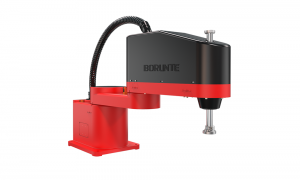

BRTIRPZ2480A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations or operations in dangerous and harsh environments. The maximum arm length is 2411 mm. The maximum load is 80kg. It's flexible with multiple degrees of freedom. Suitable for loading and unloading, handling, dismantling and stacking etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.1 mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

148°/s |

|

|

J2 |

-80°/+40° |

148°/s |

||

|

J3 |

-42°/+60° |

148°/s |

||

|

Wrist |

J4 |

±360° |

296°/s |

|

|

R34 |

70°-145° |

/ |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2411 |

80 |

±0.1 |

5.53 |

685 |

1.Manufacturing business: The industrial palletizing robot arm is widely used in the manufacturing business, where it can automate the palletizing process for a wide range of items, from automotive components to consumer goods. Manufacturers may achieve greater production rates, save labor costs, and assure consistent palletization quality by automating this activity.

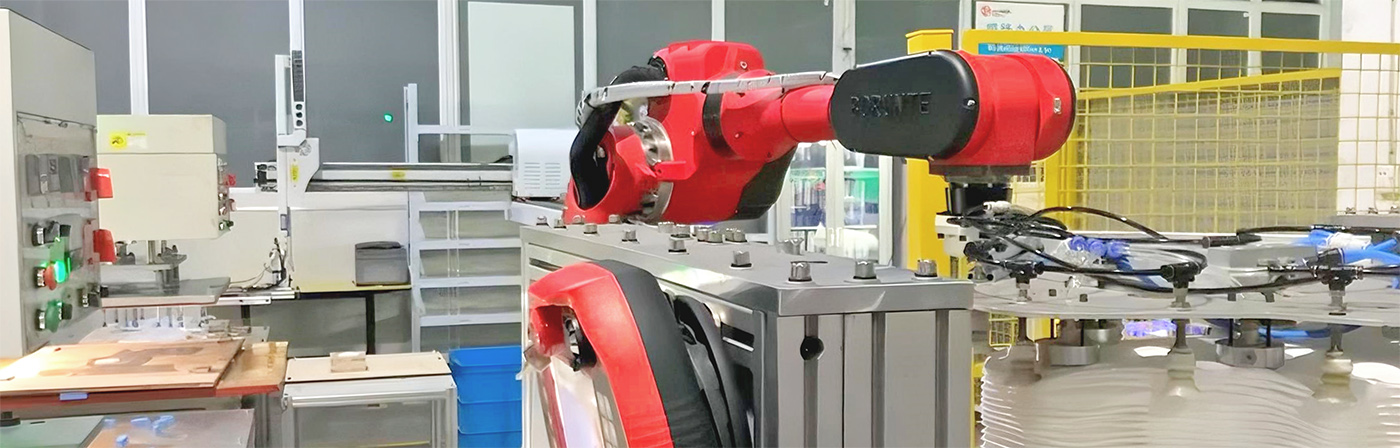

2. Logistics and Warehousing: This robot arm is extremely useful in the warehousing and logistics industries for effectively palletizing and stacking products for storage and transportation. It can handle a broad range of items, such as boxes, bags, and containers, allowing for faster and more precise fulfillment procedures and more customer satisfaction.

3.Food and Beverage sector: The palletizing robot arm is appropriate for applications in the food and beverage sector due to its sanitary design and compliance with industry norms. It is capable of automating the palletization of packaged food, drinks, and other perishable commodities, enabling safe and efficient handling while preserving product integrity and quality.

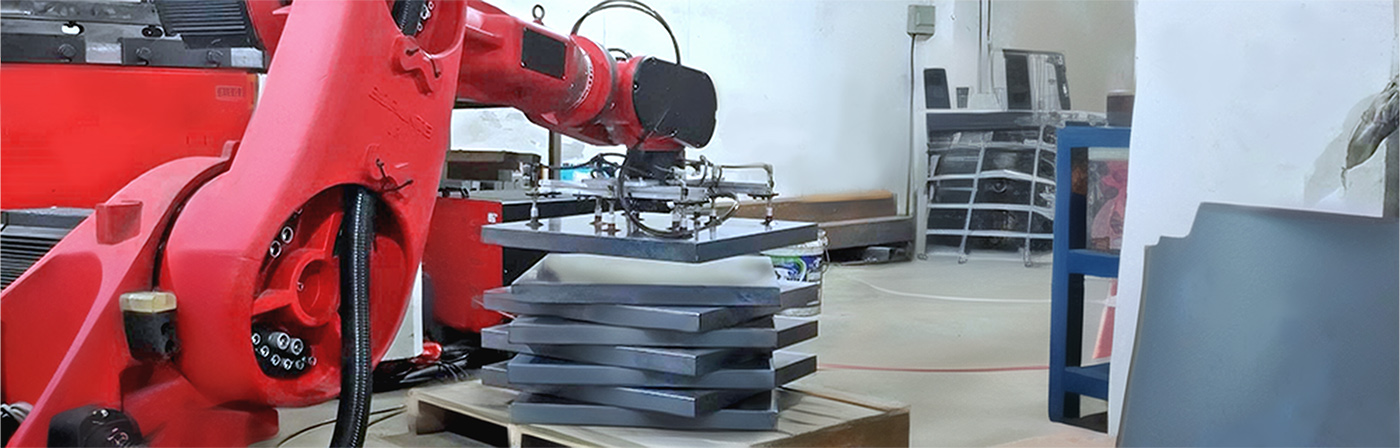

1. Versatile Palletizing: The recently released Industrial Palletizing Robot Arm is a cutting-edge technology developed to automate the palletizing process across many industries. Its extensive features enable it to handle a wide range of items and pallet layouts, making it extremely adaptable for a variety of applications.

