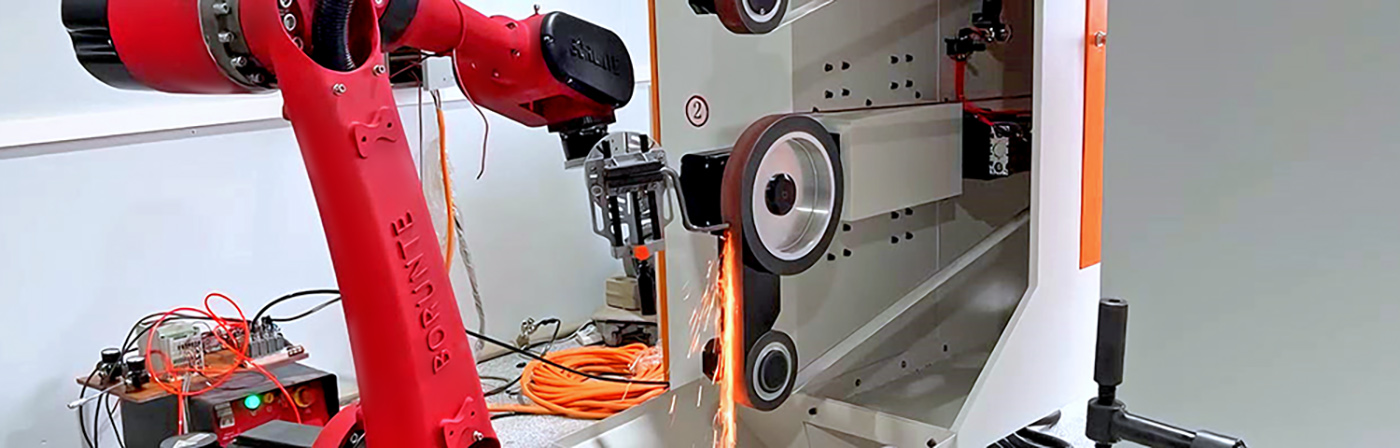

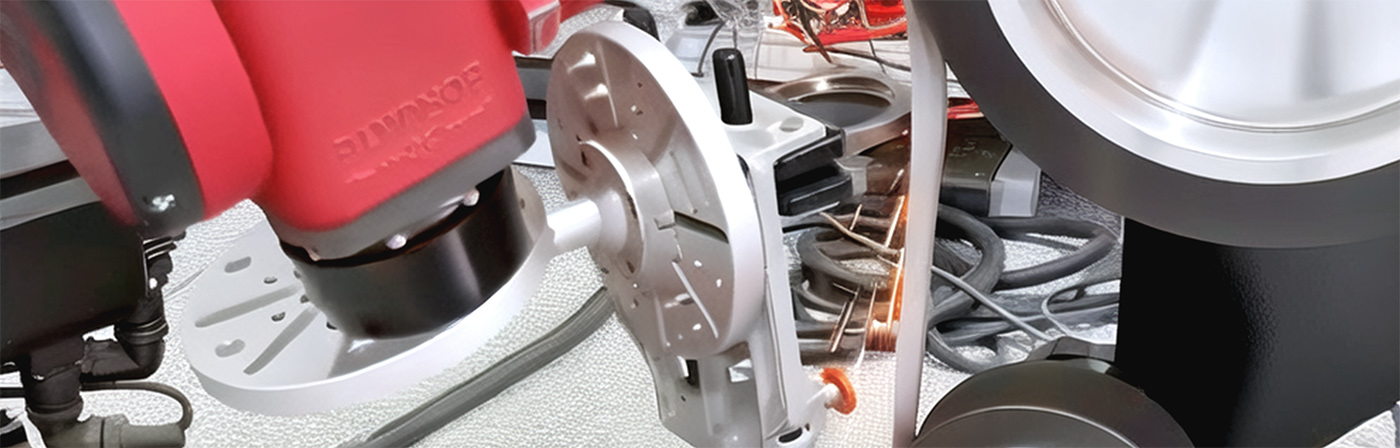

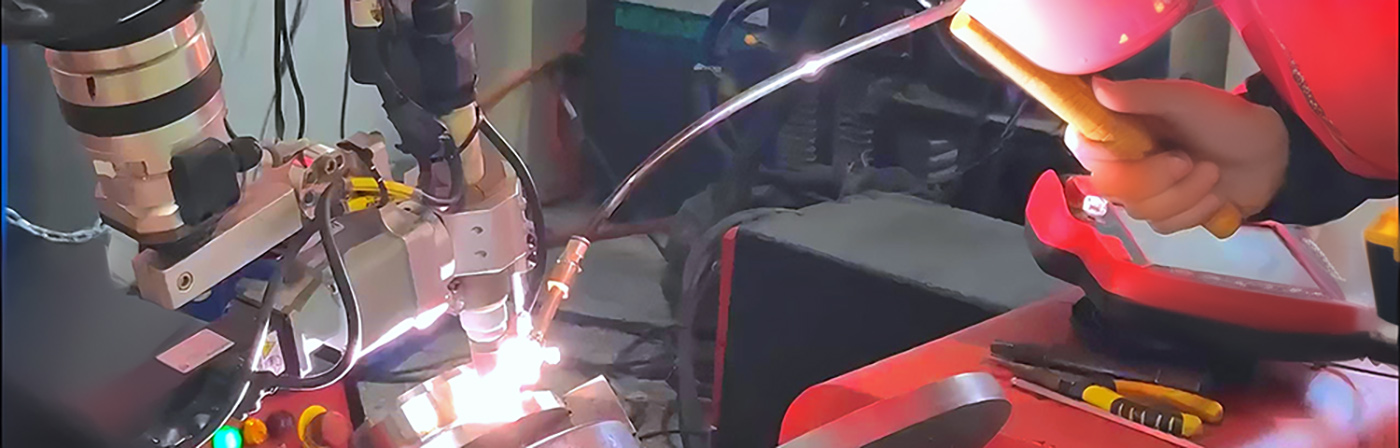

BRTIRPH1210A is a six-axis robot developed by BORUNTE for the welding, deburring and grinding application industries. It is compact in shape, small in size, light in weight, with a maximum load of 10kg and an arm span of 1225mm. Its wrist adopts a hollow structure, which makes the wiring more convenient and the movement more flexible. The first, second and third joints are all equipped with high-precision reducers, and the fourth, fifth and sixth joints are all equipped with high-precision gear structures. The high-speed joint speed enables flexible operation. The protection grade reaches IP54. Dust-proof and water-proof. The repeat positioning accuracy is ±0.07mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±165° |

164°/s |

|

|

J2 |

-95° /+70° |

149°/s |

||

|

J3 |

±80° |

185°/s |

||

|

Wrist |

J4 |

±155° |

384°/s |

|

|

J5 |

-130° /+120° |

396°/s |

||

|

J6 |

±360° |

461°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1225 |

10 |

±0.07 |

4.30 |

155

1. What are the benefits of purchasing professional polishing robotic arm? BORUNTE polishing industrial robots can improve production efficiency, improve product quality, reduce labor costs and human error risks, it can work in high temperature, harmful gas and other environments to provide a safer working environment. 2. How to choose a polishing industrial robot that suits your needs? When choosing a robot, the following factors should be considered: workload, workspace, accuracy requirements, working speed, safety requirements, programming and operational simplicity, maintenance requirements, and budget constraints. At the same time, consultations should also be conducted with suppliers and professionals to obtain more detailed suggestions. Significant features of Professional polishing robotic arm: 1. Precision and repeatability: Polishing work typically requires highly precise movement and consistent operation. Industrial robots can position and control with millimeter level accuracy, ensuring consistent results in every operation. 2. Automation and efficiency: One of the main purposes of industrial robots is to improve production efficiency. The polishing process is usually cumbersome and time-consuming, but robots can perform tasks in a fast and consistent manner, thereby improving the overall efficiency of the production line.

Products categoriesBORUNTE and BORUNTE integratorsIn the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

|