BRTIRWD2206A type robot is a six-axis robot developed by BORUNTE for welding application industry. The robot is compact in shape, small in size and light in weight. Its maximum load is 6kg and its arm span is 2200mm. Wrist hollow structure, more convenient line, more flexible action. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.08mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±155° |

106°/s |

|

|

J2 |

-130°/+68° |

135°/s |

||

|

J3 |

-75°/+110° |

128°/s |

||

|

Wrist |

J4 |

±153° |

168°/s |

|

|

J5 |

-130°/+120° |

324°/s |

||

|

J6 |

±360° |

504°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2200 |

6 |

±0.08 |

5.38 |

237 |

How does the arm length influence the welding application?

1.Reach and Workspace: A longer arm allows the robot to access a larger workspace, enabling it to reach distant or complex welding locations without requiring frequent repositioning. This increases efficiency and reduces the need for human intervention.

2.Flexibility: Longer arm length provides greater flexibility, allowing the robot to maneuver and weld around obstacles or in tight spaces, making it suitable for welding complex and irregularly shaped work pieces.

3.Large Work pieces: Longer arms are better suited for welding large work pieces since they can cover more area without repositioning. This is beneficial in industries where large structural components need to be welded.

4.Joint Accessibility: In some welding applications, there are specific angles or joints that can be challenging to access with a short-arm robot. A longer arm can reach and weld these difficult-to-access joints with ease.

5.Stability: Longer arms can sometimes be more prone to vibration and deflection, especially when dealing with heavy payloads or performing high-speed welding. Ensuring adequate rigidity and precision becomes crucial to maintain welding quality.

6.Welding Speed: For certain welding processes, a longer-arm robot might have higher linear speeds due to its larger workspace, potentially increasing productivity by reducing welding cycle times.

The working principle of welding robots:

Welding robots are guided by users and operate step by step according to actual tasks. During the guidance process, the robot automatically remembers the position, posture, motion parameters, welding parameters, etc. of each action taught, and automatically generates a program that continuously executes all operations. After completing the teaching, simply give the robot a start command, and the robot will accurately follow the teaching action, step by step, to complete all operations, actual teaching and reproduction.

-

Spot welding

-

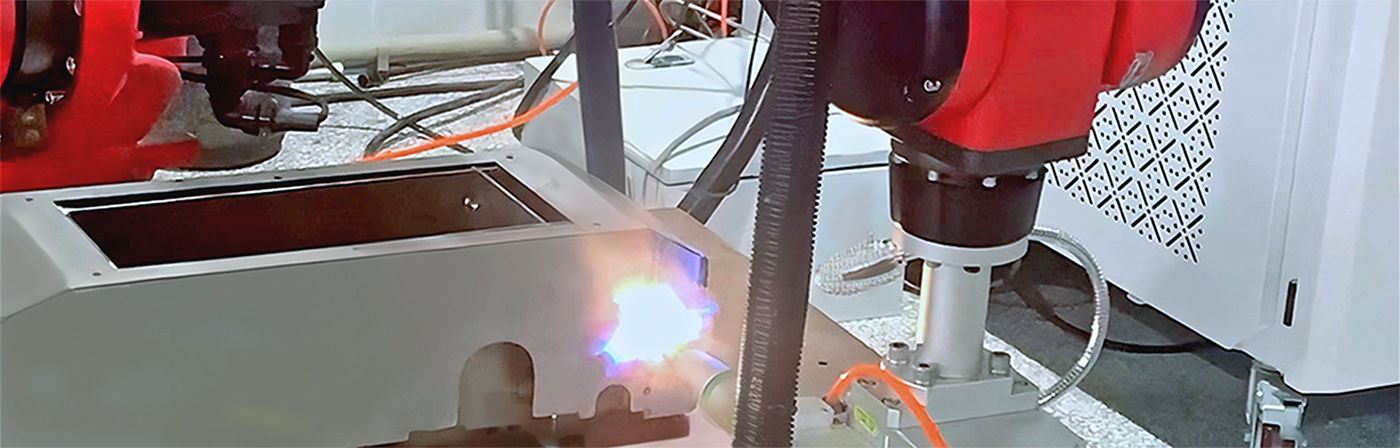

Laser welding

-

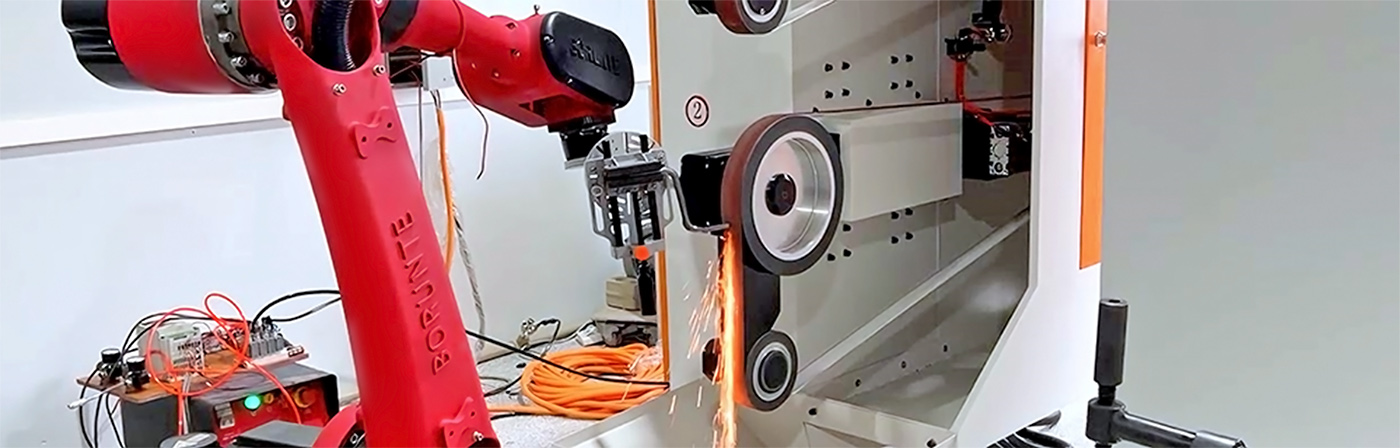

Polishing

-

Cutting

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top