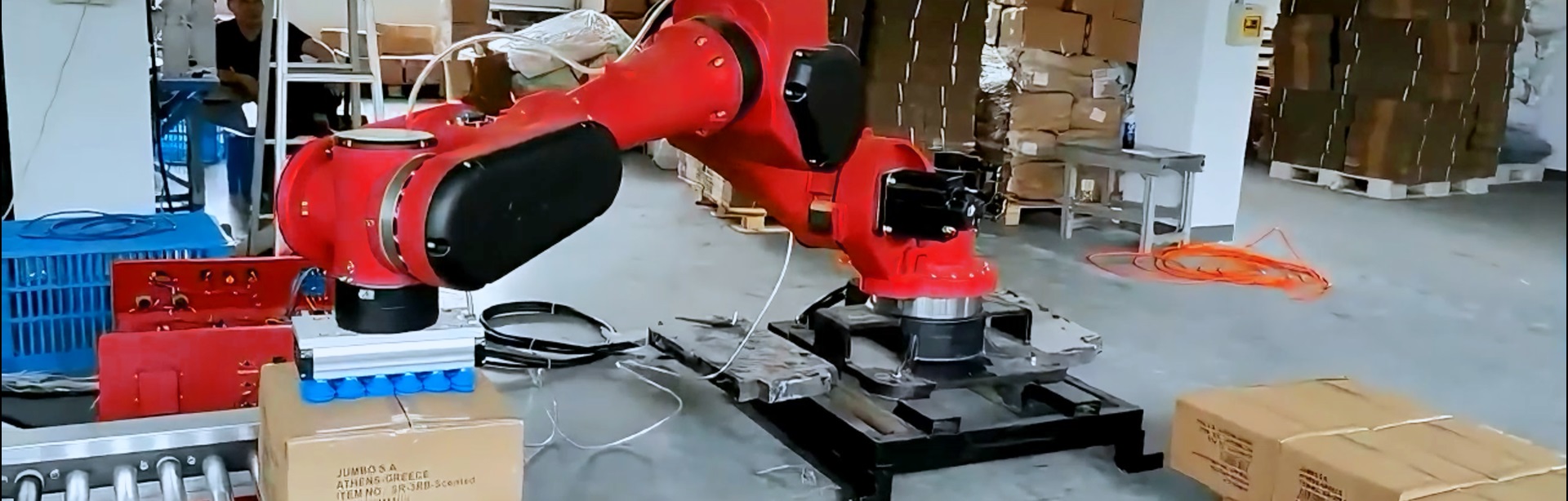

1.Ukuphatha izinto eziphathekayo: Iirobhothi zisetyenziselwa ukuphatha nokuthutha izinto ezinzima kwiifektri kunye neendawo zokugcina iimpahla. Bangakwazi ukuphakamisa, ukupakisha, kunye nokuhambisa izinto ngokuchanekileyo, ukuphucula ukusebenza kakuhle kunye nokunciphisa umngcipheko wokulimala emsebenzini.

I-2.I-Welding: Ngokuchaneka kwayo okuphezulu kunye nokuguquguquka, i-robot ifaneleke ngokufanelekileyo kwizicelo ze-welding, ibonelela nge-welds ezihambelanayo nezithembekileyo.

3.Ukutshiza: Iirobhothi zemizi-mveliso zisetyenziselwa ukupeyinta iindawo ezinkulu kumashishini afana neemoto, i-aerospace, kunye nempahla yabathengi. Ulawulo lwabo oluchanekileyo luqinisekisa ukugqitywa okufanayo kunye nomgangatho ophezulu.

I-4.Ukuhlolwa: Ukuhlanganiswa kwenkqubo yombono we-robot yenza ukuba yenze ukuhlolwa komgangatho, ukuqinisekisa ukuba iimveliso zihlangabezana nemigangatho ephezulu.

