BRTIRUS2520B mhando robhoti irobhoti nhanhatu-axis iro rakagadzirwa neBORUNTE kune mamwe anotutumadza, anogaro dzokorora uye anodzokororwa kwenguva refu maoparesheni kana mashandiro munzvimbo dzine njodzi uye dzakakasharara. Hurefu hwemaoko hunosvika 2570mm. Mutoro mukuru ndeye 200kg. Inochinjika ine madhigirii akawanda erusununguko. Inokodzera kurodha uye kuburitsa, kubata, stacking etc. Giredhi rekudzivirira rinosvika IP40. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.2mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±160° | 63°/s | |

| J2 | -85°/+35° | 52°/s | ||

| J3 | -80°/+105° | 52°/s | ||

| Wrist | J4 | ±180° | 94°/s | |

| J5 | ±95° | 101°/s | ||

| J6 | ±360° | 133°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 2570 | 200 | ±0.2 | 9.58 | 1106 |

Zvinhu zvina zvakakosha zveBTIRUS2520B

1. Iyo BRTIRUS2520B i-6-axis industrial robot ine yepamusoro-performance motion control platform iyo inopa kushanda kukuru, kukurumidza kugadzirisa kukurumidza, uye kuvimbika kwemabhizimisi.

2. Robhoti iyi inokodzera zvikamu zvakasiyana-siyana, zvinosanganisira mota, zvemagetsi, zvigadzirwa zvevatengi, uye michina, uye kugona kwayo kwakanakisa kwekugadzirisa kunosangana nezvinodiwa zveakawanda otomatiki ekugadzira mabasa. Yakavakwa kuti imirisane neyakaomarara maindasitiri nharaunda, ichiendesa inogara uye inovimbika kuita maererano nekumhanya uye nekurongeka.

3. Iri robhoti reindasitiri rine mutoro wepamusoro unosvika 200kg uye yakanakira zvakasiyana-siyana zvinoda automated operations.

4. Kupfupisa, iyo BRTIRUS2520B yakanyatsoshongedzerwa kukwenenzvera magadzirirwo ekugadzira uye isarudzo yakanakisa kune rinorema-basa reindasitiri robhoti application. Inogona kushandiswa muzvikamu zvakaita se otomatiki, musangano, welding, uye kubata zvinhu nekuti kune yayo yakasimba inofamba inodzora chikuva, kusimba kwakavimbika, uye indasitiri inotungamira agility.

