Roboto ea mofuta oa BRTIRSC0810A ke roboto ea li-axis tse 'ne e ntlafalitsoeng ke BORUNTE bakeng sa ts'ebetso ea nako e telele e monate, khafetsa le e pheta-phetoang. Bolelele ba letsoho bo phahameng ke 800mm. Boima bo boholo ke 10kg. E feto-fetoha le maemo a mangata a tokoloho. E loketse ho hatisa le ho paka, ho sebetsa litšepe, thepa ea ka tlung ea masela, lisebelisoa tsa elektroniki, le mafapha a mang. Boemo ba tšireletso bo fihla ho IP40. Ho nepahala ha boemo bo pheta-phetoang ke ± 0.03mm.

Boemo bo Nepahetseng

Ka potlako

Bophelo bo Bolelele ba Tšebeletso

Sekhahla sa ho hloleha ho tlase

Fokotsa Mosebetsi

Mohala oa puisano

| Ntho | Range | Lebelo le phahameng | ||

| Letsoho | J1 | ±130° | 300°/s | |

| J2 | ±140° | 473.5°/s | ||

| J3 | 180 limilimithara | 1134mm/s | ||

| Letsoho | J4 | ± 360° | 1875°/s | |

|

| ||||

| Bolelele ba Letsoho (mm) | Loading Ability (kg) | Ho nepahala ha Maemo a Phethahetseng (mm) | Mohloli oa Matla (kVA) | Boima (kg) |