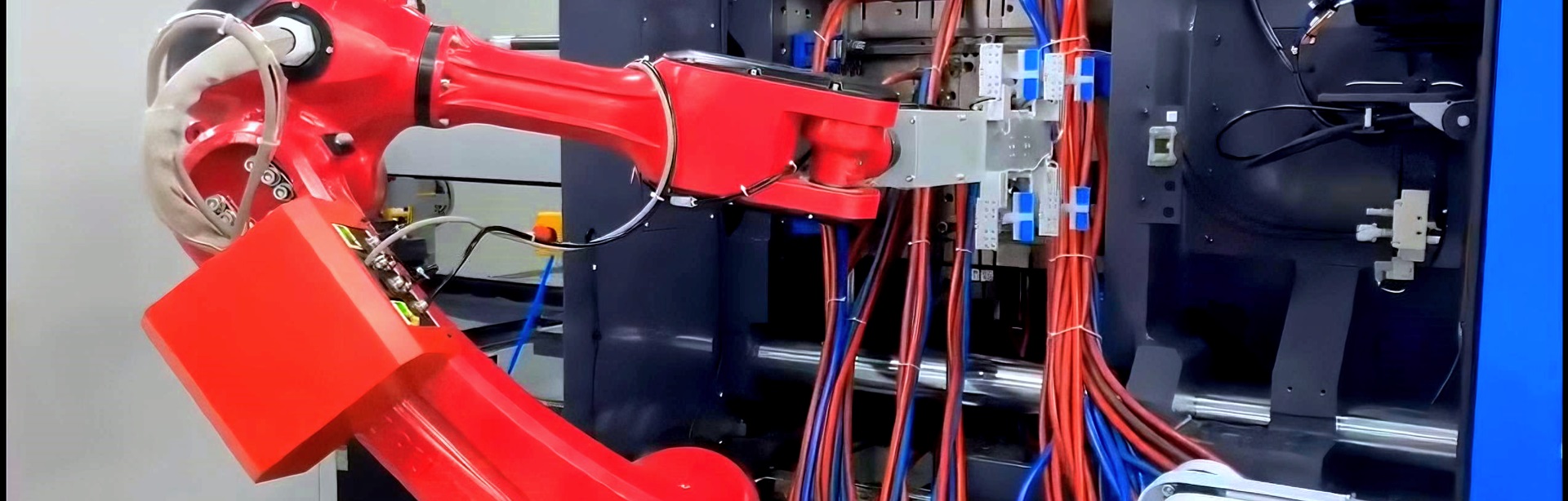

I-5.CNC Machining: I-BRTIRUS1510A inokudityaniswa kwi-Computer Numerical Control (CNC) kumatshini ukwenza imisebenzi enzima yokugaya, ukusika, kunye nokubhoboza ngokuchaneka okuphezulu kunye nokuphindaphinda.

Uvavanyo lokuhlolwa kwerobhothi ngaphambi kokuba ushiye umzi-mveliso we-BORUNTE:

I-1.I-Robot sisixhobo sokufakela esichanekileyo, kwaye akunakuphepheka ukuba iimpazamo ziya kwenzeka ngexesha lofakelo.

2.Irobhothi nganye kufuneka ifakwe kwi-precision instrument calibration monitoring kunye nokulungiswa kwembuyekezo phambi kokuba ihambe kumzi-mveliso.

3.Kuluhlu oluchanekileyo oluchanekileyo, ubude be-shaft, i-speed reducer, i-eccentricity kunye nezinye iiparitha zihlawulelwa ukuqinisekisa ukunyakaza kwezixhobo kunye nokuchaneka komkhondo.

I-4.Emva kokuba imbuyekezo yokulinganisa ingaphakathi kuluhlu olufanelekileyo (jonga itafile yokulinganisa ngeenkcukacha), ukuba ukuthunyelwa kwembuyekezo akukho phakathi koluhlu olufanelekileyo, luya kubuyiselwa kumgca wokuvelisa ukuhlalutya kwakhona, ukuchithwa kunye nokuhlanganisana, kwaye emva koko. ilinganiswe de ube ufanelekile.

-

uthutho

-

isitampu

-

Isitofu sokubumba

-

Polish

Iindidi zeemveliso

I-BORUNTE kunye ne-BORUNTE abahlanganisi

Kwi-ecosystem ye-BORUNTE, i-BORUNTE inoxanduva lwe-R&D, imveliso, kunye nokuthengisa iirobhothi kunye nee-manipulators. Abahlanganisi be-BORUNTE basebenzisa ishishini labo okanye izibonelelo zentsimi ukubonelela ngoyilo lwesicelo sesiphelo, ukudibanisa, kunye nenkonzo yasemva kokuthengisa kwiimveliso ze-BORUNTE abazithengisayo. I-BORUNTE kunye nabahlanganisi be-BORUNTE bazalisekisa uxanduva lwabo kwaye bazimeleyo omnye komnye, besebenza kunye ukukhuthaza ikamva eliqaqambileyo le-BORUNTE.

-

-

-

-

Phezulu