BRTIRUS3030A type robot is a six-axis robot developed by BORUNTE, the robot has a compact shape and structure, each joint is installed with a high precision reducer, high speed joint speed can be flexible operation, can carry out handling, palletizing, assembly, injection molding and other operations, has a flexible installation mode. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.07mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

89°/s |

|

|

J2 |

-105°/+60° |

85°/s |

||

|

J3 |

-75°/+115° |

88°/s |

||

|

Wrist |

J4 |

±180° |

245°/s |

|

|

J5 |

±120° |

270°/s |

||

|

J6 |

±360° |

337°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

3000 |

30 |

±0.07 |

5.07 |

860 |

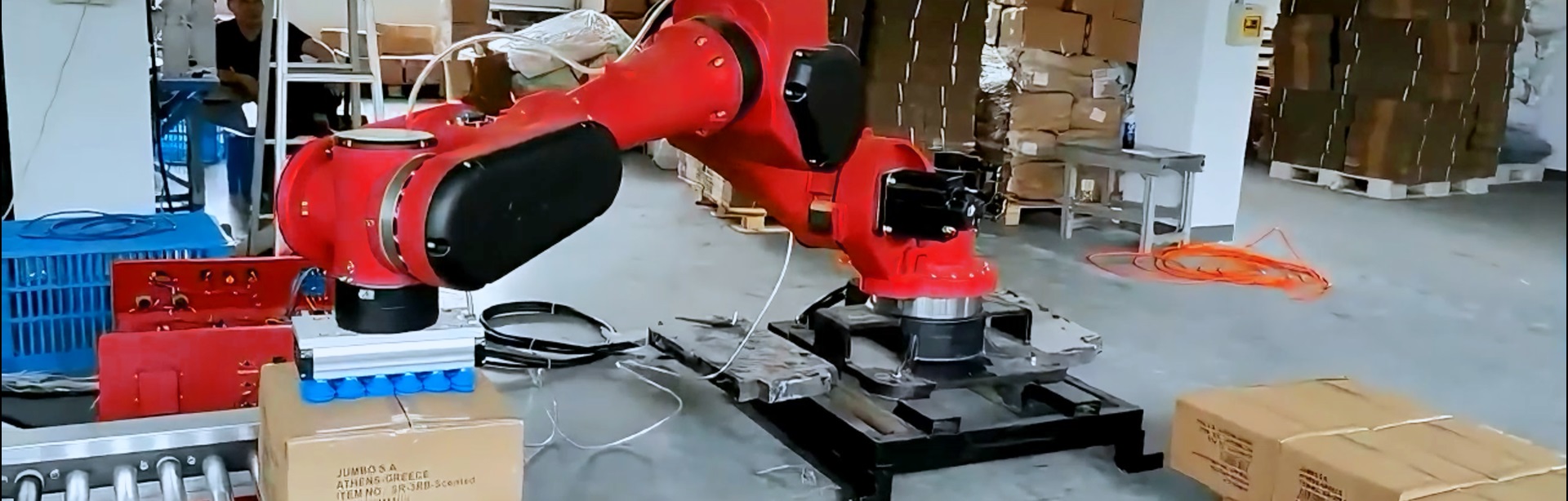

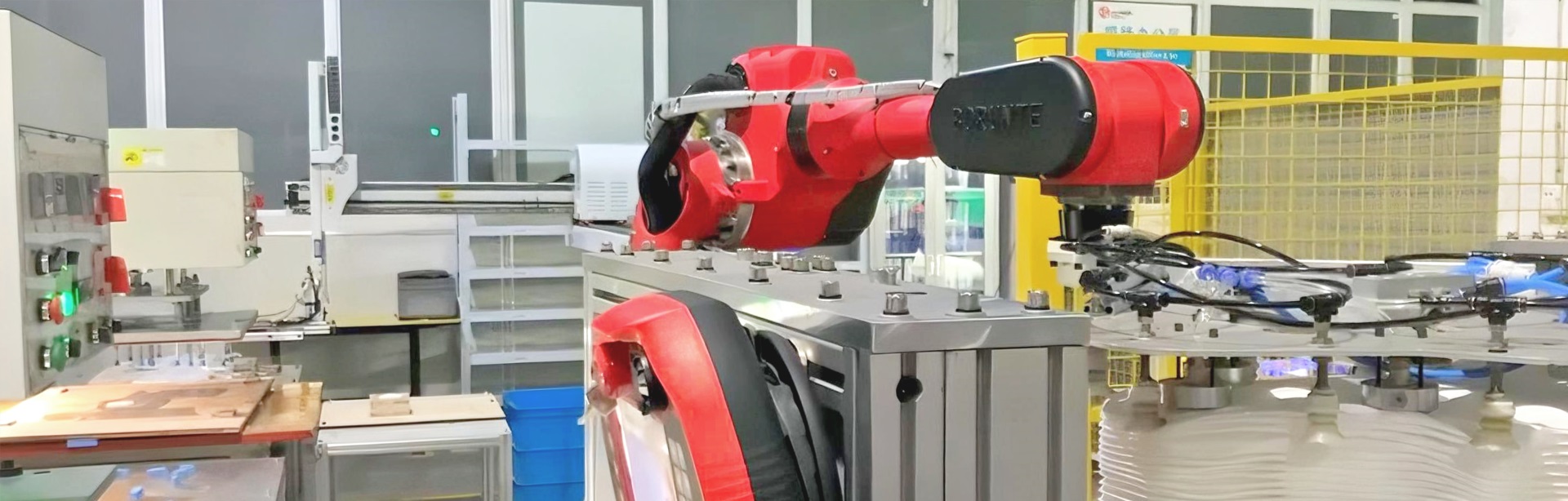

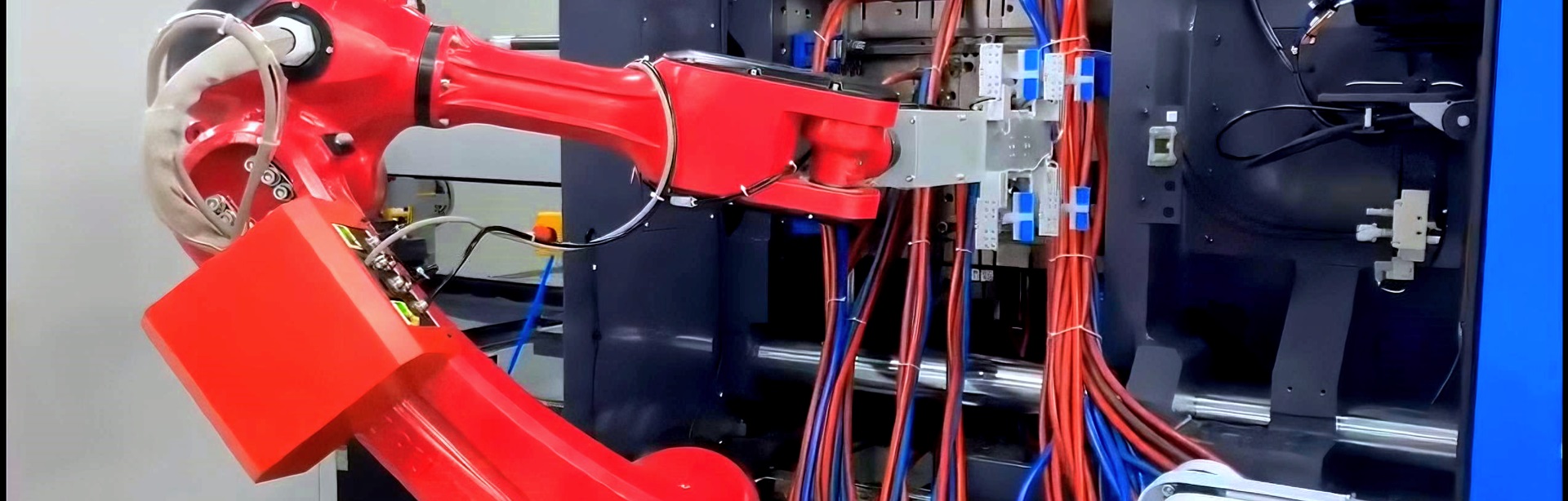

The application of BRTIRUS3030A industrial robot:

1. Metal processing

Metal processing refers to the processing of copper, iron, aluminum and other raw materials into articles, parts and components. It can replace manual forging, rolling, drawing steel wire, impact extrusion, bending, shearing and other processes.

2. Polishing

The pneumatic grinder is operated by the robot, which also performs rough grinding, fine grinding, and polishing on the work piece while automatically changing sandpaper with various grain sizes. Different-sized sandpaper is automatically removed and replaced by the robot. Two stations are present, one for polishing and the other for bringing and taking away work items. Every time the polishing process is conducted, water is used as the medium.

3. Assembling

