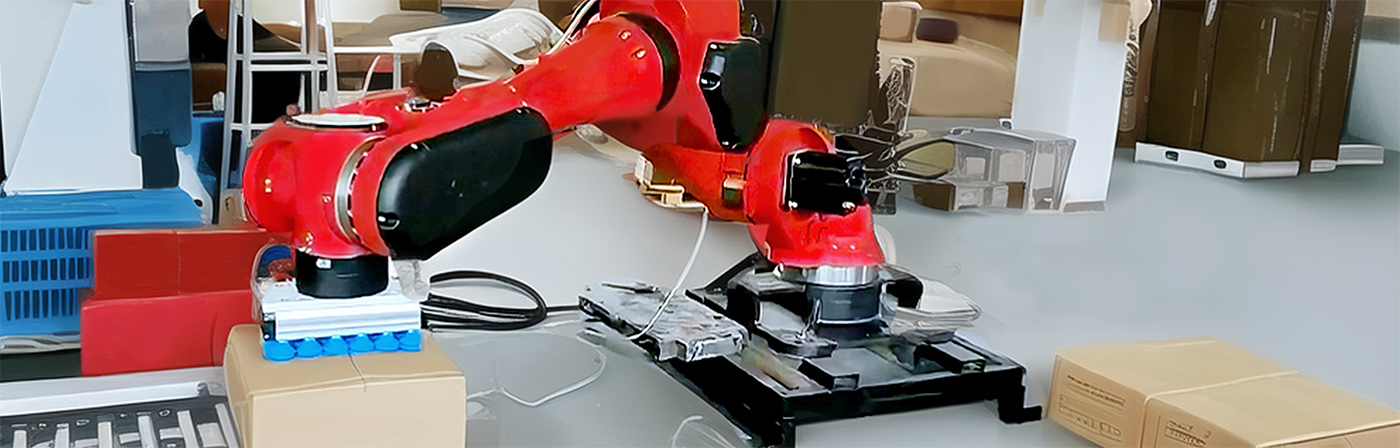

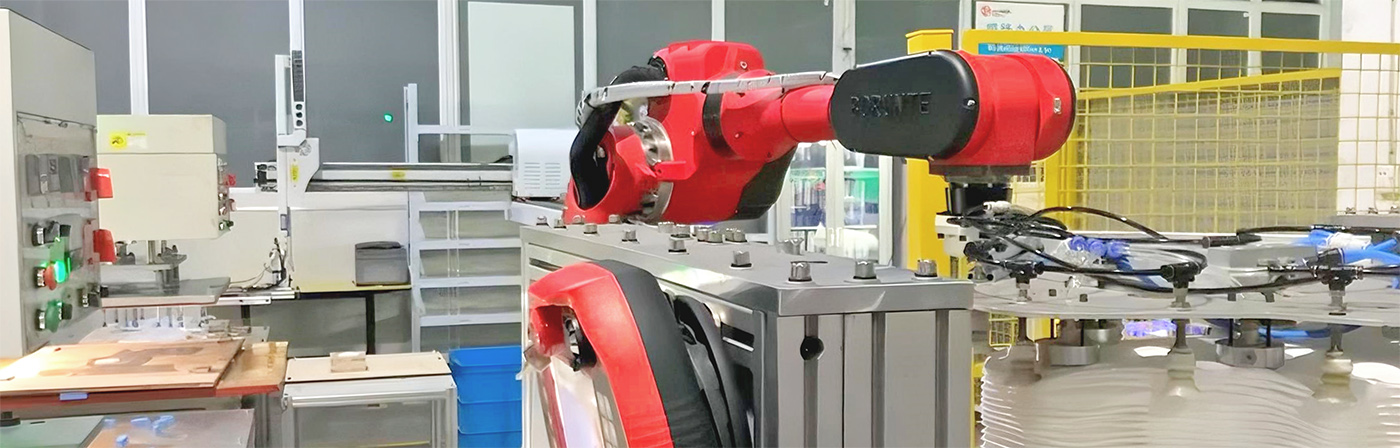

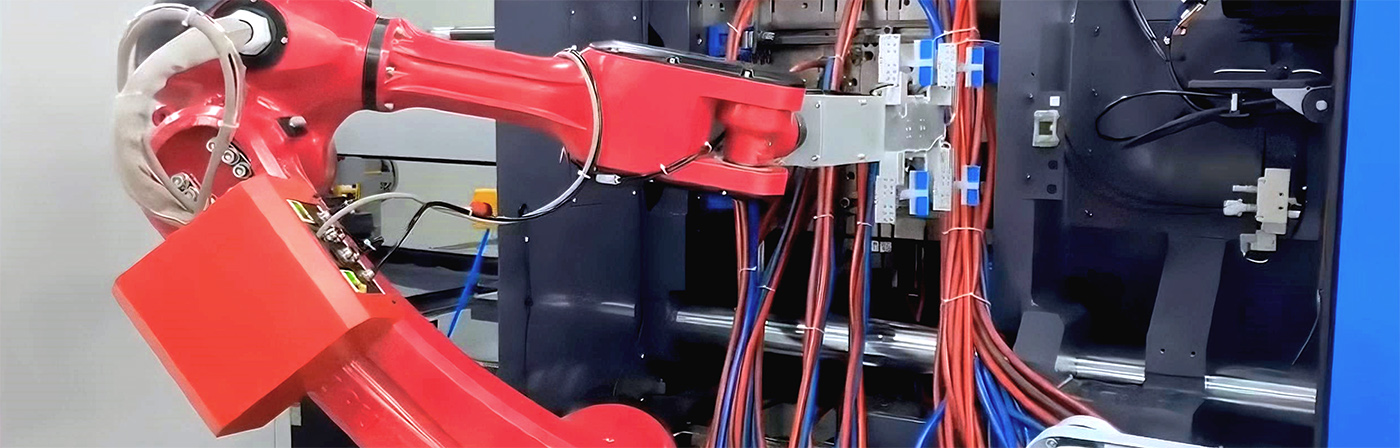

Roboto ea mofuta oa BRTIRPZ1508A ke roboto e nang le li-axis tse 'ne e ntlafalitsoeng ke BORUNTE, e sebelisa koloi e felletseng ea servo ka karabelo e potlakileng le ho nepahala ha maemo a holimo. Boima bo boholo ke 8kg, bolelele ba letsoho bo boholo ke 1500mm. Sebopeho sa Compact se finyella mefuta e mengata ea ho sisinyeha, lipapali tse feto-fetohang, tse nepahetseng. E loketse libaka tse kotsi le tse thata, tse kang ho hatakela, ho laola khatello, phekolo ea mocheso, ho penta, ho bōpa polasetiki, ho sebetsa ka mechine le mekhoa e bonolo ea kopano. Le indastering ea matla a athomo, ho phethela ts'ebetso ea lisebelisoa tse kotsi le tse ling. E loketse ho phunya. Boemo ba tšireletso bo fihla ho IP40. Ho nepahala ha boemo bo pheta-phetoang ke ± 0.05mm.

Boemo bo Nepahetseng

Ka potlako

Bophelo bo Bolelele ba Tšebeletso

Sekhahla sa ho hloleha ho tlase

Fokotsa Mosebetsi

Mohala oa puisano

| Ntho | Range | Lebelo le phahameng | ||

| Letsoho | J1 | ±160° | 219.8°/s | |

| J2 | -70°/+23° | 222.2°/s | ||

| J3 | -70°/+30° | 272.7°/s | ||

| Letsoho | J4 | ± 360° | 412.5°/s | |

| R34 | 60°-165° | / | ||

|

| ||||

| Bolelele ba Letsoho (mm) | Loading Ability (kg) | Ho nepahala ha Maemo a Phethahetseng (mm) | Mohloli oa Matla (kVA) | Boima (kg) |

