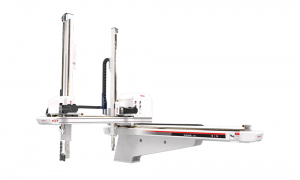

BRTM09IDS5PC/FC series is suitable for the finished product extraction of 160T-320T horizontal injection molding machine, single-cut arm type, two arms, five-axis AC servo drive, can be used for quick removal or in-mold sticking, in-mold inserts and other special product applications. Accurate positioning, high speed, long life, low failure rate. Installing the manipulator can increase production capacity by 10-30% and will reduce the defective rate of products, ensure operator safety, and reduce manual labor. Accurately control production, reduce waste and ensure delivery. Five-axis driver and controller integrated system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, multi-axis can be controlled at the same time, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (kVA) |

Recommended IMM (ton) |

Traverse Driven |

Model Of EOAT |

|

3.1 |

160T-320T |

AC Servo motor |

two suctions four fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max Loading (kg) |

|

1500 |

P:650-R:650 |

900 |

10 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

2.74 |

7.60 |

4 |

310 |

Model representation: I:Single cut type. D: Product arm + runner arm. S5: Five-axis driven by AC Servo Motor( Traverse-axis、Vertical-axis+Crosswise-axis).

The above-mentioned cycle time are the results of our company’s internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

|

1856 |

2275 |

900 |

394 |

1500 |

386.5 |

152.5 |

|

H |

I |

J |

K |

L |

M |

N |

|

189 |

92 |

500 |

650 |

1195 |

290 |

650 |

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

Security issues of BRTM09IDS5PC servo manipulator:

1. the use of manipulator will have less risk of accidental injury to workers.

2. avoid scalding caused by overheating of the product.

3. It is not necessary to enter the mold by hand to take the product, the use of manipulator so as to avoid the potential safety hazard.

4. The manipulator computer is equipped with mold protection. If the product in the mold does not fall off, it will automatically alarm and prompt, and will not damage the mold.

Countermeasures for maintenance safety:

1.The size and number of bolts described in this book must be precisely followed when attaching the accessory components to the end and manipulator. The bolts must be tightened using a torque wrench to the required torque; rusted or dirty bolts must not be utilized.

2. The end fixture should be regulated within the manipulator's permitted load range when it is designed and manufactured.

3. The fault safety protection structure must be used to keep people and machines apart. The gripping object won't be released or fly out even if the power or compressed air source is taken off. In order to protect persons and things, the corner or projecting section must be treated.

The product is appropriate for removing the final product and nozzle from the horizontal injection molding machine 160T-320T. It is ideal for removing common plastic objects in the injection molding industry, such as door MATS, carpets, wires, wall paper, calendar paper, credit cards, slippers, raincoats, plastic steel doors and Windows, leather fabrics, sofas, chairs, and other injection molding products.

-

Injection Molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top