Roboto ea mofuta oa BRTIRWD1606A ke roboto ea li-axis tse tšeletseng e ntlafalitsoeng ke BORUNTE bakeng sa indasteri ea li-welding. Roboto ena e na le sebōpeho se kopaneng, e nyenyane ka boholo le boima bo bobebe. Boima ba eona bo boholo ke 6kg mme bolelele ba letsoho la eona ke 1600mm. Sebopeho se sekoti sa letsoho, mohala o bonolo haholoanyane, ketso e tenyetsehang haholoanyane. Manonyeletso a pele, a bobeli le a boraro a na le lisebelisoa tse fokolang tse phahameng haholo, 'me motsoako oa bone, oa bohlano le oa botšelela o na le lisebelisoa tse nang le lisebelisoa tse phahameng tsa lisebelisoa, kahoo lebelo le phahameng le kopantsoeng le ka etsa mesebetsi e feto-fetohang. Boemo ba tšireletso bo fihla ho IP54. E thibelang lerole le ho thibela metsi. Ho nepahala ha boemo bo pheta-phetoang ke ± 0.05mm.

Boemo bo Nepahetseng

Ka potlako

Bophelo bo Bolelele ba Tšebeletso

Sekhahla sa ho hloleha ho tlase

Fokotsa Mosebetsi

Mohala oa puisano

| Ntho | Range | Lebelo le phahameng | ||

| Letsoho | J1 | ±165° | 158°/s | |

| J2 | -95°/+70° | 143°/s | ||

| J3 | ±80° | 228°/s | ||

| Letsoho | J4 | ±155° | 342°/s | |

| J5 | -130°/+120° | 300°/s | ||

| J6 | ± 360° | 504°/s | ||

|

| ||||

| Bolelele ba Letsoho (mm) | Loading Ability (kg) | Ho nepahala ha Maemo a Phethahetseng (mm) | Mohloli oa Matla (kVA) | Boima (kg) |

| 1600 | 6 | ±0.05 | 6.11 | 157 |

U ka khetha liroboto tsa welding tsa indasteri joang?

1. Tseba mokhoa oa ho cheselletsa tjheseletso: Etsa qeto ya hore na o tla sebedisa tjheseletso efe, e kang MIG, TIG, kapa welding. Mekhoa e fapaneng e ka hloka mefuta e fapaneng ea lisebelisoa.

2. Utloisisa litlhaloso tsa karolo ea mosebetsi: Sekaseka boholo, sebōpeho, le thepa ea karolo ea mosebetsi e lokelang ho chesetsoa. Sesebelisoa se tlameha ho amohela le ho ts'oara karolo ea mosebetsi ka mokhoa o sireletsehileng nakong ea welding.

3. Nahana ka mefuta ea tšubuhlellano ea ho tjheseletsa: Lekola mefuta ea manonyeletso (mohlala, lenonyeletso la butt, lap joint, corner joint) o tla be o tjheseletsa, kaha sena se tla ama moralo le tlhophiso ea sebopeho.

4. Hlahloba bophahamo ba tlhahiso: Nahana ka bophahamo ba tlhahiso le hore na mochine o tla sebelisoa hangata hakae. Bakeng sa tlhahiso ea molumo o phahameng, ho ka hlokahala hore ho be le ntho e tšoarellang haholoanyane le e ikemetseng.

5. Lekola litlhoko tsa ho nepahala ha tjheseletsa: Etsa qeto ea boemo ba ho nepahala bo hlokahalang bakeng sa morero oa welding. Lisebelisoa tse ling li ka hloka mamello e matla, e tla susumetsa moralo le kaho ea sesebelisoa.

Setšoantšo se akaretsang sa BRTIRWD1606A

BRTIRWD1606A e amohela sebopeho sa liroboto tse kopaneng tsa li-axis tse tšeletseng, li-servo motors tse tšeletseng li khanna ho potoloha ha lilepe tse tšeletseng tse kopaneng ka li-reducers le likere. E na le likhato tse tšeletseng tsa tokoloho, e leng ho potoloha (X), letsoho le ka tlaase (Y), letsoho le ka holimo (Z), ho bilika ha letsoho (U), ho sotheha ha letsoho (V), le ho bilika ha letsoho (W).

BRTIRWD1606A lenonyeletso la 'mele le entsoe ka aluminiamo e entsoeng ka tšepe kapa tšepe e entsoeng ka tšepe, e netefatsang matla a holimo, lebelo, ho nepahala le botsitso ba roboto.