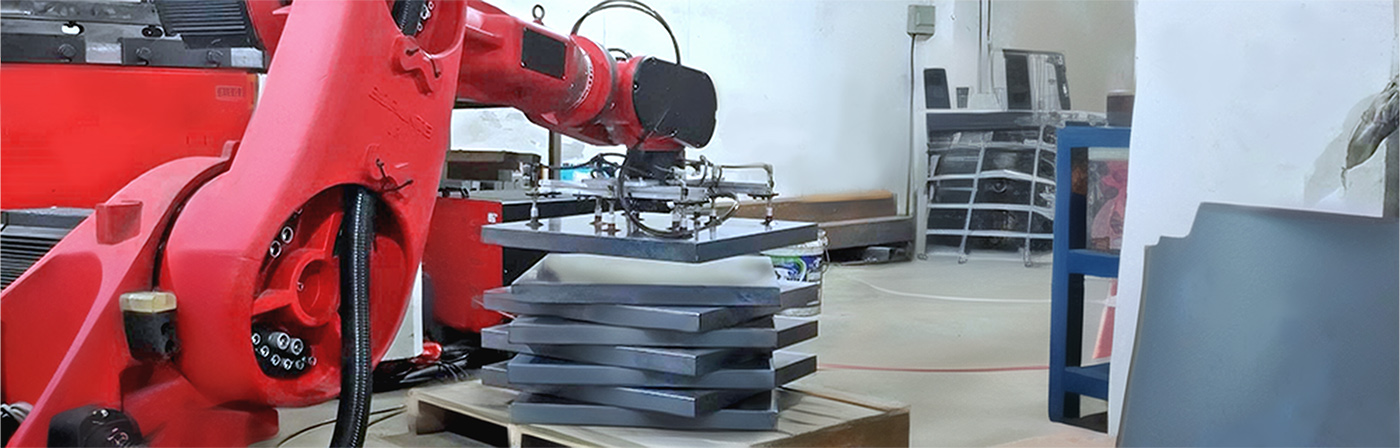

| 1500 | 8 | ±0.05 | 3.18 | 150  1.Roboto e nang le li-axis tse nne ke eng? Roboto ea li-axis tse nne ke mofuta oa liroboto tsa indasteri tse nang le likhato tse 'ne tsa tokoloho tse etselitsoeng ka ho khetheha mesebetsi e amanang le ho bokella, ho hlophisa, kapa ho beha lintho ka har'a lits'ebetso tse fapaneng tsa indasteri. 2. Melemo ea ho sebelisa roboto e nang le li-axis tse 'nè ke efe? Liroboto tse nang le li-axis tse 'nè li fana ka ts'ebetso e eketsehileng, ho nepahala, le ho tsitsisa mesebetsing ea ho bokella le ho bokella. Ba khona ho sebetsana le meroalo e mengata e fapaneng mme ba hlophisehile ho etsa lipaterone tse rarahaneng tsa stacking. 3. Ke mefuta efe ea likopo tse loketseng roboto e nang le li-axis tse 'nè? Liroboto tsena li sebelisoa hangata liindastering tse joalo ka tlhahiso, thepa, lijo le lino, le thepa ea bareki bakeng sa mesebetsi e kang mabokose a ho paka, mekotla, mabokose le lintho tse ling. 4. Ke khetha roboto e nepahetseng ea li-axis tse 'nè joang bakeng sa litlhoko tsa ka? Nahana ka lintlha tse kang bokhoni ba ho lefa, phihlello, lebelo, ho nepahala, sebaka sa mosebetsi se fumanehang, le mefuta ea lintho tseo u hlokang ho li bokella. Etsa tlhahlobo e phethahetseng ea litlhoko tsa hau tsa kopo pele u khetha mofuta o itseng.  1. Sebelisa stacking, kenya palletizing parameters. ● Kenya taelo ea ts'ebetso, ho na le litaelo tse 4: ntlha ea phetoho, e loketse ho sebetsa, sebaka sa stacking, 'me u tlohe ntlha. Ka kopo sheba tlhaloso ea litaelo bakeng sa lintlha.  1. Ho tlameha ho ba le liparamente tsa "palletizing stack" lenaneong la hajoale.

Lihlopha tsa lihlahisoaBORUNTE le BORUNTE integratorsSetsing sa tikoloho ea BORUNTE, BORUNTE e ikarabella bakeng sa R&D, tlhahiso, le thekiso ea liroboto le li-manipulator. Bahokahanyi ba BORUNTE ba sebelisa indasteri ea bona kapa melemo ea masimong ho fana ka moralo oa ts'ebeliso ea terminal, kopanyo, le ts'ebeletso ea kamora thekiso bakeng sa lihlahisoa tsa BORUNTE tseo ba li rekisang. Bahoebi ba BORUNTE le BORUNTE ba phethahatsa boikarabelo ba bona 'me ba ikemetse ho e mong, ba sebetsa hammoho ho ntšetsa pele bokamoso bo khanyang ba BORUNTE.

|