BRTIRWD1606A type robot is a six-axis robot that developed by BORUNTE for welding application industry. The robot is compact in shape, small in size and light in weight. Its maximum load is 6kg and its arm span is 1600mm. Wrist hollow structure, more convenient line, more flexible action. The first, second and third joints are equipped with high-precision reducers, and the fourth, fifth and sixth joints are equipped with high-precision gear structures, so the high-speed joint speed can carry out flexible operations. The protection grade reaches IP54. Dust-proof and water-proof. The repeat positioning accuracy is ±0.05mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±165° |

158°/s |

|

|

J2 |

-95°/+70° |

143°/s |

||

|

J3 |

±80° |

228°/s |

||

|

Wrist |

J4 |

±155° |

342°/s |

|

|

J5 |

-130°/+120° |

300°/s |

||

|

J6 |

±360° |

504°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

1600 |

6 |

±0.05 |

6.11 |

157 |

How to choose the industrial welding robot fixtures?

1. Identify the welding process: Determine the specific welding process you'll be using, such as MIG, TIG, or spot welding. Different processes may require different types of fixtures.

2. Understand the work piece specifications: Analyze the dimensions, shape, and material of the work piece that needs to be welded. The fixture must accommodate and securely hold the work piece during welding.

3. Consider welding joint types: Determine the types of joints (e.g., butt joint, lap joint, corner joint) you'll be welding, as this will impact the design and configuration of the fixture.

4. Assess production volume: Consider the production volume and the frequency with which the fixture will be used. For high-volume production, a more durable and automated fixture may be necessary.

5. Evaluate welding accuracy requirements: Determine the level of precision needed for the welding project. Some applications may require tight tolerances, which will influence the fixture's design and construction.

General layout of BRTIRWD1606A

BRTIRWD1606A adopts a six axis joint robot structure, six servo motors drive the rotation of the six joint axes through reducers and gears. It has six degrees of freedom, namely rotation (X), lower arm (Y), upper arm (Z), wrist rotation (U), wrist swing (V), and wrist rotation (W).

BRTIRWD1606A body joint is made of cast aluminum or cast iron, ensuring the high strength, speed, accuracy, and stability of the robot.

-

Spot welding

-

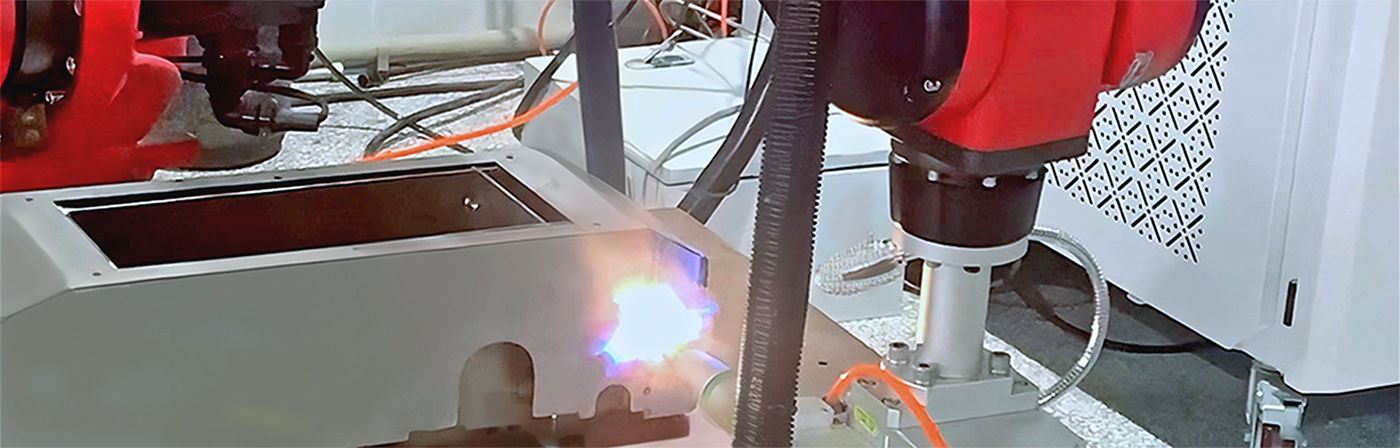

Laser welding

-

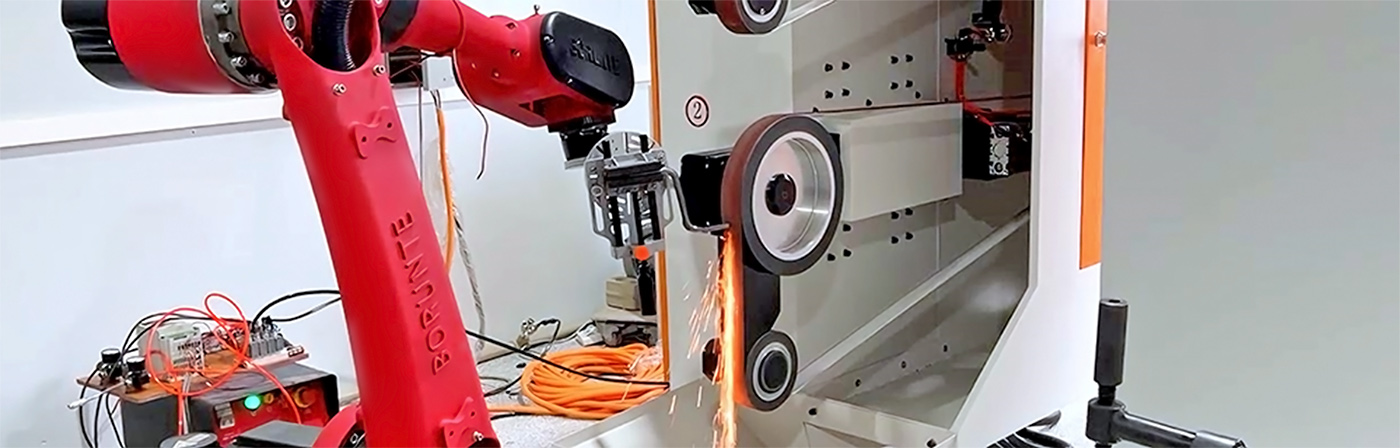

Polishing

-

Cutting

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top