-

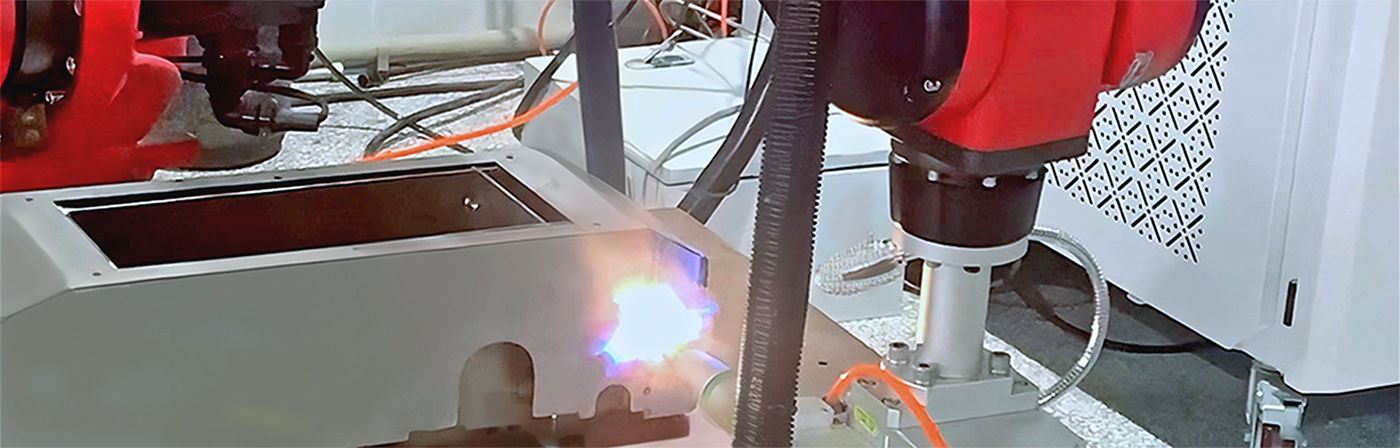

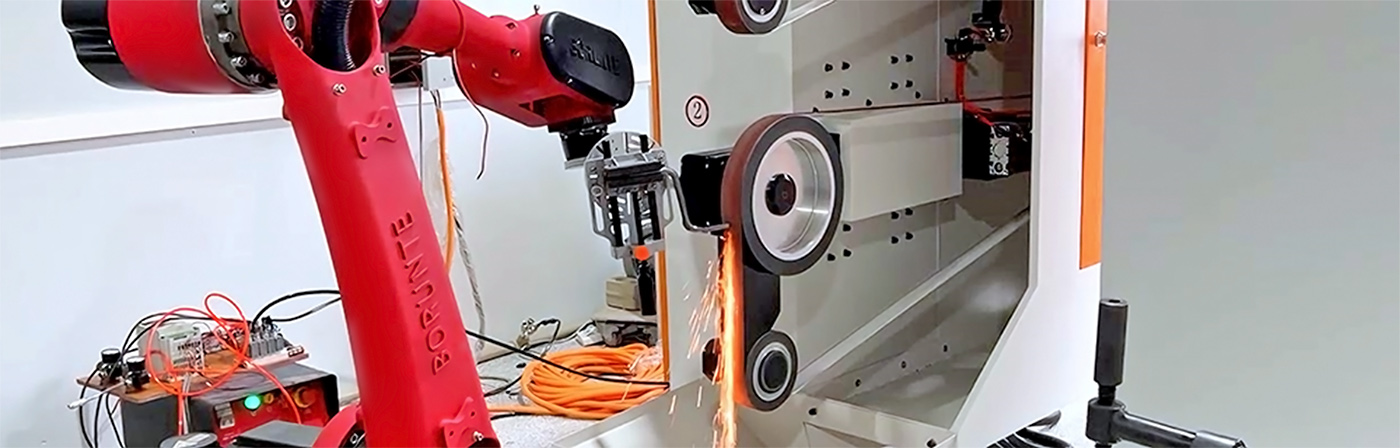

Ho tjheseletsa letheba

-

Ho chesoa ka laser

-

Ho benya

-

Ho poma

Lihlopha tsa lihlahisoa

BORUNTE le BORUNTE integrators

Setsing sa tikoloho ea BORUNTE, BORUNTE e ikarabella bakeng sa R&D, tlhahiso, le thekiso ea liroboto le li-manipulator. Bahokahanyi ba BORUNTE ba sebelisa indasteri ea bona kapa melemo ea masimong ho fana ka moralo oa ts'ebeliso ea terminal, kopanyo, le ts'ebeletso ea kamora thekiso bakeng sa lihlahisoa tsa BORUNTE tseo ba li rekisang. Bahoebi ba BORUNTE le BORUNTE ba phethahatsa boikarabelo ba bona 'me ba ikemetse ho e mong, ba sebetsa hammoho ho ntšetsa pele bokamoso bo khanyang ba BORUNTE.

-

-

-

-

Holimo