2. Large Payload Capacity: This robot arm has a large payload capacity, allowing it to easily lift and stack heavy goods. This robot arm can easily handle huge boxes, bags, and other heavy materials, speeding the palletizing process and decreasing the need for manual labor.

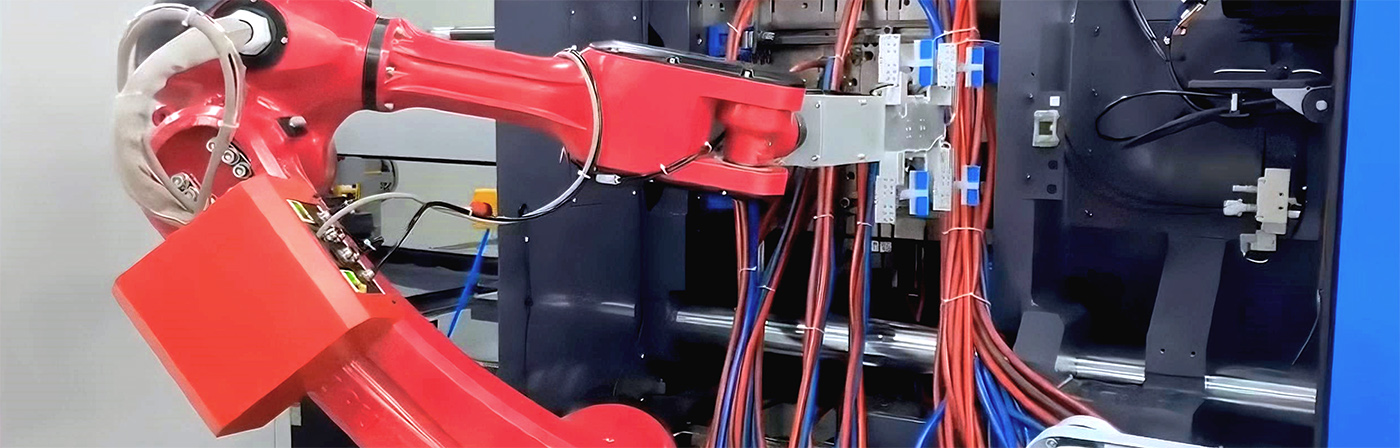

3. Precise and Efficient Operation: Equipped with cutting-edge sensors and sophisticated programming, this palletizing robot arm provides precise and accurate product placement on pallets. It optimizes stacking patterns, increasing space utilization while decreasing the danger of load instability during transit.

4. User-Friendly Interface: The robot arm has a user-friendly interface that allows operators to configure and control its motions effortlessly. Operators can rapidly adjust to utilizing the robot arm thanks to straightforward controls and a visual interface, reducing the learning curve and increasing efficiency.

-

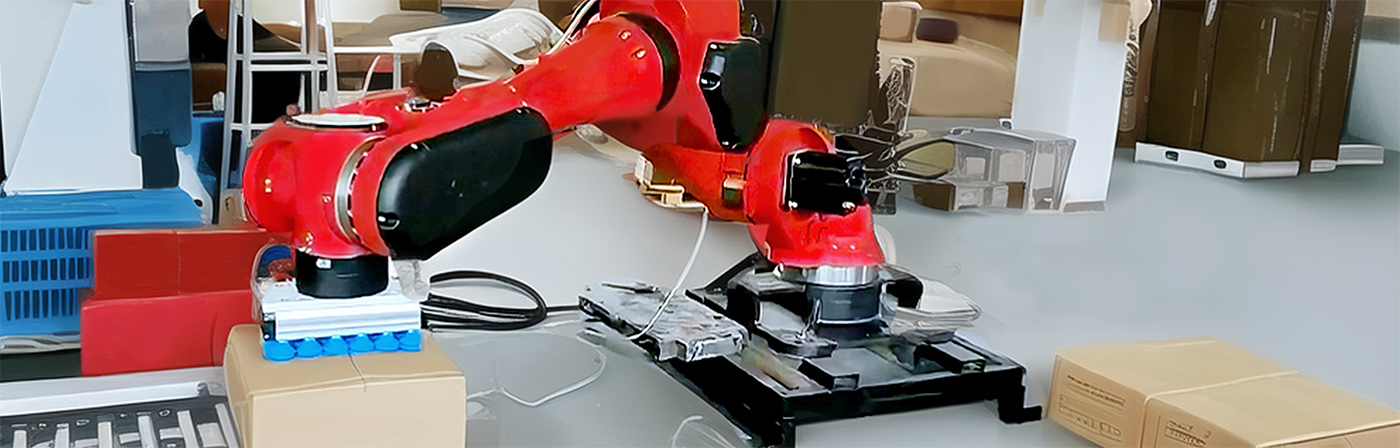

Transport

-

stamping

-

Mold injection

-

stacking

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top