BRTIRWD2206A robhoti robhoti robhoti nhanhatu-axis rakagadzirwa neBORUNTE yeindastiri yekugadzira welding. Robhoti iri compact muchimiro, diki muhukuru uye chiedza muhuremu. Kuremerwa kwayo kukuru i6kg uye kureba kwayo kwemaoko i2200mm. Wrist hollow chimiro, mutsara wakanyanya nyore, chiitiko chinoshanduka. Giredhi rekudzivirira rinosvika IP54 paruoko uye IP40 pamuviri. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.08mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±155° | 106°/s | |

| J2 | -130°/+68° | 135°/s | ||

| J3 | -75°/+110° | 128°/s | ||

| Wrist | J4 | ±153° | 168°/s | |

| J5 | -130°/+120° | 324°/s | ||

| J6 | ±360° | 504°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 2200 | 6 | ±0.08 | 5.38 | 237 |

Kureba kweruoko kunopesvedzera sei kushandiswa kwewelding?

1.Reach uye Workspace: Ruoko rwakareba runobvumira robot kuti iwane nzvimbo yakakura yekushanda, ichiita kuti isvike kure kana nzvimbo dzakaoma welding pasina kudiwa nguva nenguva. Izvi zvinowedzera kushanda zvakanaka uye zvinoderedza kudiwa kwekupindira kwevanhu.

2.Flexibility: Kureba kweruoko kunopa kushanduka kukuru, zvichiita kuti robhoti iite uye weld yakatenderedza zvipingamupinyi kana munzvimbo dzakasimba, zvichiita kuti ive yakakodzera kune welding yakaoma uye isina kuumbwa zvidimbu zvebasa.

3.Makuru Mashandiro ezvimedu: Maoko marefu akakodzera zviri nani kusungirira zvidimbu zvakakura zvebasa sezvo zvichigona kuvhara nzvimbo yakawanda pasina kudzorerazve. Izvi zvinobatsira mumaindasitiri umo mahombe ezvimiro zvemukati anoda kusungirirwa.

4.Joint Accessibility: Mune mamwe mawelding applications, pane chaiwo makona kana majoini anogona kuve akaoma kuwana neapfupi-ruoko robhoti. Ruoko rurefu runogona kusvika nekupinza majoini aya akaoma-kusvika nyore nyore.

5.Kugadzikana: Maoko akareba dzimwe nguva anogona kunge ari kunyanya kuzununguka uye kukanganisa, kunyanya kana uchibata nemari inorema kana kuita welding-speed. Kuve nechokwadi chekuomarara kwakaringana uye kurongeka kunove kwakakosha kuchengetedza welding mhando.

6.Welding Speed: Kune mamwe maitirwo emagetsi, robhoti yakareba-ruoko inogona kunge iine mitsara yakakwirira yepamusoro nekuda kwenzvimbo yayo yekushanda yakakura, inogona kuwedzera kubereka kuburikidza nekuderedza welding cycle times.

