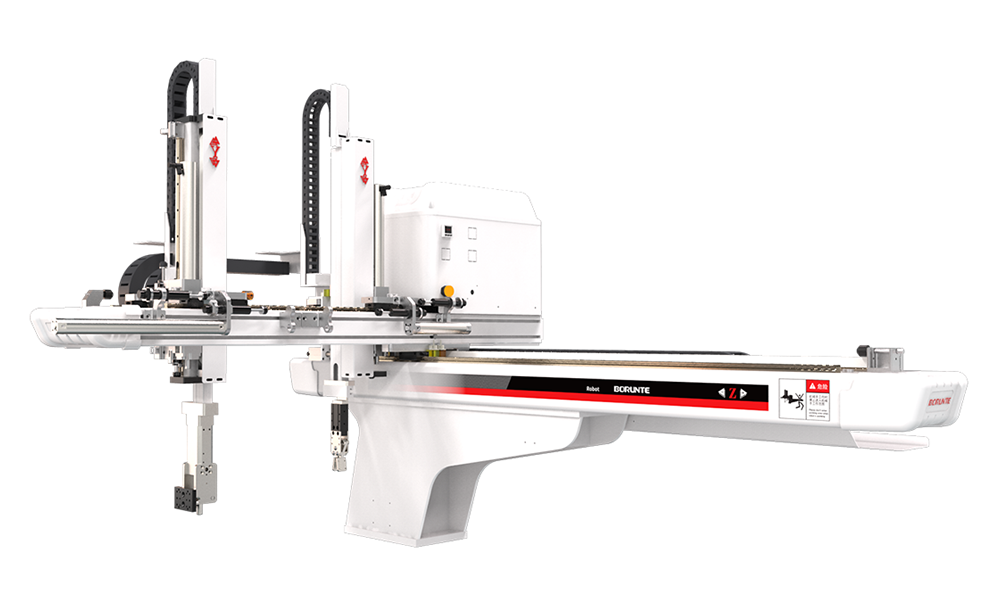

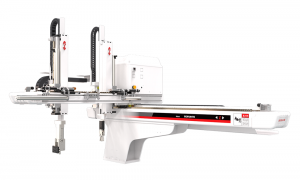

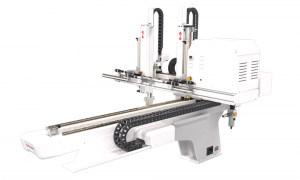

BRTB06WDS1P0/F0 gacanta Robot-ku-socod waxay khusaysaa dhammaan noocyada kala duwan ee mishiinnada duritaanka jiifka ah ee 30T-120T ee alaabta la soo saarayo iyo sprue. Gacanta toosan waa nooca telescopic, oo leh cudud wax soo saar iyo cudud orodyahan, laba saxan ama saddex saxan oo caaryar ah ayaa la soo baxay. dhidibka goosashada waxaa wada matoorka servo AC. Meelaynta saxda ah, xawaaraha degdega ah, cimri dheer, iyo heerka guuldarada hoose. Ku rakibidda manipulator-ka, wax-soo-saarka ayaa la kordhin doonaa 10-30% wuxuuna hoos u dhigi doonaa heerka cilladaysan ee alaabta, hubinta badbaadada hawl-wadeennada, hoos u dhigista xoogga shaqaalaha iyo si sax ah u xakameynaya wax soo saarka si loo yareeyo qashinka.

Meelaynta saxda ah

Degdeg ah

Nolosha Adeegga Dheer

Heerka Fashilka Hoose

Yaraynta Foosha

Isgaarsiinta

| Isha Korontada (KVA) | IMM (ton) lagu taliyay | Waddada loo wado | Tusmada ugu hooseysa ee EOAT |

| 1.69 | 30T-120T | AC Servo motor | hal nuugid hal qalab |

| Stroke Traverse (mm) | Istaroog ka gudubta (mm) | Faalig toosan (mm) | Ugu badnaan rarista (kg) |

| 1100 | P: 200-R: 125 | 600 | 3 |

| Waqti qallalan | Wakhtiga Wareegga Qalalan (second) | Isticmaalka Hawada (NI/wareegga) | Miisaanka (kg) |

| 1.6 | 5.8 | 3.5 | 175 |

Tusaalaha qaabka: W: Nooca telescopic. D: Cududda alaabta + cudud orodyahan. S5: Shan geesood oo ay wado AC Servo Motor

