BRTIRUS1510A irobhoti-axis matanhatu rakagadzirwa neBORUNTE kune yakaoma maapplication ane akawanda madhigirii erusununguko. Mutoro mukuru ndeye 10kg, kureba kweruoko i1500mm. Kureruka kurema ruoko dhizaini, compact uye yakapusa mechanicha chimiro, mumamiriro ekumhanya kwazvo kufamba, inogona kuitwa munzvimbo diki yebasa inochinjika basa, inosangana nezvinodiwa zvekuchinjika kugadzirwa. Iine madhigirii matanhatu ekuchinja. Inokodzera kupenda, welding, injection molding, stamping, forging, handling, loading, assembling, etc. Inotora HC control system, inokodzera jekiseni molding machine range kubva ku200T-600T. Giredhi rekudzivirira rinosvika IP54. Kudzivirira guruva uye kusapinda kwemvura. Iyo yekudzokorora yekumisikidza kurongeka ndeye ± 0.05mm.

Accurate Positioning

Fast

Hupenyu Hurefu Hwebasa

Low Kutadza Mwero

Deredza Basa

Telecommunication

| Item | Range | Max speed | ||

| Arm | J1 | ±165° | 190°/s | |

| J2 | -95°/+70° | 173°/s | ||

| J3 | -85°/+75° | 223°/s | ||

| Wrist | J4 | ±180° | 250°/s | |

| J5 | ±115° | 270°/s | ||

| J6 | ±360° | 336°/s | ||

|

| ||||

| Kureba kweruoko (mm) | Kutakura Kugona (kg) | Kudzokororwa Kwenzvimbo Yechokwadi (mm) | Kunobva Simba (kVA) | Huremu (kg) |

| 1500 | 10 | ±0.05 | 5.06 | 150 |

Kushandiswa kweBRTIRUS1510A

1. Kubata 2. Kudhinda 3. Jekiseni molding 4. Kukuya 5. Kucheka 6. Deburring7. Gluing 8. Stacking 9. Kupfapfaidza, nezvimwewo.

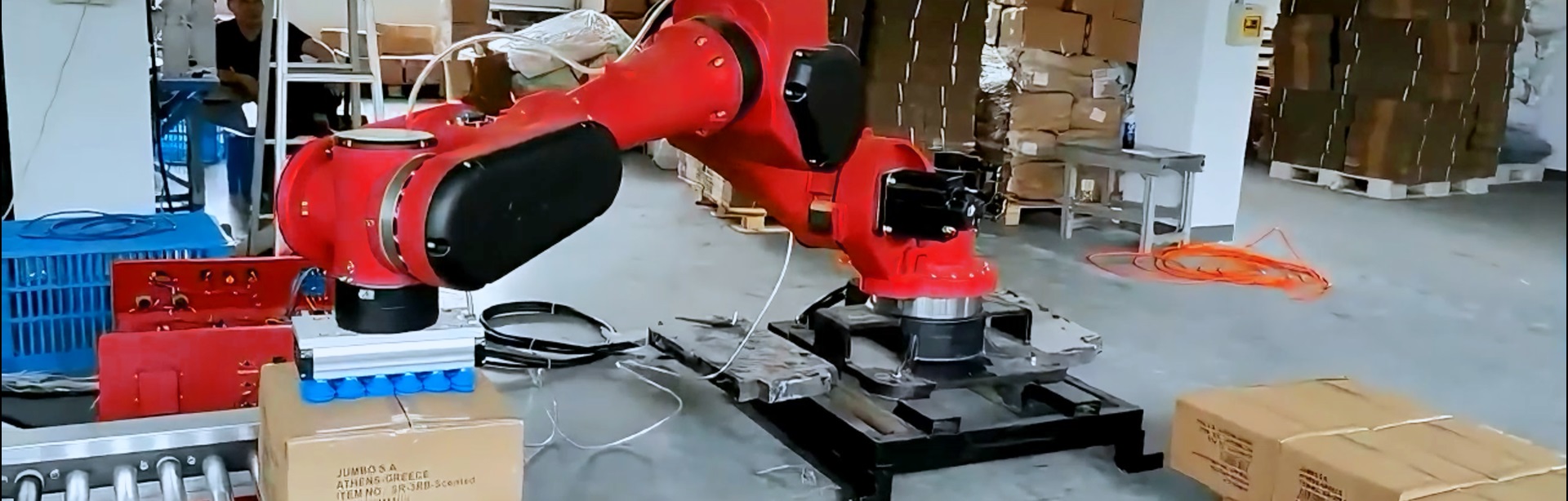

1.Material Handling: Marobhoti anoshandiswa kubata uye kutakura zvinhu zvinorema mumafekitori uye matura. Vanogona kusimudza, kurongedza, uye kufambisa zvinhu nenzira kwayo, kuwedzera kushanda uye kuderedza njodzi yekukuvara kwebasa.

