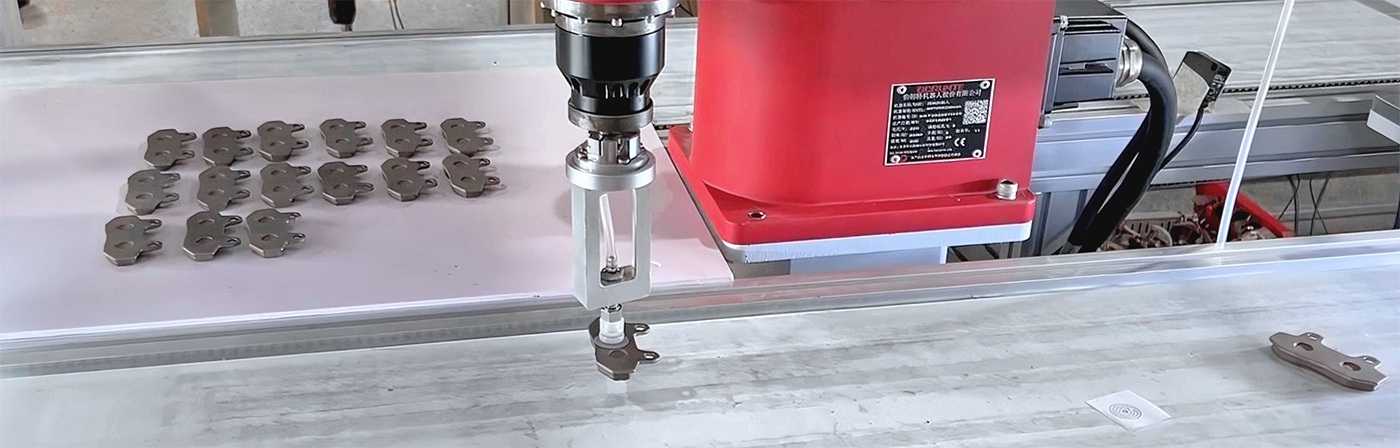

BRTIRSC0603A type robot is a four-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations.The maximum arm length is 600mm. The maximum load is 3kg. It's flexible with multiple degrees of freedom. Suitable for printing and packaging, metal processing, textile home furnishing, electronic equipment, and other fields. The protection grade reaches IP40. The repeat positioning accuracy is ±0.02mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±128° |

