Roboto ea mofuta oa BRTIRWD1506A ke roboto ea li-axis tse tšeletseng e ntlafalitsoeng ke BORUNTE bakeng sa nts'etsopele ea indasteri ea li-welding application. Roboto e na le sebopeho se kopaneng, molumo o monyane le boima bo bobebe. Boima bo boholo ke 6kg, bolelele ba letsoho bo boholo ke 1600mm. Letsoho le sebetsa ka mokhoa o se nang letho o nang le mohlala o bonolo haholoanyane le ketso e tenyetsehang. Sehlopha sa tšireletso se fihla ho IP54. E thibelang lerole le ho thibela metsi. Ho nepahala ha boemo bo pheta-phetoang ke ± 0.05mm.

Boemo bo Nepahetseng

Ka potlako

Bophelo bo Bolelele ba Tšebeletso

Sekhahla sa ho hloleha ho tlase

Fokotsa Mosebetsi

Mohala oa puisano

| Ntho | Range | Lebelo le phahameng | ||

| Letsoho | J1 | ±165° | 163°/s | |

| J2 | -100°/+70° | 149°/s | ||

| J3 | ±80° | 223°/s | ||

| Letsoho | J4 | ±150° | 169°/s | |

| J5 | ±110° | 270°/s | ||

| J6 | ± 360° | 398°/s | ||

|

| ||||

| Bolelele ba Letsoho (mm) | Loading Ability (kg) | Ho nepahala ha Maemo a Phethahetseng (mm) | Mohloli oa Matla (kVA) | Boima (kg) |

| 1600 | 6 | ±0.05 | 4.64 | 166 |

Likarolo tsa bohlokoa tsa ho sebelisa roboto ea welding:

1. Tsitsisa le ho ntlafatsa boleng ba welding ho netefatsa ho ts'oana ha eona.

U sebelisa roboto ea ho tjheseletsa, litekanyo tsa welding bakeng sa weld e 'ngoe le e' ngoe li lula li le teng, 'me boleng ba weld ha bo amehe haholo ke lintlha tsa batho, bo fokotsa litlhoko tsa litsebo tsa ho sebetsa tsa basebetsi, kahoo boleng ba welding bo tsitsitse.

2. Ntlafatsa tlhahiso.

Roboto e ka hlahisoa khafetsa lihora tse 24 ka letsatsi. Ho feta moo, ka ts'ebeliso ea theknoloji ea welding e potlakileng le e sebetsang hantle, ts'ebetso ea ho tjheseletsa ha Robot e ntlafatsoa haholo.

3. Hlakola potoloho ea sehlahisoa, ho le bonolo ho laola tlhahiso ea lihlahisoa.

Moralo oa tlhahiso ea liroboto o tsitsitse, kahoo moralo oa tlhahiso o hlakile haholo.

4. khutsufatsa potoloho ea phetoho ea lihlahisoa

E ka fihlella li-welding automation bakeng sa lihlahisoa tse nyane tsa batch. Phapang e kholo ka ho fetisisa pakeng tsa roboto le mochine o khethehileng ke hore o khona ho ikamahanya le tlhahiso ea lisebelisoa tse fapaneng tsa mosebetsi ka ho fetola lenaneo.