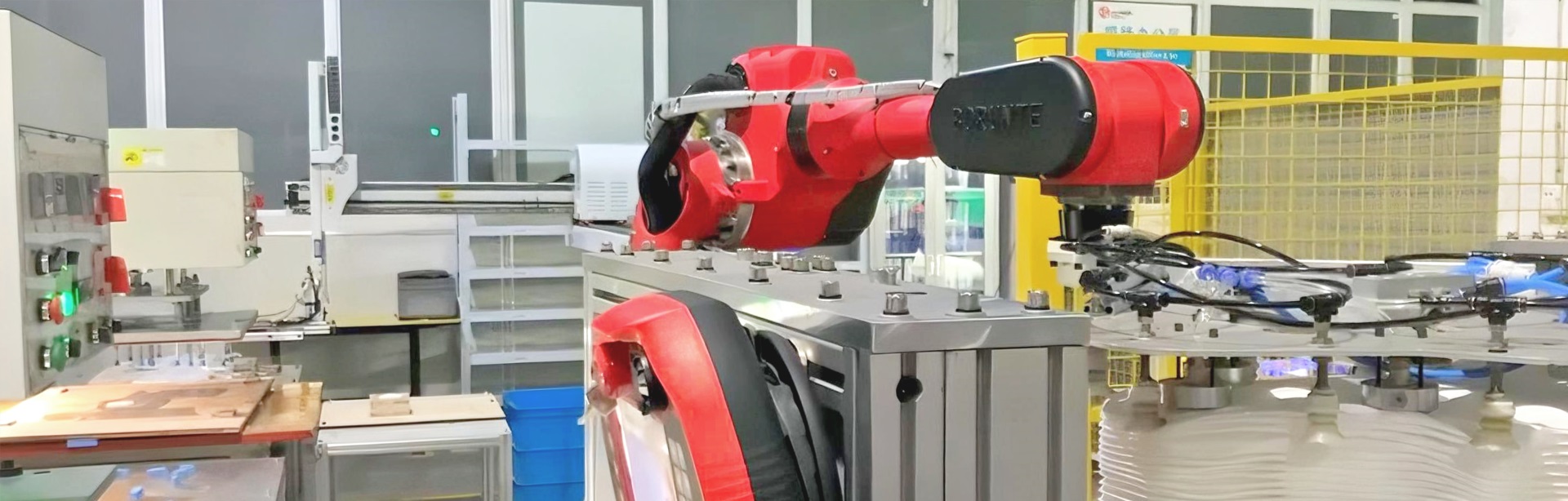

1. Assembly Line Optimization: Iri robhoti yeindasitiri inokunda mumitsetse yezviitwa, inobata zvinhu zvakapfava nemazvo uye kuderedza kukanganisa kwevanhu. Iyo inowedzera zvakanyanya kumhanya kwekugadzira uye inovimbisa yemhando yepamusoro nekuita otomatiki kudzokorora zviitiko, zvichikonzera kuchengetwa kwemutengo uye kuwedzera kugutsikana kwevatengi.

