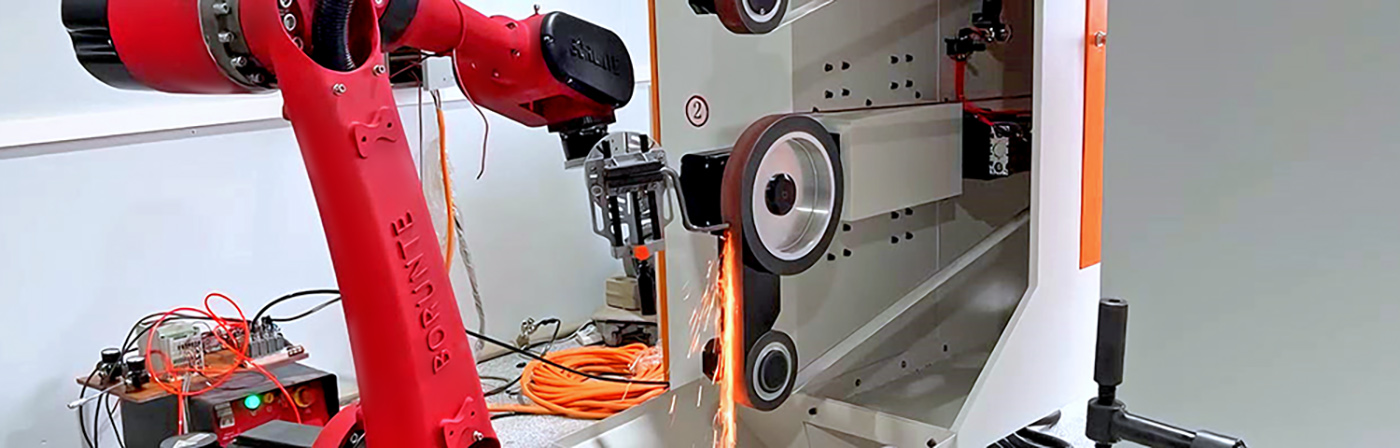

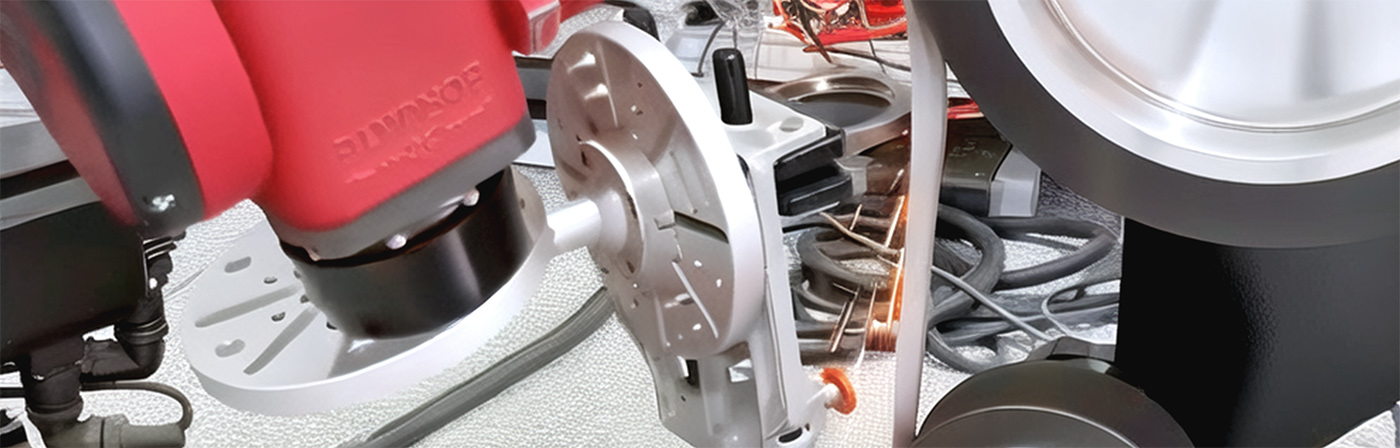

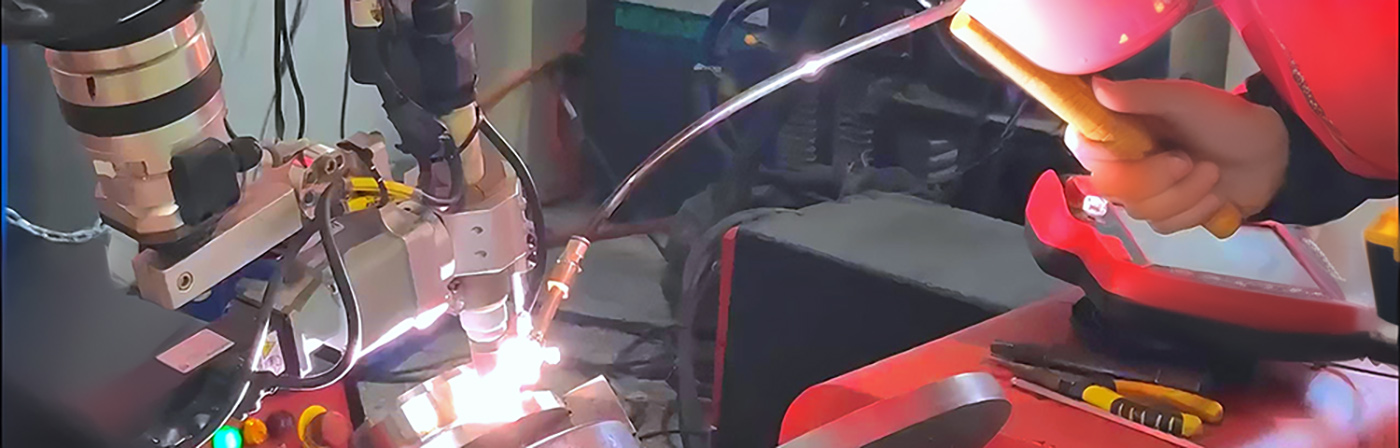

BRTIRPH1210A irobhoti nhanhatu-axis rakagadzirwa neBORUNTE kune maindasitiri ekuwelda, ekubvisa nekukuya. Yakabatana muchimiro, diki muhukuru, yakareruka muhuremu, ine mutoro mukuru we10kg uye ruoko rurefu rwe1225mm. Ruoko rwayo runotora chimiro chisina kujeka, chinoita kuti wiring ive nyore uye kufamba kuwedzere kushanduka. Yekutanga, yechipiri uye yechitatu majoini ese akashongedzerwa nepamusoro-chaizvo zvinodzikisira, uye yechina, yechishanu uye yechitanhatu majoini ese akashongedzerwa nepamusoro-chaiyo giya zvimiro. Iyo yepamusoro-yekumhanya yejoinhi kumhanya inogonesa kuchinjika kushanda. Giredhi rekudzivirira rinosvika IP54. Kudzivirira guruva uye kusapinda kwemvura. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.07mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±165° | 164°/s | |

| J2 | -95° /+70° | 149°/s | ||

| J3 | ±80° | 185°/s | ||

| Wrist | J4 | ±155° | 384°/s | |

| J5 | -130° /+120° | 396°/s | ||

| J6 | ±360° | 461°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 1225 | 10 | ±0.07 | 4.30 | 155  1. Ndeapi mabhenefiti ekutenga nyanzvi yekupolisha robhoti ruoko? BORUNTE polishing maindasitiri marobhoti anogona kuvandudza kugadzirwa kwechigadzirwa, kuvandudza mhando yechigadzirwa, kuderedza mutengo wevashandi uye njodzi yekukanganisa kwevanhu, inogona kushanda mukupisa kwakanyanya, gasi rinokuvadza uye mamwe nharaunda kuti ipe nzvimbo yakachengeteka yekushanda. 