BRTIRWD1606A robhoti robhoti robhoti nhanhatu-axis iro rakagadzirwa neBORUNTE yeindasitiri yekugadzira welding. Robhoti iri compact muchimiro, diki muhukuru uye chiedza muhuremu. Kuremerwa kwayo kwakanyanya 6kg uye ruoko rwayo span i1600mm. Wrist hollow chimiro, mutsara wakanyanya nyore, unochinja-chinja chiito. Yekutanga, yechipiri uye yechitatu majoini akashongedzerwa nepamusoro-chaizvo zvinodzikisira, uye yechina, yechishanu uye yechitanhatu majoini akashongedzerwa nepamusoro-chaiyo giya zvimiro, saka iyo yekumhanya-inomhanya yejoints inokwanisa kuita mabasa anochinjika. Giredhi rekudzivirira rinosvika IP54. Kudzivirira guruva uye kusapinda kwemvura. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.05mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±165° | 158°/s | |

| J2 | -95°/+70° | 143°/s | ||

| J3 | ±80° | 228°/s | ||

| Wrist | J4 | ±155° | 342°/s | |

| J5 | -130°/+120° | 300°/s | ||

| J6 | ±360° | 504°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 1600 | 6 | ±0.05 | 6.11 | 157 |

Ungasarudza sei maindasitiri welding marobhoti zvigadziriso?

1. Ziva magadzirirwo ewelding: Sarudza chaiyo yewelding process yauchange uchishandisa, yakadai seMIG, TIG, kana spot welding. Maitiro akasiyana angangoda marudzi akasiyana ezvigadziriso.

2. Nzwisisa zvirevo zvechidimbu chebasa: Ongorora zviyero, maumbirwo, uye zvinhu zvebasa rinoda kubatanidza. Iyo gadziriso inofanirwa kugara uye yakachengeteka kubata chidimbu chebasa panguva yewelding.

3. Funga nezvemhando dzejoints dzemajoini: Sarudza mhando dzemajoini (eg, butt joint, lap joint, kona yejoint) iwe unenge uri welding, sezvo izvi zvichizokanganisa dhizaini nekumisikidzwa kweiyo fixture.

4. Ongorora vhoriyamu yekugadzira: Funga nezvehuwandu hwekugadzira uye frequency iyo iyo fixture ichashandiswa. Pakugadzirwa kwepamusoro-vhoriyamu, imwe yakasimba uye yakazvimiririra inogadzirisa inogona kudikanwa.

5. Ongorora zvinodiwa zvewelding: Sarudza mwero weiyo chaiyo inodiwa kune welding purojekiti. Mamwe maapplication angangoda kushivirira kwakasimba, izvo zvinozokanganisa dhizaini nekuvaka kwechigadziriso.

General marongerwo eBRTIRWD1606A

BRTIRWD1606A inotora nhanhatu axis yakabatana robhoti chimiro, matanhatu servo motors anotyaira kutenderera kwematanho matanhatu akabatanidzwa kuburikidza nezvinoderedza uye magiya. Iine madhigirii matanhatu erusununguko, anoti kutenderera (X), ruoko rwezasi (Y), ruoko rwepamusoro (Z), kutenderera kwechanza (U), kuzungunuka kwechanza (V), uye kutenderera kwechanza (W).

BRTIRWD1606A yejoini yemuviri inogadzirwa nealuminium yakakandwa kana simbi yakakandwa, kuve nechokwadi chekusimba kwepamusoro, kumhanya, kurongeka, uye kugadzikana kwerobhoti.

