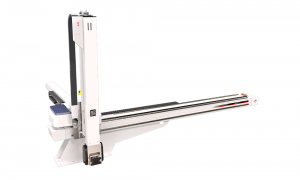

BRTN30WSS5PC/FC is suitable for all types of 2200T-4000T plastic injection molding machines, five-axis AC servo drive, with AC servo axis on the wrist, the rotation angle of the A-axis:360°, and the rotation angle of the C-axis:180°. It can adjust fixtures freely, with long service life, high accuracy, low failure rate, and simple maintenance. It is mainly used for quick injection or complex angle injection. Especially suitable for long shape products such as automotive products, washing machines, and household appliances. Five-axis driver and controller integrated system: fewer signal lines, long-distance communication, good expansion performance, strong anti-interference ability, high accuracy of repeated positioning, can simultaneously control multiple axes, simple equipment maintenance, and low failure rate.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Power Source (kVA) |

Recommended I.M.M (ton) |

Traverse Driven |

Model of EOAT |

|

6.11 |

2200T-4000T |

AC Servo motor |

four suctions two fixtures |

|

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Vertical Stroke (mm) |

Max.loading (kg) |

|

4000 |

2500 |

3000 |

60 |

|

Dry Take Out Time (sec) |

Dry Cycle Time (sec) |

Air Consumption (NI/cycle) |

Weight (kg) |

|

9.05 |

36.5 |

47 |

2020 |

Model representation: W:Telescopic type. S:Product arm. S5:Five-axis driven by AC Servo Motor(Traverse-axis、AC-axis、Vertical-axis+Crosswise-axis).

The above-mentioned cycle time are the results of our company's internal test standard. In the actual application process of the machine, they will vary according to the actual operation.

|

A |

B |

C |

D |

E |

F |

G |

|

2983 |

5333 |

3000 |

610 |

4000 |

/ |

295 |

|

H |

I |

J |

K |

L |

M |

N |

|

/ |

/ |

3150 |

/ |

605.5 |

694.5 |

2500 |

|

O |

||||||

|

2493 |

||||||

No further notice if the specification and appearance are changed due to improvement and other reasons. Thank you for your understanding.

1. The manipulator is extremely safe.

Remove the goods from the mold rather than using personnel to eliminate potential safety dangers such as worker harm in the event of machine failure, incorrect operation, or other crises.

2. Reduce labor costs

Manipulators can replace most human labor, with just a few workers required to oversee the machine's routine functioning.

3. Excellent efficiency and quality

Manipulators are both the manufacturing process and the completed product. They can attain great efficiency and quality while achieving precision that humans cannot.

4. Low rate of rejection

The product has just emerged from the molding machine and has not yet been cooled, therefore there remains residual heat. Hand markings and unequal distortion of items pulled out will result from uneven force of human hands. Manipulators will help to alleviate the problem.

5. Avoid product damage

Mold closure will create mold damage since individuals occasionally neglect to take out the items. If the manipulator does not remove the goods, it will immediately alarm and shut down without causing any damage to the mold.

6.Conserve raw materials and cut expenses

Personnel may remove the goods at an inconvenient period, resulting in shrinkage and distortion of the product. Because the manipulator removes the product at a set time, the quality is consistent.

1. The crane operator should wear a safety helmet, standardize the operation, and pay close attention to safety.

2. During operation, the equipment should be moved away from people in order to avoid passing over their heads.

3. The length of the hanging rope: Bearing: > 1 ton, 3.5-4 meters is acceptable.

-

Injection Molding

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top