480°/s |

|

|

J2 |

±145° |

576°/s |

||

|

J3 |

150mm |

900mm/s |

||

|

Wrist |

J4 |

±360° |

696°/s |

|

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

600 |

3 |

±0.02 |

5.62 |

28 |

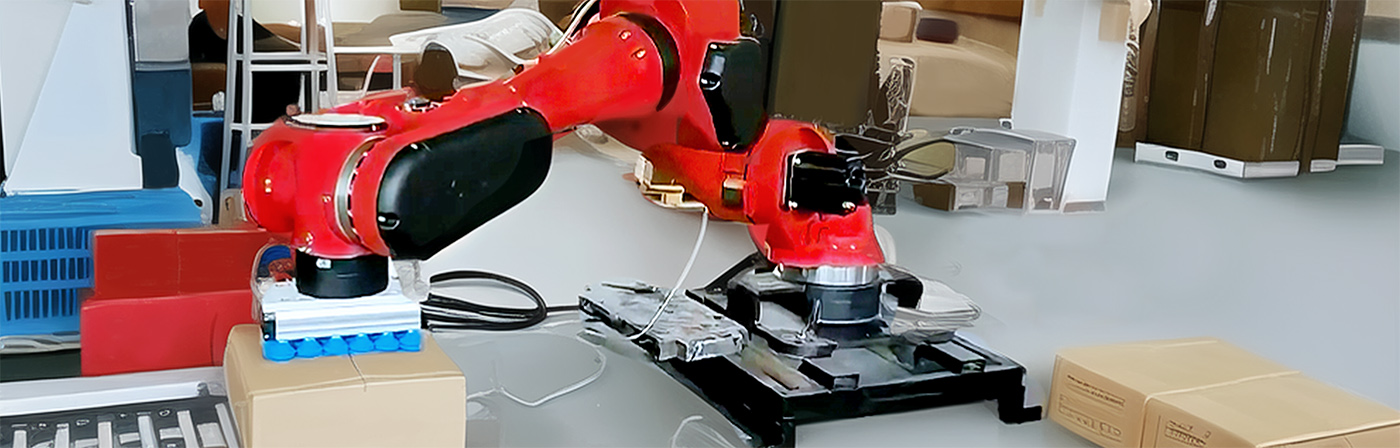

Due to its great precision and speed, the BRTIRSC0603A light weight scara robotic arm is a popular industrial robot utilized in many production operations. It is a common option for manufacturers who want quick and accurate automation solutions for repetitive operations that are challenging for people. The jointed arm of four-axis SCARA robots may move in four directions—X, Y, Z, and rotation around the vertical axis—and is designed to operate on a horizontal plane. Its mobility is based on a synchronized strategy that enables it to do tasks accurately and successfully.

When repairing and replacing the parts of the control cabinet, the following precautions should be observed to ensure safe operation.

1.It is very prohibited for one person to operate the handle adjustment machine while the other is removing components or standing close to the machine. In principle, the machine can only be debugged by one person at a time.

2.The procedure must be carried out at the same potential and with a continuous electrical short circuit between the operator's body (hands) and the control device's "GND terminals".

3.When changing, don't impede the cable that is linked. Avoid contacting any circuits or connections that contain touching components as well as any electrical components on the printed substrate.

4.Maintenance and debugging cannot be transferred to an automated test machine until manual debugging has proven effective.

5.Please don't modify or swap out the original components.

BRTIRSC0603A is a four-axis joint robot with four servo motors driving the rotation of the four joint axes via a reducer and timing belt wheel. It has four degrees of freedom: X for boom rotation, Y for jib rotation, R for end rotation, and Z for end vertical.

The BRTIRSC0603 body joint is built of cast aluminum or cast iron, assuring the machine's great strength, speed, precision, and stability.

-

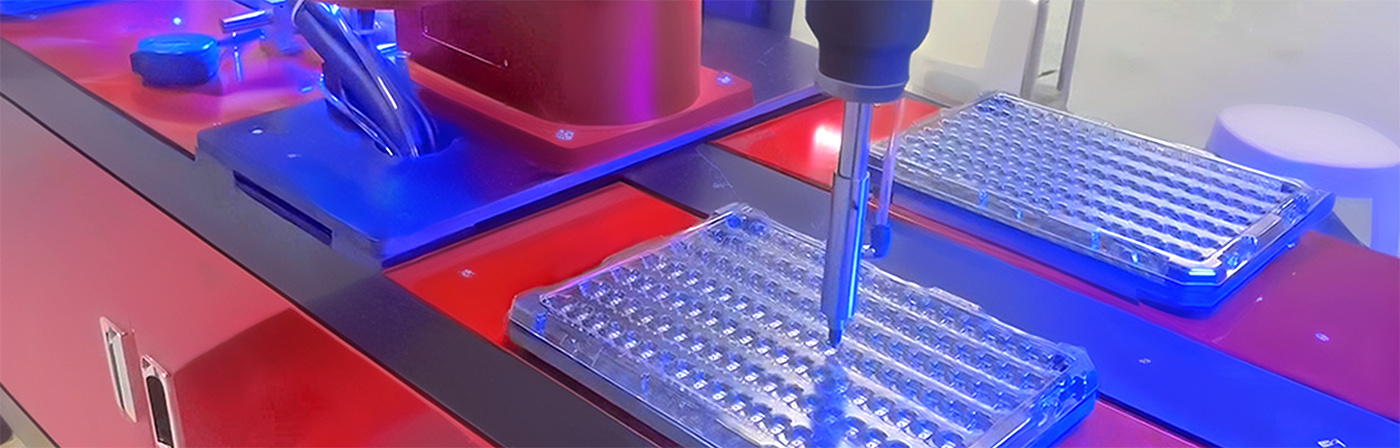

Transport

-

Detection

-

Vision

-

Sorting

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top