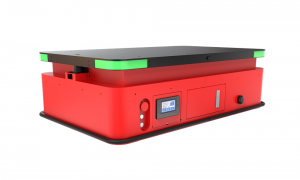

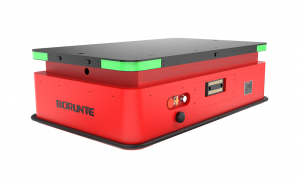

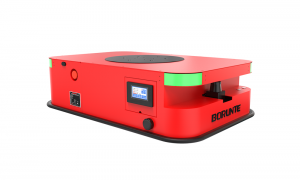

BRTAGV21050A is a composite mobile robot platform using laser SLAM navigation, with a load of 500kg. It can be matched with a low-pressure cooperative robot arm to realize the function of grasping or placing materials, and is suitable for multi site material transmission and grasping. The top of the platform can be equipped with transmission modules of various shapes such as rollers, belts, chains, etc. , to realize the material transfer between multiple production lines, further improve the automation of production processes, and improve production efficiency.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Navigation mode |

Laser SLAM |

|

Driven mode |

Two steering wheel |

|

L*W*H |

1140mm*705mm*372mm |

|

Turning radius |

645mm |

|

Weight |

About 150kg |

|

Rated loading |

500kg |

|

Ground clearance |

17.4mm |

|

Top plate size |

1100mm*666mm |

|

Performance Parameters |

|

|

Trafficability |

≤5% slope |

|

Kinematic accuracy |

±10mm |

|

Cruise Speed |

1m/s(≤1.5m/s) |

|

Battery Parameters |

|

|

Battery parameters |

0.42kVA |

|

Continuous running time |

8H |

|

Charging method |

Manual, Auto, Quick replace |

|

Specific Equipment |

|

|

Laser radar |

✓ |

|

QR code reader |

× |

|

Emergency stop button |

✓ |

|

Speaker |

✓ |

|

Atmosphere lamp |

✓ |

|

Anti-collision strip |

✓ |

Equipment maintenance of BRTAGV21050A:

1. Once a week for the laser and once a month for the steer wheel and universal wheel, respectively. Every three months, the safety labels and buttons must pass a test.

2. Since the robot's driving wheel and universal wheel are composed of polyurethane, they will leave traces on the ground after extended use, necessitating frequent cleaning.

3. The robot body must undergo routine cleaning.

Main features of BRTAGV21050A:

1.A high-capacity battery gives the Composite Mobile Robot Platform a longer operating period. It can be used for eight hours on a single charge, which makes it perfect for usage in big facilities like warehouses, factories, and distribution centers.

2. The Composite Mobile Robot Platform is extremely adaptable and can be utilized in a variety of industries, including logistics, manufacturing, healthcare, hospitality, and retail, thanks to its sophisticated functionality and features. It can be used for jobs like selecting and packaging, managing inventories, ensuring product quality, and even serving as a delivery robot.

3. The Composite Mobile Robot Platform offers significant advantages to the logistics sector. Mobile robots may be used to move products, such as raw materials or completed goods, from one place to another, which will save time and improve productivity. The platform also has autonomous navigation capabilities, allowing it to run with little to no human input and lowering the possibility of workplace mishaps.

-

Warehouse sorting

-

Loading and unloading

-

Automatic handling

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top