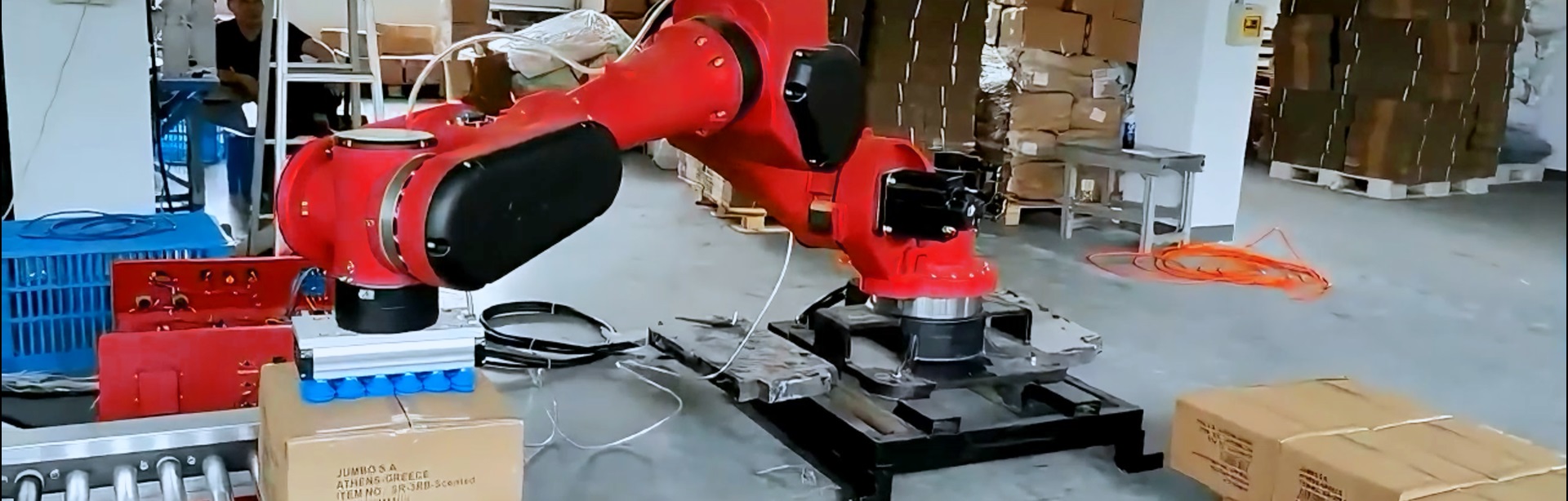

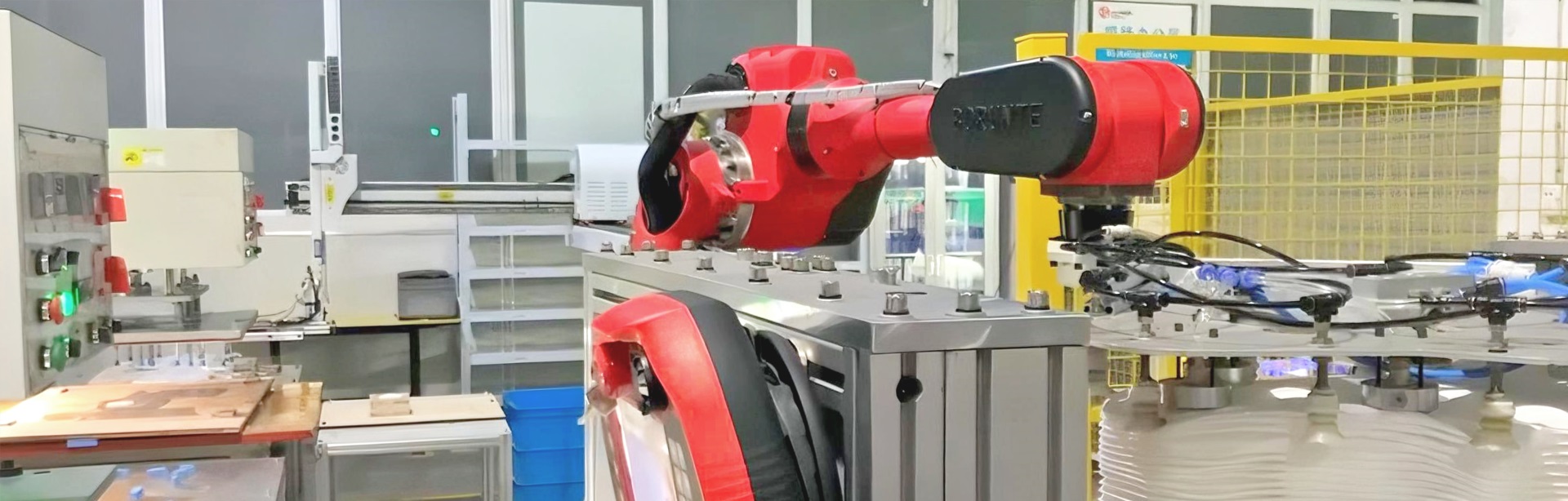

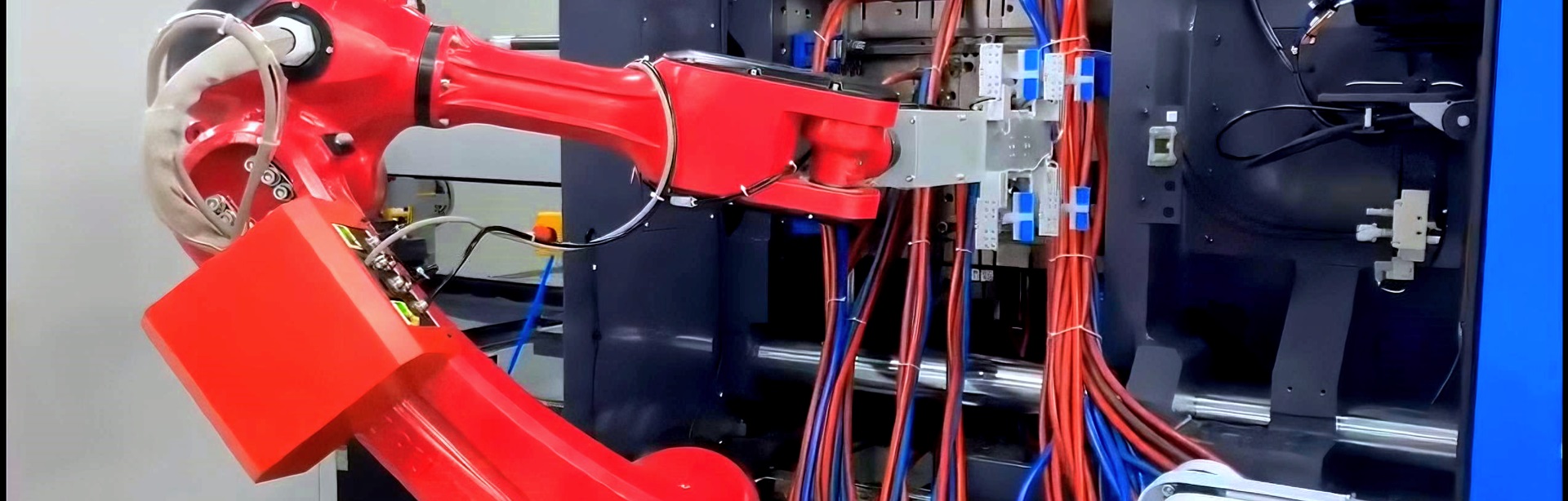

BRTIRUS2110A is a six-axis robot developed by BORUNTE for complex applications with multiple degrees of freedom. The maximum arm length is 2100mm. The maximum load is 10kg. It has six degrees of flexibility. Suitable for welding, loading and unloading, assembling etc. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±155° |

110°/s |

|

|

J2 |

-90 ° (-140 °, adjustable downward probe) /+65 ° |

146°/s |

||

|

J3 |

-75°/+110° |

134°/s |

||

|

Wrist |

J4 |

±180° |

273°/s |

|

|

J5 |

±115° |

300°/s |

||

|

J6 |

±360° |

336°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2100 |

10 |

±0.05 |

6.48 |

230

The mechanical structures of industrial robots can vary depending on their type and purpose, but the fundamental components typically include: 2. Joints : Industrial robots have multiple joints that enable them to move and articulate like a human arm. 3. Sensors: Industrial robots often have various sensors integrated into their mechanical structure. These sensors provide feedback to the robot's control system, allowing it to monitor its position, orientation, and interaction with the environment. Common sensors include encoders, force/torque sensors, and vision systems.

1. What is an industrial robot arm? 2.What are the advantages of using industrial robot arms?

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|