BRTIRUS3050B type robot is a six-axis robot developed by BORUNTE for handling, stacking, loading and unloading and other applications. It has a maximum load of 500KG and a arm span of 3050mm. The shape of the robot is compact, and each joint is equipped with a high-precision reducer. The high-speed joint speed can work flexibly. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.5mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

65.5°/s |

|

|

J2 |

±55° |

51.4°/s |

||

|

J3 |

-55°/+18° |

51.4°/s |

||

|

Wrist |

J4 |

±360° |

99.9°/s |

|

|

J5 |

±110° |

104.7°/s |

||

|

J6 |

±360° |

161.2°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

3050 |

500 |

±0.5 |

43.49 |

3200 |

Features and functions of robot:

1. 500kg load industrial robot has high payload capacity, allowing it to be used with heavy and large payloads.

2. The industrial robot is highly durable and can be used in more challenging environments than typical consumer robotics products.

3. It is designed with advanced motion control capabilities and can be reprogrammed to serve different applications.

4. 500kg load industrial robot can be customized according to customer needs and requirements.

Precautions of changing robot parts When changing the robot components, including updating the system software, it is necessary to be operated by a professional, and the test is performed by a professional to meet the usage requirements before being used again. Non- professionals are prohibited from performing such operations. 5.Confirm the operation under power off.

Turn off the input power first, then disconnect the output and ground cable.

Do not use too much force when disassembling. After replacing the new device, connect the output and ground wire before connecting the input cable.

Finally check the line and confirm before power on to testing.

Note: Some key components may affect the running track after replacement. In this case, you need to find the reason, whether the parameters are not restored, whether the hardware installation meets the requirements, etc. If necessary, you may need to return to the factory for calibration to correction for hardware installation errors.