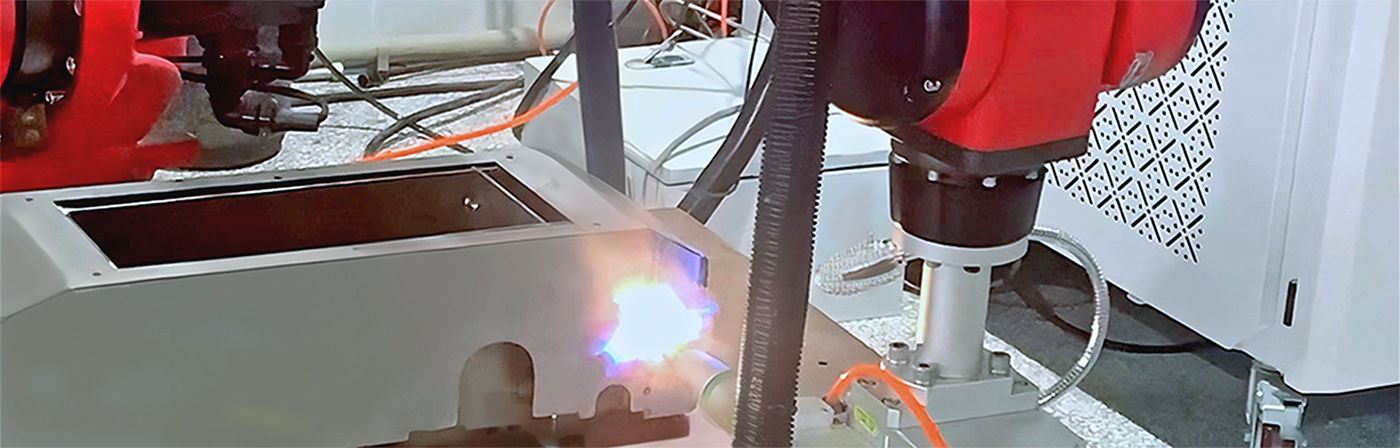

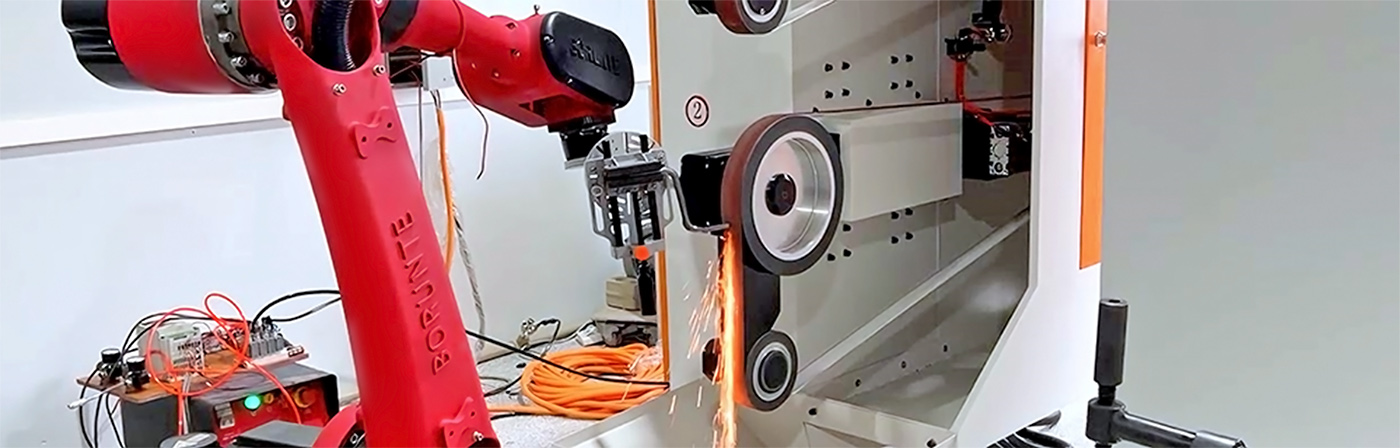

Nheyo yekushanda yewelding marobhoti:

Welding marobhoti anotungamirwa nevashandisi uye anoshanda nhanho nhanho zvinoenderana nemabasa chaiwo. Munguva yekutungamira maitiro, robhoti rinongoyeuka chinzvimbo, chimiro, mafambiro ekufamba, welding paramita, nezvimwe zvechiito chega chega chinodzidziswa, uye chinogadzira chirongwa chinoramba chichiita mabasa ese. Mushure mekupedza dzidziso, ingopa iro robhoti kuraira kwekutanga, uye robhoti ichanyatso kutevedzera chiito chekudzidzisa, nhanho nhanho, kupedzisa mabasa ese, kudzidzisa chaiko uye kubereka.

-

Spot welding

-

Laser welding

-

Kupukuta

-

Kucheka

Zvigadzirwa zvikamu

BORUNTE uye BORUNTE vanobatanidza

MuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

-

-

-

Top