-

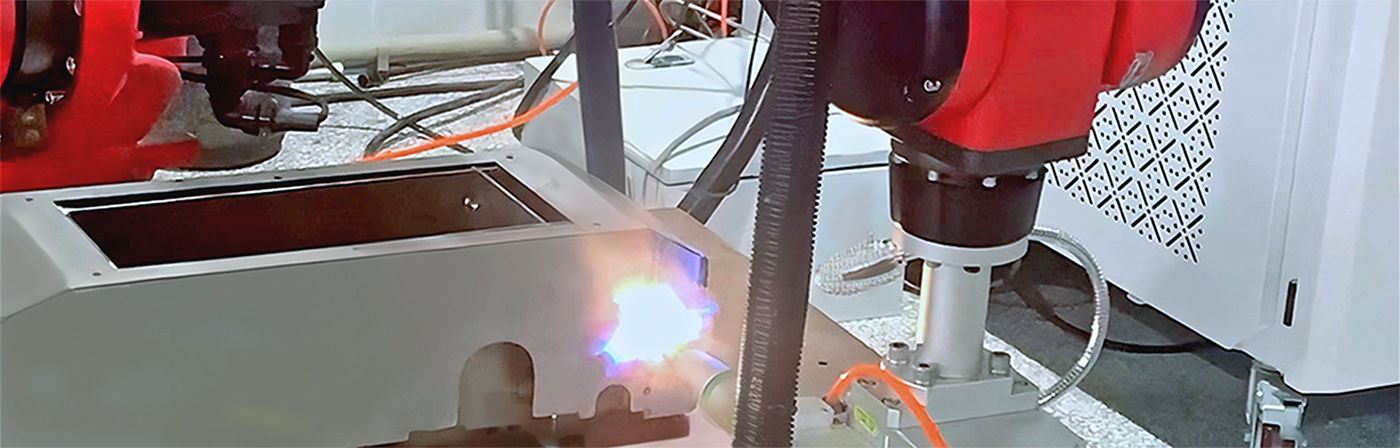

Spot welding

-

Laser welding

-

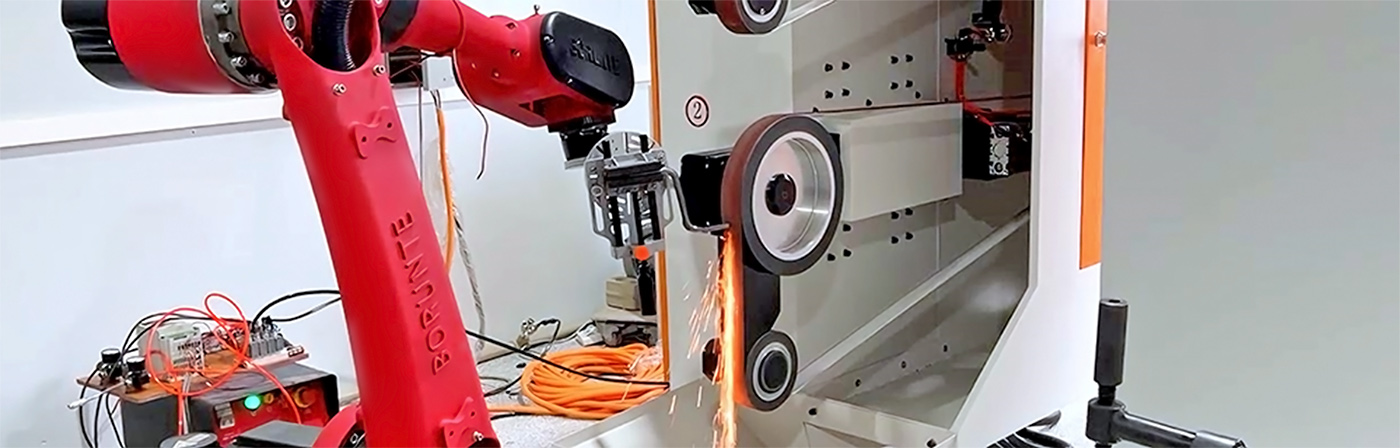

Kupukuta

-

Kucheka

Zvigadzirwa zvikamu

BORUNTE uye BORUNTE vanobatanidza

MuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

-

-

-

Top