Waqtiga wareegga ee kor lagu soo sheegay waa natiijooyinka heerka imtixaanka gudaha ee shirkadeena. Habka codsiga dhabta ah ee mashiinka, waxay ku kala duwanaan doonaan sida hawlgalka dhabta ah.

| A | B | C | D | E | F | G | H |

| 1200 | 1900kii | 600 | 403 | 1100 | 355 | 165 | 210 |

| I | J | K | L | M | N | O | |

| 110 | 475 | 365 | 1000 | 242 | 365 | 933 |

Ogeysiis dambe ma jiro haddii qeexitaanka iyo muuqaalka la beddelo horumar iyo sababo kale awgeed. Waad ku mahadsan tahay fahamkaaga.

Sidee loogu beddelaa habka gacanta oo loo isticmaalo?

Geli shaashadda gacanta, waxaad samayn kartaa hawlgalka gacanta, ku shaqay manipulator-ka si uu ugu shaqeeyo hal fal kasta, oo aad hagaajiso qayb kasta oo mishiinka ah (marka gacanta lagu shaqeeyo, xaqiiji in ay jirto calaamad lagu furayo caaryada ka hor intaadan sii wadin, oo hubi in caaryada lama taaban). Si loo hubiyo badbaadada manipulators iyo caaryada mishiinka wax-qaabeeya, waxaa jira xayiraadaha soo socda:

Ka dib marka uu robotku soo dego, ma samayn karo dhaqdhaqaaq toosan ama toosan.

Ka dib marka uu robotku soo dego, ma samayn karo dhaqdhaqaaq toosan. (marka laga reebo gudaha aagga badbaadada ee moodeelka) .

Haddii aysan jirin calaamad u furan caaryada, manipulator-ku ma samayn karo dhaqdhaqaaqa hoose ee caaryada.

Dayactirka badbaadada (Xusuusin):

Kahor intaadan dayactirin qalabeeyaha, shaqaalaha dayactirka fadlan si faahfaahsan u akhri waxyaabaha soo socda ee badbaadada si aad uga fogaato khatarta.

1.Fadlan dami korontada ka hor inta aanad hubin mishiinka duritaanka.

2.Kahor hagaajinta iyo dayactirka, fadlan dami qalabka korontada iyo cadaadiska haraaga mashiinka duritaanka iyo manipulator.

3.Marka lagu daro beddelka dhow, nuugista liidata, cillad la'aanta solenoid waa la hagaajin karaa iyaga, kuwa kale waa inay noqdaan shaqaale xirfad leh oo loo tababaray si ay u hagaajiyaan, haddii kale ha isbeddelin fasax la'aan.

4. Fadlan ha beddelin ama ha beddelin qaybaha asalka ah.

5. Inta lagu jiro hagaajinta caaryada ama isbeddelka, fadlan fiiro gaar ah u yeelo badbaadada si aad uga fogaato in uu dhaawaco manipulator-ka.

6.Ka dib hagaajinta ama hagaajinta manipulator-ka, fadlan ka tag goobta shaqada ee khatarta ah ka hor inta aanad shaqada gelin.

7.Ha shidin korantada ama ha ku xidhin kombastarka hawada gacanta farsamada.

-

qaabaynta cirbada

Qaybaha alaabta

BORUNTE iyo BORUNTE integrators

Nidaamka deegaanka ee BORUNTE, BORUNTE waxay mas'uul ka tahay R&D, wax soo saarka, iyo iibinta robots-yada iyo wax-is-beddelayaasha. Isku-dhafka BORUNTE waxay ka faa'iidaystaan warshadooda ama faa'iidooyinka goobta si ay u bixiyaan naqshadaynta codsiga, isdhexgalka, iyo adeegga iibka ka dib ee alaabta BORUNTE ee ay iibiyaan. Isku-dhafka BORUNTE iyo BORUNTE waxay gutaan waajibaadkooda shaqo, waxayna ka madax bannaan yihiin midba midka kale, iyagoo ka wada shaqeynaya horumarinta mustaqbalka ifaya ee BORUNTE.

-

-

-

-

Sare