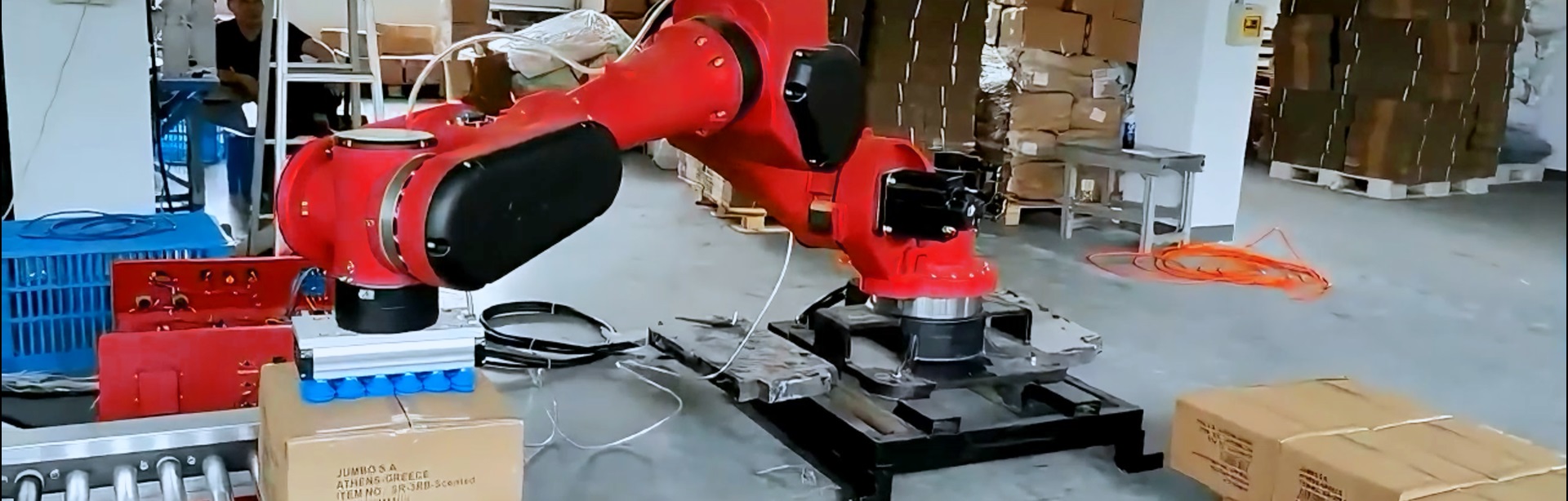

2. Material Kubata uye Packaging: Robhoti inogadzirisa zvinhu zvekubata uye kurongedza maitiro nekuvakwa kwayo kwakasimba uye inodzoreredza grippers. Inogona kurongedza zvinhu nenzira inobudirira, kuisa zvigadzirwa nenzira yakarongeka, uye kutakura mitoro mikuru zviri nyore, kurerutsa zvinhu uye kuderedza kudiwa kwebasa remaoko.

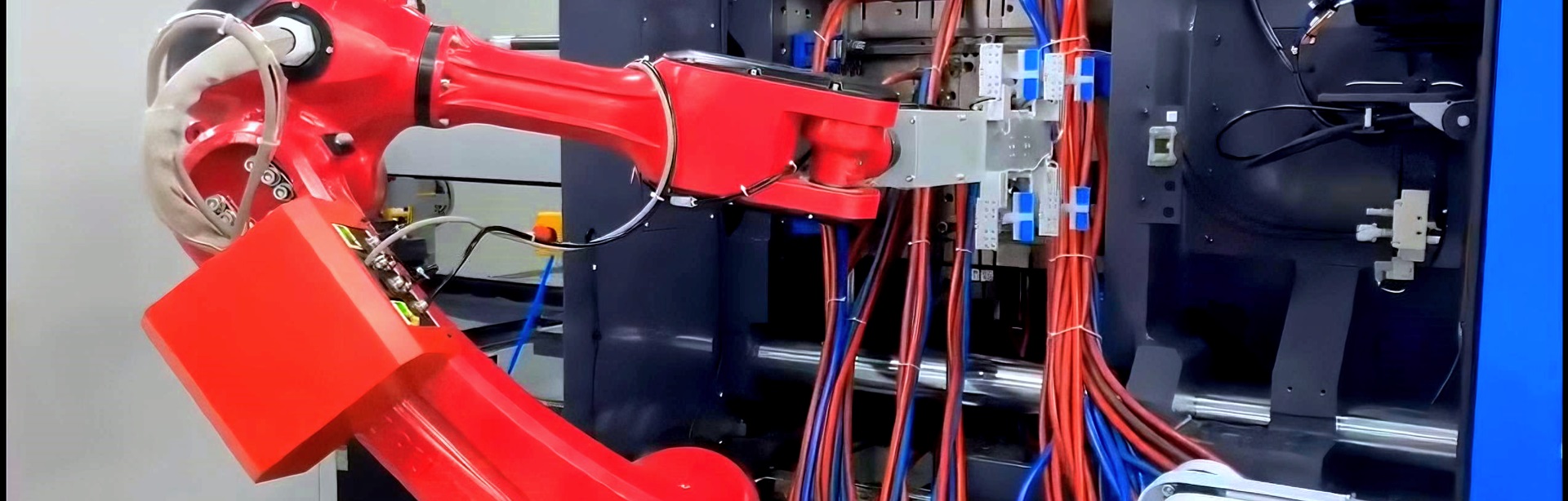

3. Welding uye Fabrication: The autonomous general chinangwa robhoti robhoti yakanakira welding uye machira mabasa nokuti inobudisa zvakarurama uye anowirirana welds. Nekuda kwesimba rayo rekuona masisitimu uye kutonga kwekufamba, inogona kutaurirana zvimiro zvakaoma, ichipa yakagadziridzwa welding mhando uye kuchengetedza marara.

-

transport

-

stamping

-

Jekiseni kuumba

-

ChiPolish

Zvigadzirwa zvikamu

BORUNTE uye BORUNTE vanobatanidza

MuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

-

-

-

Top