Industry News

-

What is robot protective clothing and what are the functions of robot protective clothing?

Robot protective clothing is mainly used as a protective device to protect various industrial robots, mainly applied to automation equipment in industries such as automobile manufacturing, metal products, and chemical plants. What are the scope of use for robot protecti...Read more -

How to choose robot protective clothing? How to make robot protective clothing?

1. Robot protective clothing performance: There are many types of robot protective clothing performance, and the protective performance varies depending on the material selection. So when choosing protective clothing, it is important to pay attention to the actual workin...Read more -

How does a robot palletizer work?

Robot stacking is a high-performance automated equipment used to automatically grab, transport, and stack various packaged materials (such as boxes, bags, pallets, etc.) on the production line, and neatly stack them on pallets according to specific stacking modes. The wo...Read more -

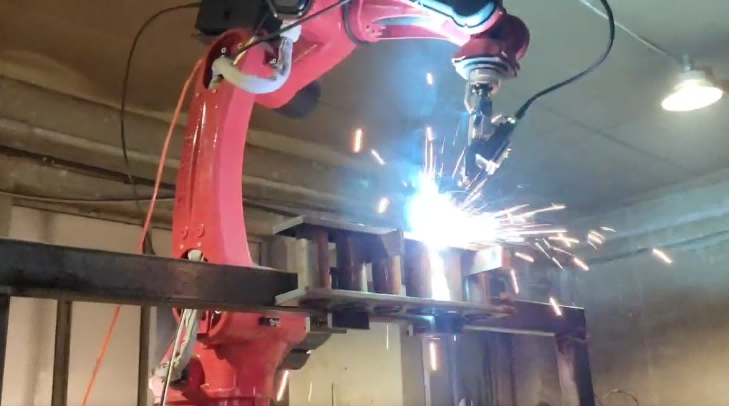

Weld seam tracking technology, the “golden eye” of industrial robots!

The industrial robot market is rapidly emerging like mushrooms after rain and is becoming a new engine for global manufacturing. Behind the global sweep of intelligent manufacturing, machine vision technology, known as the "eye-catching" role of industrial robots, plays ...Read more -

What is the difference between laser welding machines and traditional welding methods?

Laser welding machines and traditional welding methods are currently two commonly used different welding processes. Laser welding machines use laser beams to weld workpieces, while traditional welding methods rely on arc, gas welding, or friction to achieve welding. Ther...Read more -

Summary of practical operation and application skills of industrial robots

The application of industrial robots in modern manufacturing is becoming increasingly widespread. They can not only improve production efficiency, reduce labor costs, but also ensure product quality and stability. However, in order to fully utilize the role of industrial...Read more -

How to solve the problem of porosity in robot welds?

Pores in the weld seam are a common quality issue during robot welding. The presence of pores can lead to a decrease in the strength of welds, and even cause cracks and fractures. The main reasons for the formation of pores in robot welds include the following: 1. Poor g...Read more -

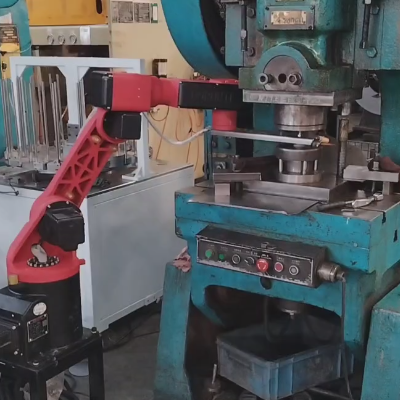

Five common application areas of industrial robots

1、 What is an industrial robot Industrial robots are multifunctional, multi degree of freedom electromechanical integrated automatic mechanical equipment and systems that can complete some operational tasks in the manufacturing process through repeated programming and a...Read more -

What is the general welding speed of robots? What are the technical parameters?

In recent years, with the development of industrial robots, whether robots will replace humans has become one of the hottest topics in this era, especially with the customization of welding robots by industrial robots. It is said that the welding speed of robots is more ...Read more -

What skills and knowledge are required for programming and debugging welding robots?

The programming and debugging of welding robots require the following skills and knowledge: 1. Knowledge related to robot control: Operators need to be familiar with the programming and workflow of welding robots, understand the structure of welding robots, and have expe...Read more -

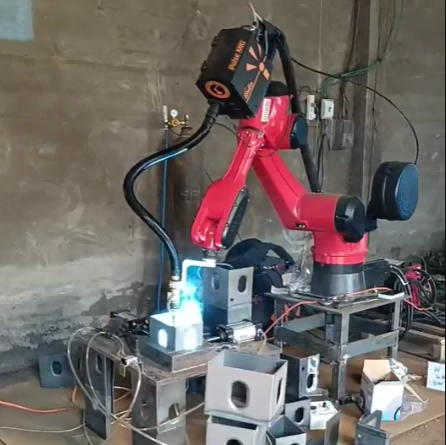

In which industries are welding robots widely used? How to choose a suitable welding robot?

In which industries are welding robots widely used? How to choose a suitable welding robot? Welding robots are widely used in multiple industries, especially in areas with high requirements for production efficiency, product quality, and work environment safety. The foll...Read more -

How to improve the production efficiency of welding robots?

Improving the production efficiency of welding robots involves optimization and improvement in multiple aspects. Here are some key points that can help improve the efficiency of welding robots: 1. Program optimization: Ensure that the welding program is optimized to red...Read more