BRTIRWD1506A robhoti remhando yerobhoti matanhatu-axis rakagadzirwa neBORUNTE kuitira kusimudzira indasitiri yewelding application. Iyo robhoti ine compact chimiro, vhoriyamu diki uye huremu huremu. Mutoro mukuru ndeye 6kg, kureba kweruoko i1600mm. Iyo wrist inoshandisa hollow chimiro chine nyore nyore kutsvaga uye inochinjika chiito. Giredhi rekudzivirira rinosvika IP54. Kudzivirira guruva uye kusapinda kwemvura. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.05mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±165° | 163°/s | |

| J2 | -100°/+70° | 149°/s | ||

| J3 | ±80° | 223°/s | ||

| Wrist | J4 | ±150° | 169°/s | |

| J5 | ±110° | 270°/s | ||

| J6 | ±360° | 398°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 1600 | 6 | ±0.05 | 4.64 | 166 |

Zvinokosha zvekushandisa robhoti welding:

1. Gadzirisa uye uvandudze welding mhando kuti ive nechokwadi chekufanana kwayo.

Uchishandisa Robot welding, iyo welding parameters yeweld yega yega inogara, uye weld mhando haina kukanganiswa nezvinhu zvevanhu, inoderedza zvinodiwa zvehunyanzvi hwekushanda kwevashandi, saka welding mhando yakagadzikana.

2. Kuvandudza zvibereko.

Iyo robhoti inogona kuramba ichigadzirwa maawa makumi maviri nemana pazuva. Uye zvakare, nekushandiswa kweyepamusoro-kumhanya uye inobudirira welding tekinoroji, kugona kweRobot welding welding inovandudzwa zvakanyanya.

3. Bvisa chigadzirwa kutenderera, nyore kudzora chigadzirwa chinobuda.

Iyo rhythm yekugadzira yemarobhoti yakagadziriswa, saka chirongwa chekugadzira chakajeka kwazvo.

4.Kupfupisa kutenderera kwechigadzirwa shanduko

Inogona kuwana welding otomatiki kune zvidiki batch zvigadzirwa. Musiyano mukuru pakati perobhoti nemuchina wakasarudzika ndewekuti unogona kuenderana nekugadzirwa kweakasiyana maworkpiece nekugadzirisa chirongwa.

-

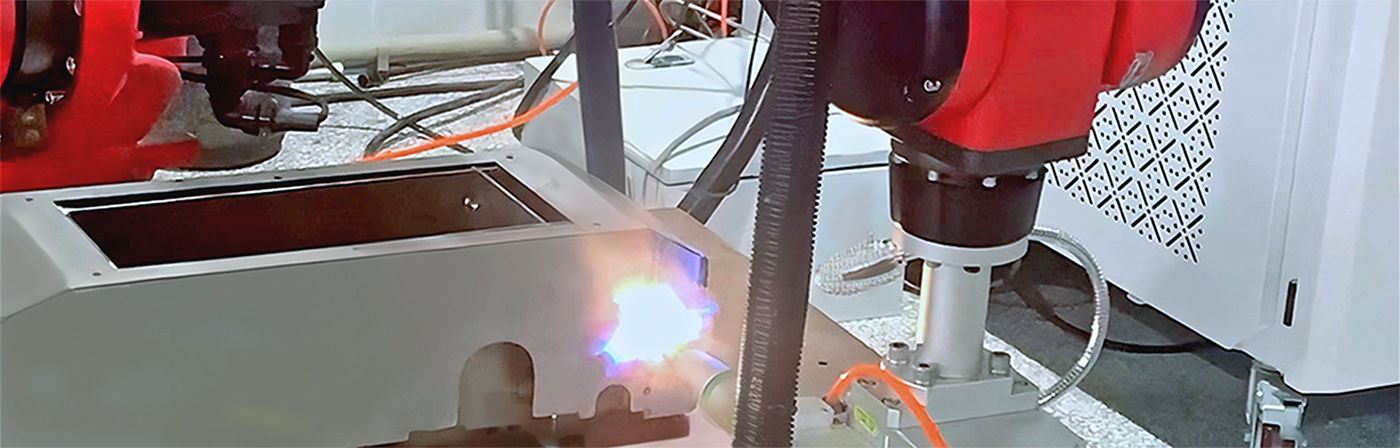

Spot welding

-

Laser welding

-

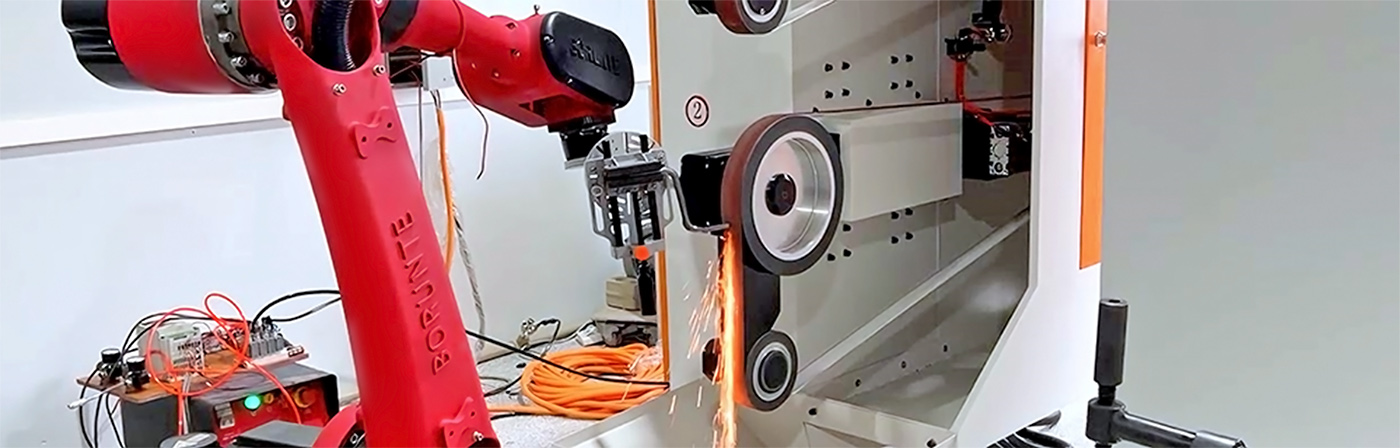

Kupukuta

-

Kucheka

Zvigadzirwa zvikamu

BORUNTE uye BORUNTE vanobatanidza

MuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

-

-

-

Top