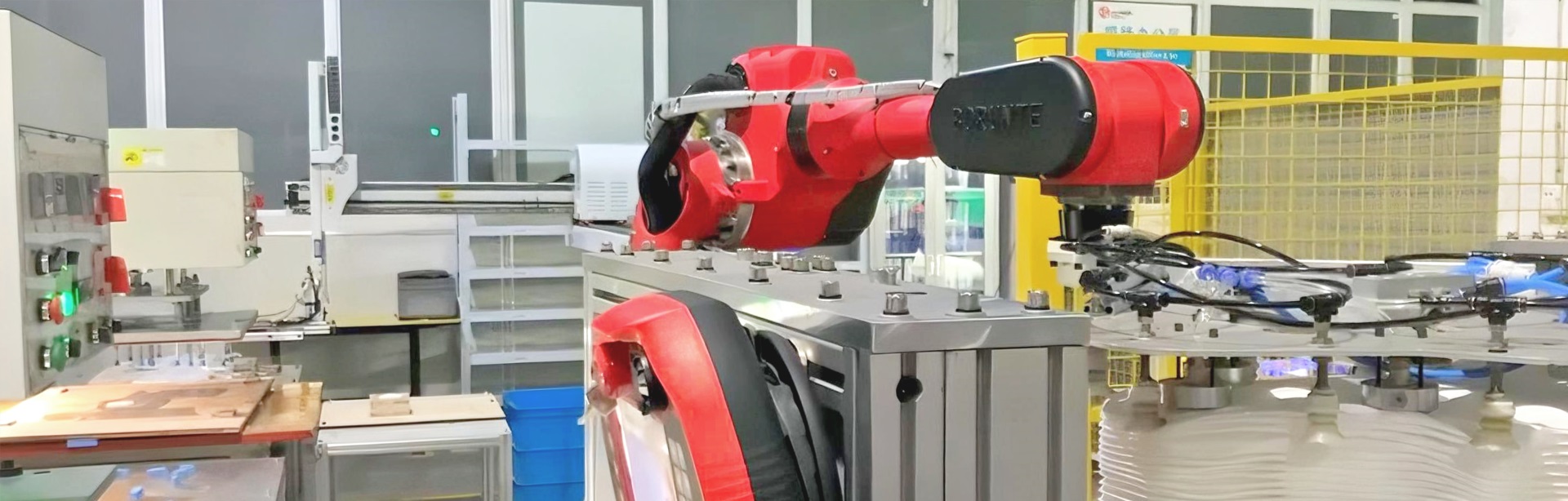

2.Welding: Nekukwirira kwayo kwakakwirira uye kushanduka, robot yakanyatsokodzera kushandiswa kwekugadzirisa, kupa welds inowirirana uye yakavimbika.

3.Kupfapfaidza: Marobhoti eindasitiri anoshandiswa kupenda nzvimbo dzakakura mumaindasitiri akadai semotokari, aerospace, uye zvinhu zvevatengi. Kudzora kwavo chaiko kunovimbisa yunifomu uye yemhando yepamusoro kupera.

4.Inspection: Irobhoti yepamusoro yekuona maitiro ekubatanidza inoita kuti iite kuongorora kwehutano, kuve nechokwadi kuti zvigadzirwa zvinosangana nepamusoro-soro.