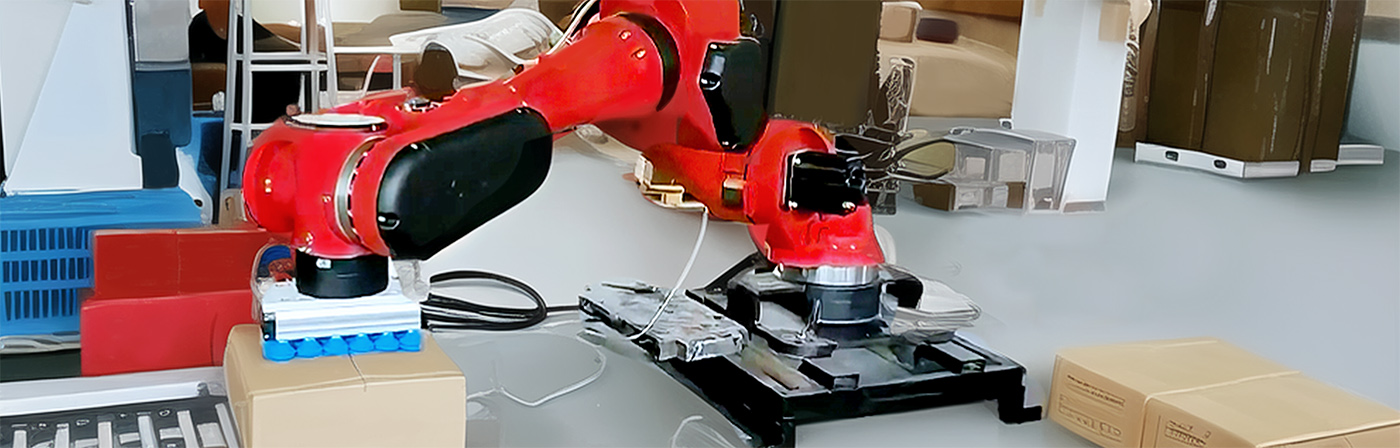

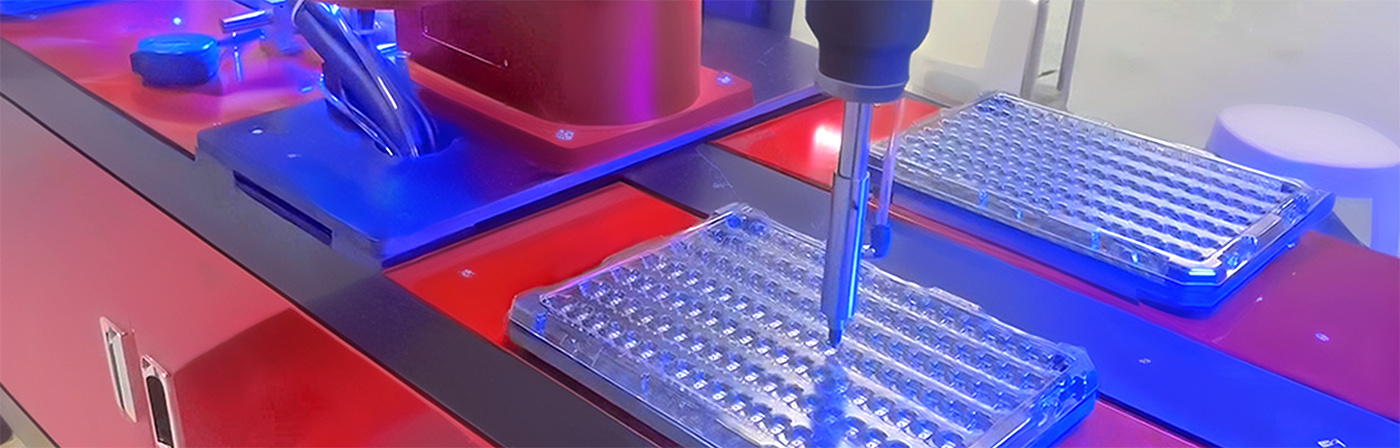

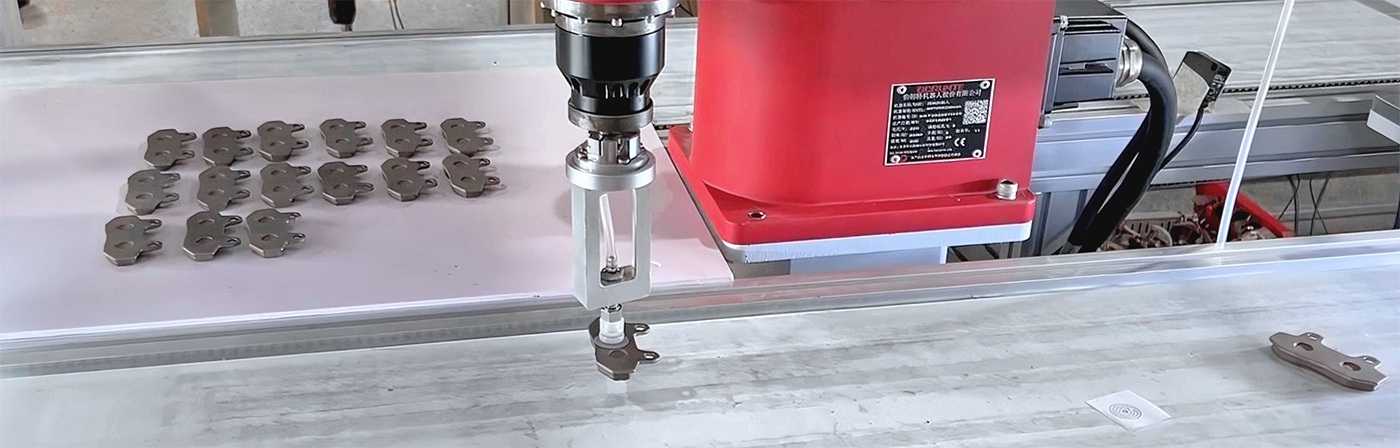

| 800 | 10 | ±0.03 | 4.30 | 75  1.Pick and Place Operations: Roboto ea SCARA e nang le li-axis tse 'nè e atisa ho sebelisoa bakeng sa ts'ebetso ea ho khetha le ho beha sebakeng sa ho etsa le ho kopanya. E ipabola tabeng ea ho nka lintho sebakeng se seng le ho li beha ka nepo sebakeng se seng. Mohlala, tlhahisong ea lisebelisoa tsa elektroniki, roboto ea SCORA e ka khetha likarolo tsa elektroniki ho tsoa litereing kapa meqomong ebe e li beha holim'a liboto tsa potoloho ka nepo e phahameng. Lebelo la eona le ho nepahala ha eona li etsa hore e tšoanelehe bakeng sa libaka tse phahameng tsa tlhahiso. 2.Tlhahiso le Pakete ea Material: Liroboto tsa SCORA li sebelisoa mesebetsing ea ho sebetsana le thepa le ho paka, joalo ka ho hlophisa, ho paka, le ho paka lihlahisoa. Setsing sa ho lokisa lijo, roboto e ne e ka nka lijo lebantang la conveyor ebe li li kenya ka har'a literei kapa mabokoseng, ho netefatsa tlhophiso e tsitsitseng le ho fokotsa tšenyo ea sehlahisoa. Roboto ea SCARA e ipheta-pheta le bokhoni ba ho sebetsana le lintho tse fapaneng e etsa hore e be e loketseng lits'ebetso tsena. 3.Assembly and Fastening: Liroboto tsa SCORA li sebelisoa haholo mekhoeng ea likopano, haholo-holo tse amanang le likaroloana tse nyenyane ho isa ho tse mahareng. Ba ka etsa mesebetsi e kang screwing, bolting, le ho kopanya likarolo hammoho. Mohlala, indastering ea likoloi, roboto ea SCARA e ka kopanya likarolo tse fapaneng tsa enjene ka ho tiisa liboutu le ho boloka likarolo ka tatellano e boletsoeng esale pele. Ho nepahala le lebelo la roboto li kenya letsoho ho ntlafatseng boleng ba sehlahisoa le katlehong ea tlhahiso. 4.Tlhahlobo ea Boleng le Teko: Liroboto tsa SCORA li bapala karolo ea bohlokoa tlhahlobong ea boleng le lits'ebetsong tsa tlhahlobo. Li ka hlomelloa ka lik'hamera, li-sensor, le lisebelisoa tsa ho lekanya ho lekola lihlahisoa bakeng sa mefokolo, ho etsa litekanyo, le ho netefatsa hore li latela litlhaloso. Metsamao e tsitsitseng le e phetoang ea roboto e matlafatsa ts'epahalo ea lits'ebetso tsa tlhahlobo. 1. ho nepahala le lebelo le phahameng: ho sebelisoa motlakase oa servo le mochine o fokotsang boemo bo phahameng, karabelo e potlakileng le ho nepahala ho phahameng.

Lihlopha tsa lihlahisoaBORUNTE le BORUNTE integratorsSetsing sa tikoloho ea BORUNTE, BORUNTE e ikarabella bakeng sa R&D, tlhahiso, le thekiso ea liroboto le li-manipulator. Bahokahanyi ba BORUNTE ba sebelisa indasteri ea bona kapa melemo ea masimong ho fana ka moralo oa ts'ebeliso ea terminal, kopanyo, le ts'ebeletso ea kamora thekiso bakeng sa lihlahisoa tsa BORUNTE tseo ba li rekisang. Bahoebi ba BORUNTE le BORUNTE ba phethahatsa boikarabelo ba bona 'me ba ikemetse ho e mong, ba sebetsa hammoho ho ntšetsa pele bokamoso bo khanyang ba BORUNTE.

|