In this context, robot assembly often refers to vehicle assembly. Automobile assembly is separated into a set of steps on an automated manufacturing line. Engineers establish numerous techniques to collaborate with employees in order to fulfill the installation of doors, front covers, tires, and other components.

Robot handling and hoisting diagram

BRTIRUS3030A Hoisting Standard Description:

1. Two straps of the same length pass through both sides of the base.

2. The left side of sling 1 is fixed at the intersection of the first and second axis rotating seats and the spring cylinder body, passing through the inner side of the boom and facing upwards. The length is slightly shorter to prevent robot from tilting back, and the right side passes through the left side of the second axis motor.

3. The left side of sling 2 is fixed on the second axis of the boom, and the right side passes through the right side of the first axis motor.

4. Remove the fixing screws from the base in the receiving position and secure the lifting strap as described above.

5. Gradually raise the hook and tighten the strap.

6. Gradually raise the hook and observe the tilt of the base when lifted.

7. Lower the hook and adjust the length of the straps 1 and 2 on both sides according to the tilt of the base.

8. Repeat steps 5-7 to ensure that the base remains level when lifted.

9. Move in other directions.

Working conditions of BRTIRUS2030A

1. Power supply: 220V±10% 50HZ±1%

2. Operating temperature: 0℃ ~ 40℃

3. Optimal environmental temperature: 15℃ ~ 25℃

4. Relative humidity: 20-80% RH (No condensation)

5. Mpa: 0.5-0.7Mpa

-

transport

-

stamping

-

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top