-

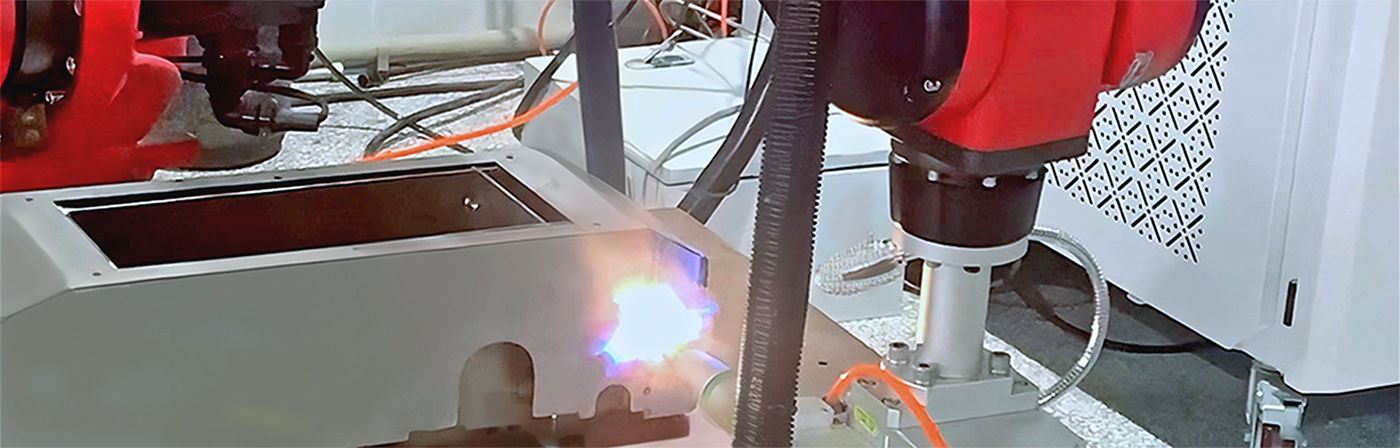

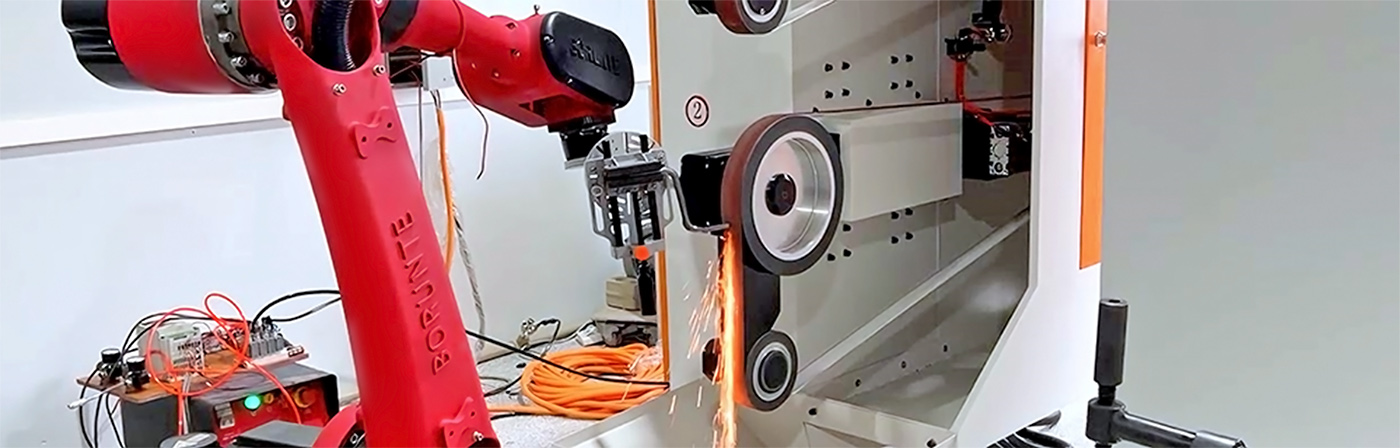

Ho tjheseletsa letheba

-

Ho chesoa ka laser

-

Ho benya

-

Ho poma

Lihlopha tsa lihlahisoa

BORUNTE le BORUNTE integrators

Setsing sa tikoloho ea BORUNTE, BORUNTE e ikarabella bakeng sa R&D, tlhahiso, le thekiso ea liroboto le li-manipulator. Bahokahanyi ba BORUNTE ba sebelisa indasteri ea bona kapa melemo ea masimong ho fana ka moralo oa ts'ebeliso ea terminal, kopanyo, le ts'ebeletso ea kamora thekiso bakeng sa lihlahisoa tsa BORUNTE tseo ba li rekisang. Bahoebi ba BORUNTE le BORUNTE ba phethahatsa boikarabelo ba bona 'me ba ikemetse ho e mong, ba sebetsa hammoho ho ntšetsa pele bokamoso bo khanyang ba BORUNTE.

-

-

-

-

Holimo