2. Ungasarudza sei kupukuta indasitiri robhoti inokodzera zvaunoda? Pakusarudza robhoti, zvinotevera zvinhu zvinofanirwa kutariswa: mutoro webasa, nzvimbo yebasa, kurongeka kwezvinodiwa, kumhanya kwekushanda, kuchengetedza zvinodiwa, hurongwa uye mashandiro ari nyore, zvinodiwa pakugadzirisa, uye zvipingamupinyi zvebhajeti. Panguva imwecheteyo, kubvunzana kunofanirwa kuitwa zvakare nevatengesi nenyanzvi kuti vawane mamwe mazano akadzama. Akakosha maficha e Professional polishing robotic ruoko: 1. Kunyatsojeka uye kudzokororwa: Basa rekupukuta rinowanzoda kufamba kwakanyatsojeka uye kushanda kwakafanana. Marobhoti eindasitiri anogona kumisa uye kudzora nemamirimita nhanho kurongeka, kuve nechokwadi chemhedzisiro mukushanda kwese. 2. Automation uye kushanda zvakanaka: Chimwe chezvinangwa zvikuru zvemarobhoti emabhizimisi ndechekuvandudza kushanda kwekugadzira. Iyo polishing maitiro anowanzo kunetsa uye anotora nguva, asi marobhoti anogona kuita mabasa nekukurumidza uye anowirirana, nekudaro achivandudza kugona kwese kwemutsetse wekugadzira.

Zvigadzirwa zvikamuBORUNTE uye BORUNTE vanobatanidzaMuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

|