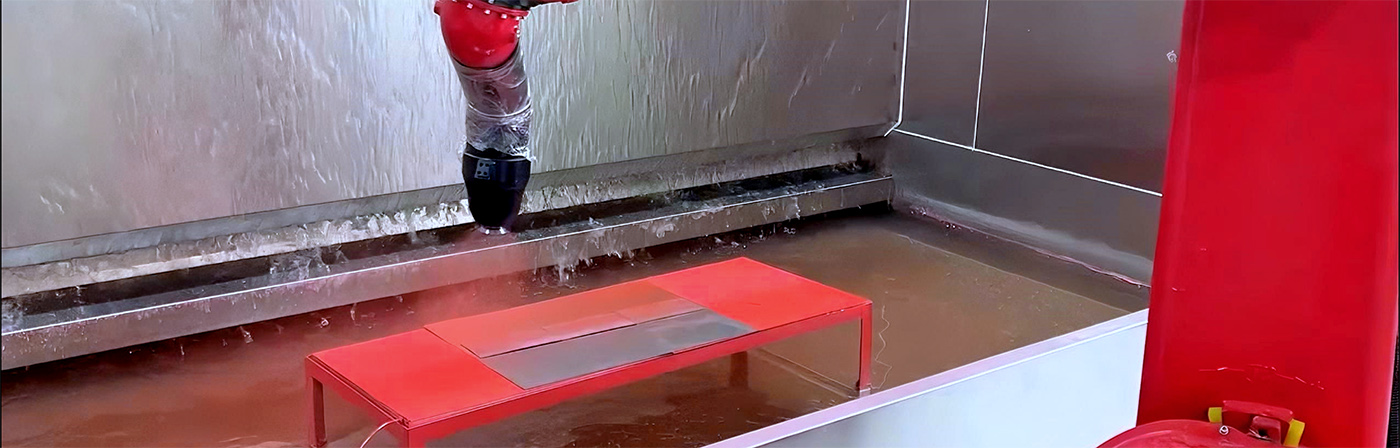

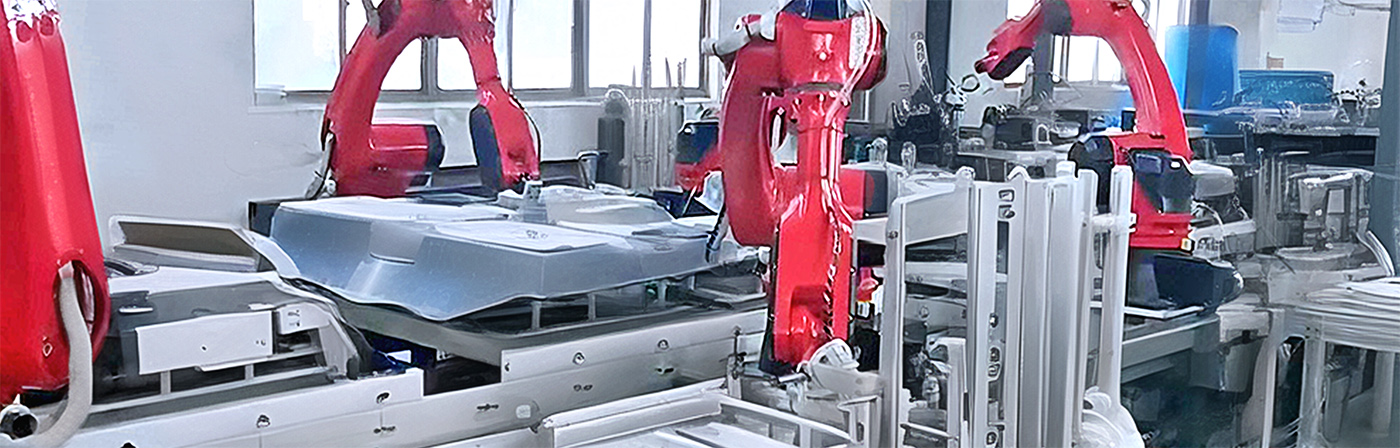

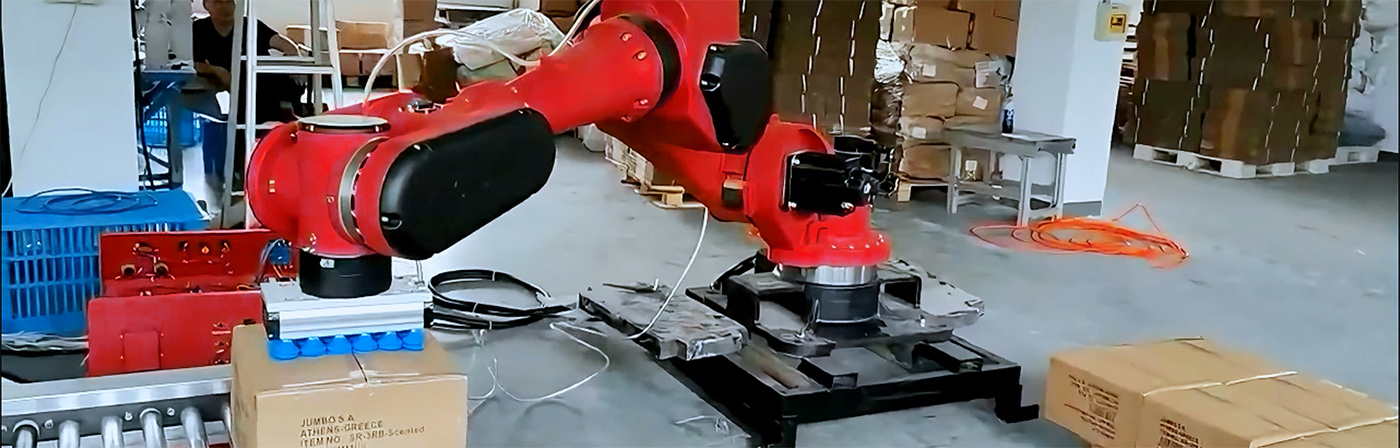

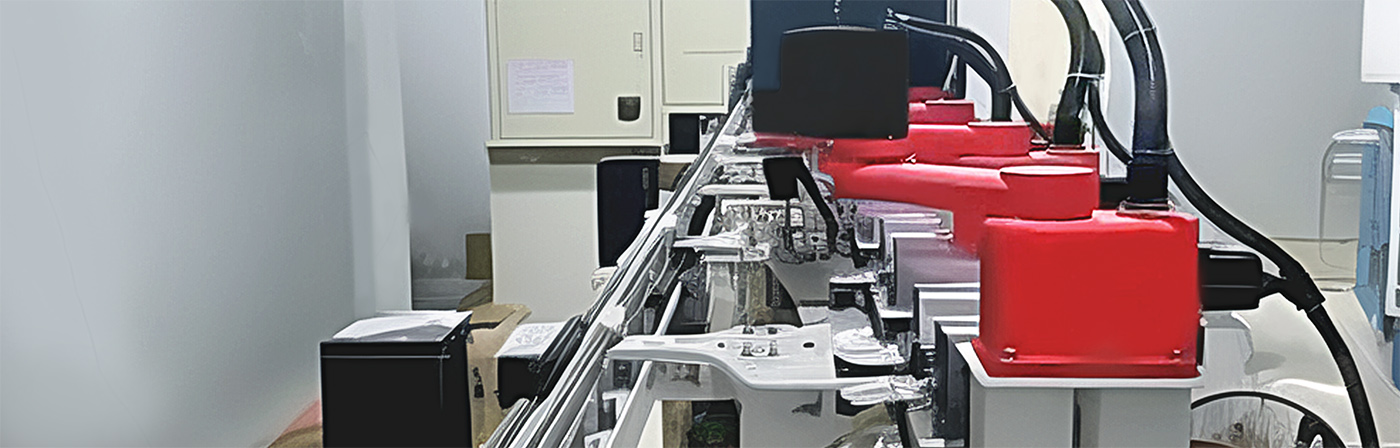

BRTIRSE2013A is a six-axis robot developed by BORUNTE for the spraying application industry. It has an ultra-long arm span of 2000mm and a maximum load of 13kg. It has a compact structure, is highly flexible and technologically advanced, it can be applied to a wide range of spraying industry and accessories handling field. The protection grade reaches IP65 . Dust-proof, water-proof. The repeat positioning accuracy is ±0.5mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±162.5° |

101.4°/s |

|

|

J2 |

±124° |

105.6°/s |

||

|

J3 |

-57°/+237° |

130.49°/s |

||

|

Wrist |

J4 |

±180° |

368.4°/s |

|

|

J5 |

±180° |

415.38°/s |

||

|

J6 |

±360° |

545.45°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2000 |

13 |

±0.5 |

6.38 |

385

Multi usage programmable industrial robot used in spraying industrial:

What types of paintings can industrial spraying robots apply? 2.Furniture Finishes: Robots can apply paints, stains, lacquers, and other finishes to furniture pieces, achieving consistent and smooth results. 3.Electronics Coatings: Industrial spraying robots are used to apply protective coatings to electronic devices and components, offering protection against moisture, chemicals, and environmental factors. 4.Appliance Coatings: In appliance manufacturing, these robots can apply coatings to refrigerators, ovens, washing machines, and other household appliances. 5.Architectural Coatings: Industrial spraying robots can be employed in architectural applications to coat building materials, such as metal panels, cladding, and pre-fabricated elements. 6.Marine Coatings: In the marine industry, robots can apply specialized coatings to ships and boats for protection against water and corrosion.

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|