BRTIRWD1506A type robot is a six-axis robot developed by BORUNTE for the development of the welding application industry. The robot has compact structure, small volume and light weight. The maximum load is 6kg, the maximum arm length is 1600mm. The wrist applies hollow structure with more convenient trace and flexible action. The protection grade reaches IP54 . Dust-proof and water-proof. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±165° |

163°/s |

|

|

J2 |

-100°/+70° |

149°/s |

||

|

J3 |

±80° |

223°/s |

||

|

Wrist |

J4 |

±150° |

169°/s |

|

|

J5 |

±110° |

270°/s |

||

|

J6 |

±360° |

398°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1600 |

6 |

±0.05 |

4.64 |

166 |

Significant features of using the welding robot:

1. Stabilize and improve welding quality to ensure its uniformity.

Using Robot welding, the welding parameters for each weld are constant, and the weld quality is less affected by human factors, reduces the requirements for workers' operating skills, so the welding quality is stable.

2. Improve productivity.

The robot can be continuously produced 24 hours a day. In addition, with the application of high-speed and efficient welding technology, the efficiency of Robot welding welding is improved more significantly.

3. Clear product cycle, easy to control product output.

The production rhythm of robots is fixed, so the production plan is very clear.

4.Shorten the cycle of product transformation

Can achieve welding automation for small batch products. The biggest difference between a robot and a specialized machine is that it can adapt to the production of different workpieces by modifying the program.

-

Spot welding

-

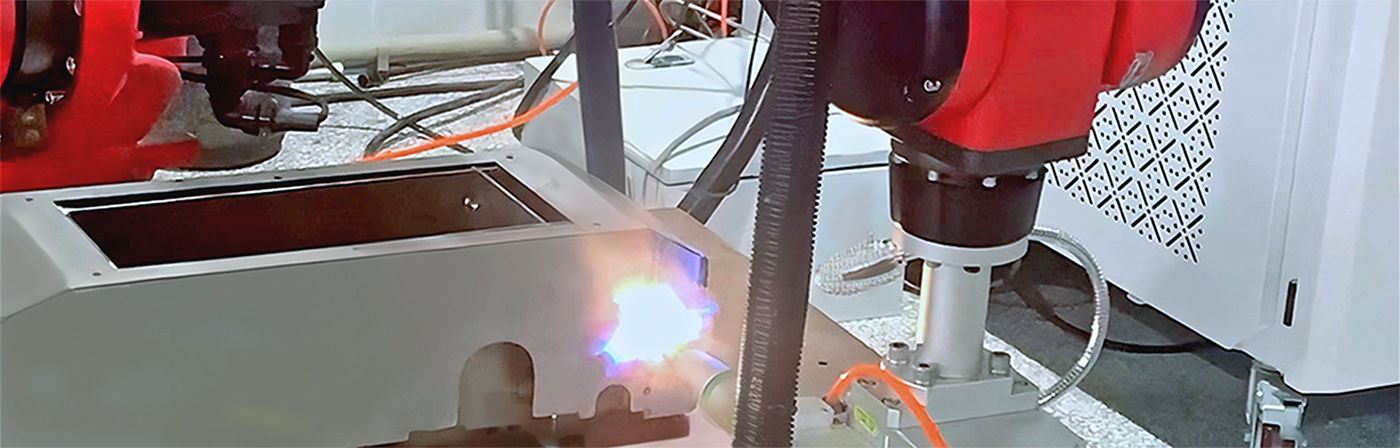

Laser welding

-

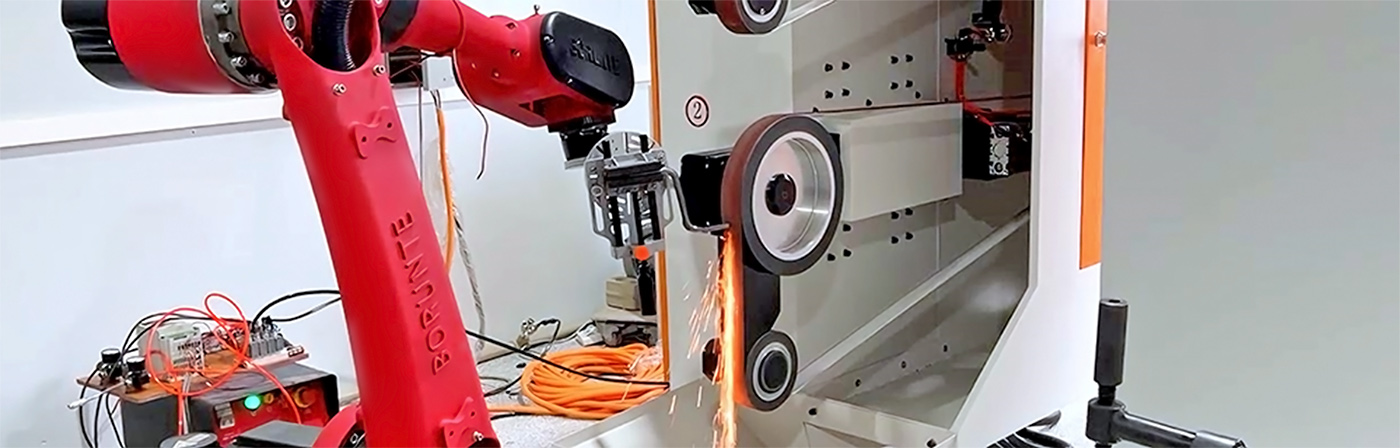

Polishing

-

Cutting

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top