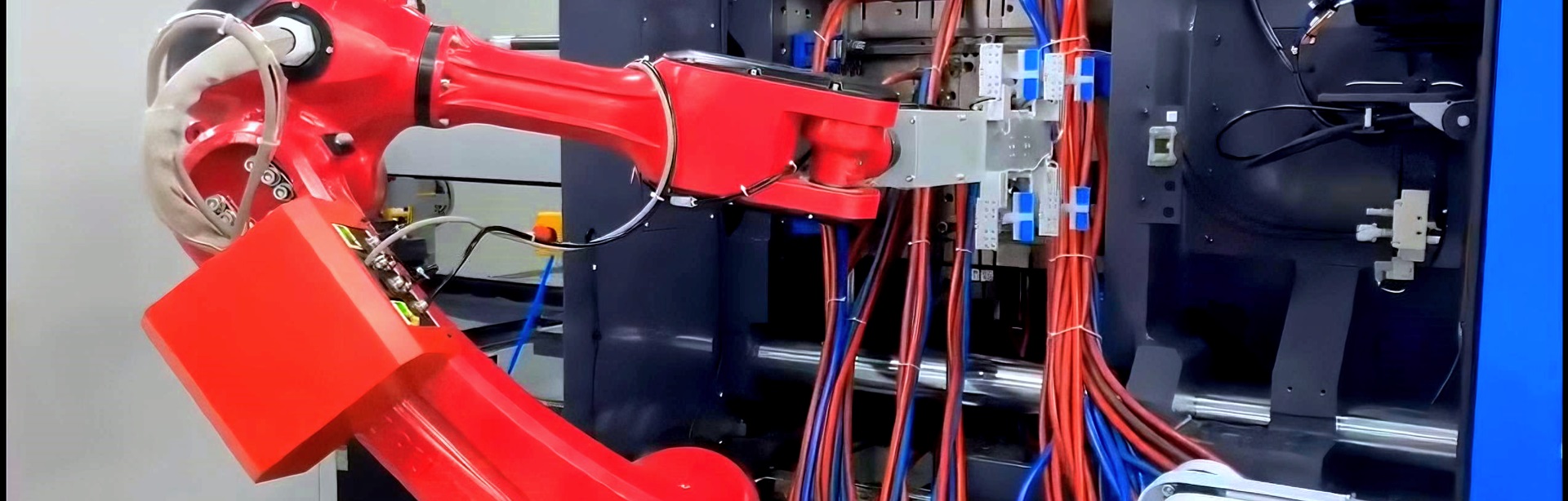

5.CNC Machining: BRTIRUS1510A inogona kubatanidzwa muComputer Numerical Control (CNC) michina kuti iite yakaoma milling, kucheka, uye kuchera maitiro nepamusoro-soro uye kudzokorora.

Robhoti yekuongorora bvunzo usati wasiya fekitori yeBORUNTE:

1.Robot ndeyepamusoro-chaiyo yekuisa michina, uye hazvidzivisiki kuti zvikanganiso zvichaitika panguva yekuiswa.

2.Robhoti imwe neimwe inofanira kuiswa pasi pekunyatsoona kushandiswa kwekugadzirisa kushandiswa uye kugadziriswa kwemubhadharo usati wabuda mufekitari.

3.Muchikamu chinonzwisisika chekuenzanisa, kureba kweshaft, iyo inoderedza kukurumidza, eccentricity uye mamwe maparameter anobhadharwa kuti ave nechokwadi chekufamba kwemidziyo uye kunyatsoita track.

4.After calibration compensation iri mukati mehutano hwakakodzera (ona tafura yekuenzanisa kuti uwane mamwe mashoko), kana kubhadhara kutumirwa kusiri mukati mehutano hwakakodzera, ichadzoserwa kumutsara wekugadzira kuti uongorore zvakare, kugadzirisa uye kuungana, uye ipapo. calibrated kusvika wakwanisa.

-

transport

-

stamping

-

Jekiseni kuumba

-

ChiPolish

Zvigadzirwa zvikamu

BORUNTE uye BORUNTE vanobatanidza

MuBORUNTE ecosystem, BORUNTE ine basa reR&D, kugadzira, uye kutengesa marobhoti uye manipulators. BORUNTE vanobatanidza vanoshandisa indasitiri yavo kana mabhenefiti emumunda kupa terminal application dhizaini, kusanganisa, uye mushure mekutengesa sevhisi yeBORUNTE zvigadzirwa zvavanotengesa. BORUNTE uye BORUNTE vanobatanidza vanozadzisa mabasa avo uye vakazvimiririra kune mumwe nemumwe, vachishanda pamwe chete kukurudzira ramangwana rakajeka reBORUNTE.

-

-

-

Top