-

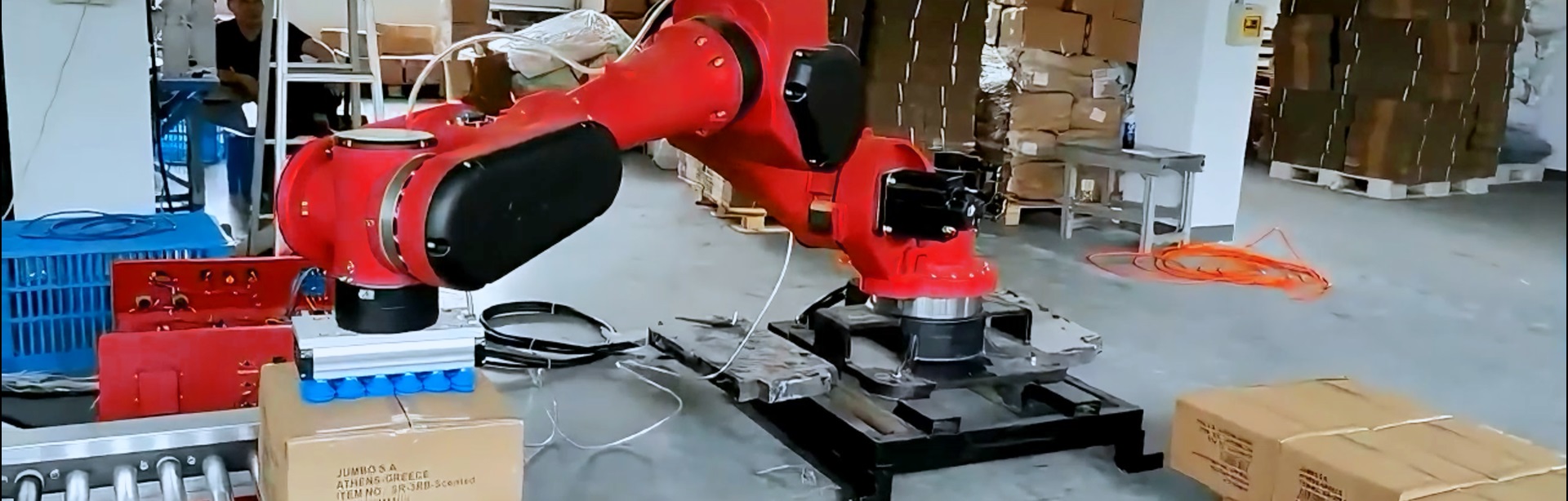

transport

-

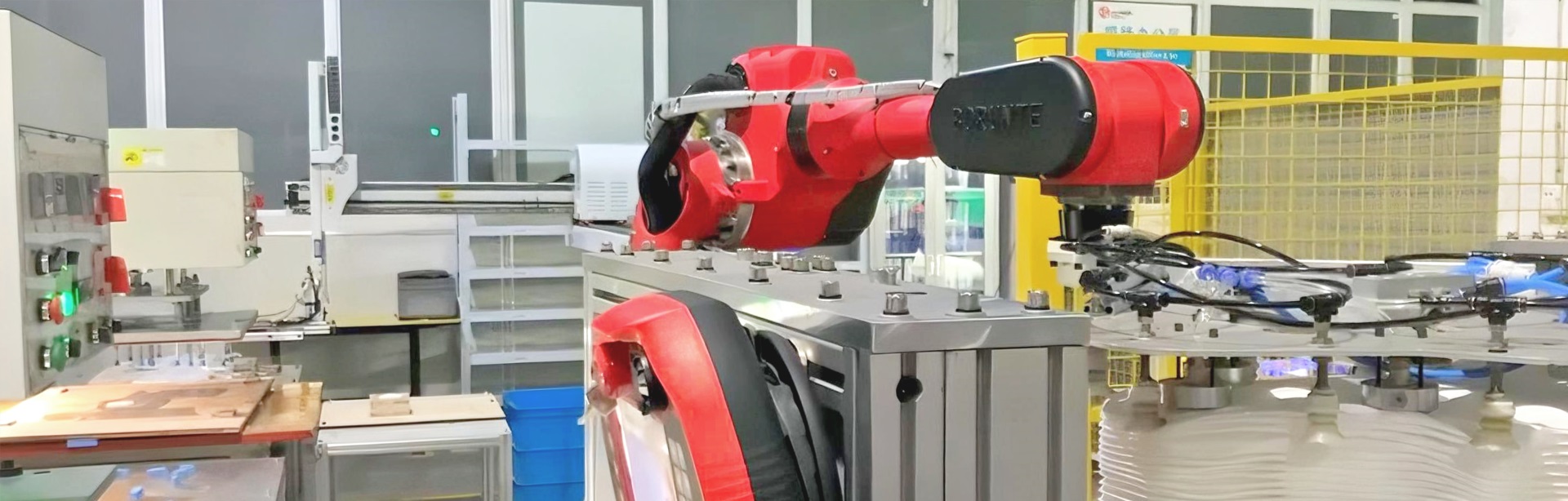

stamping

-

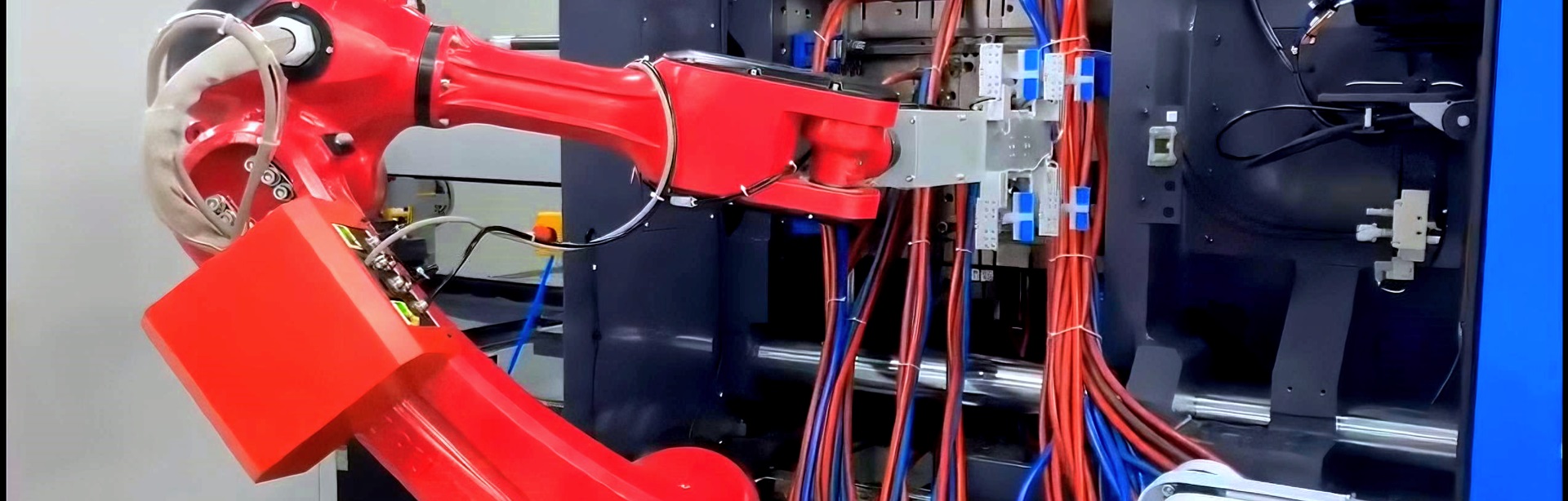

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top