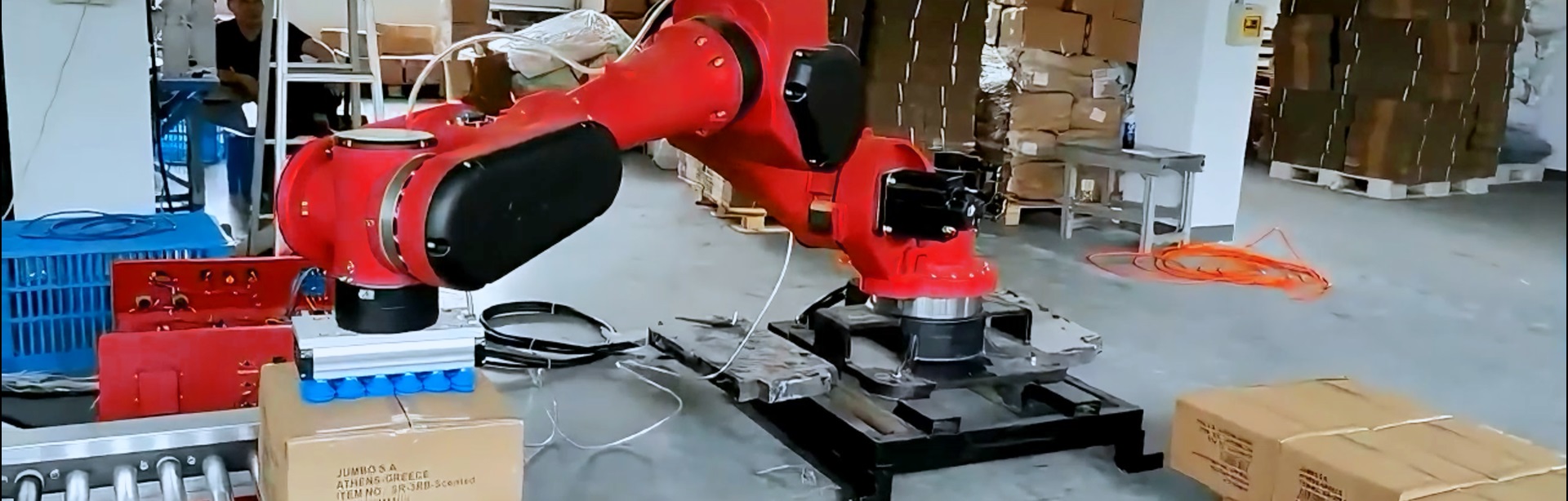

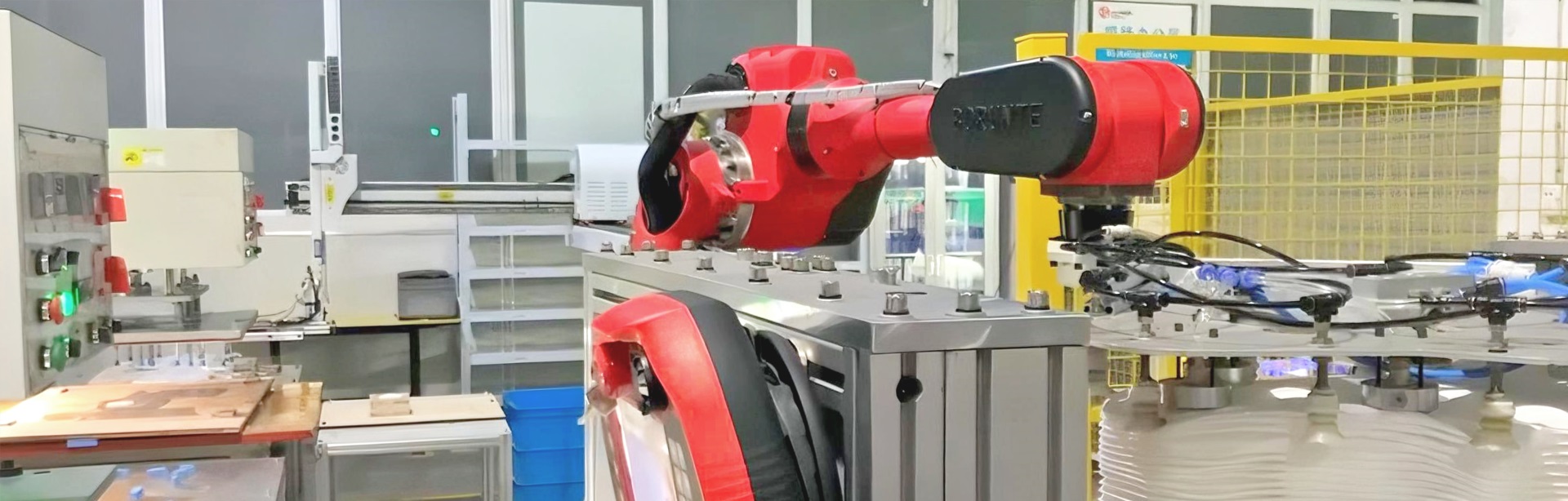

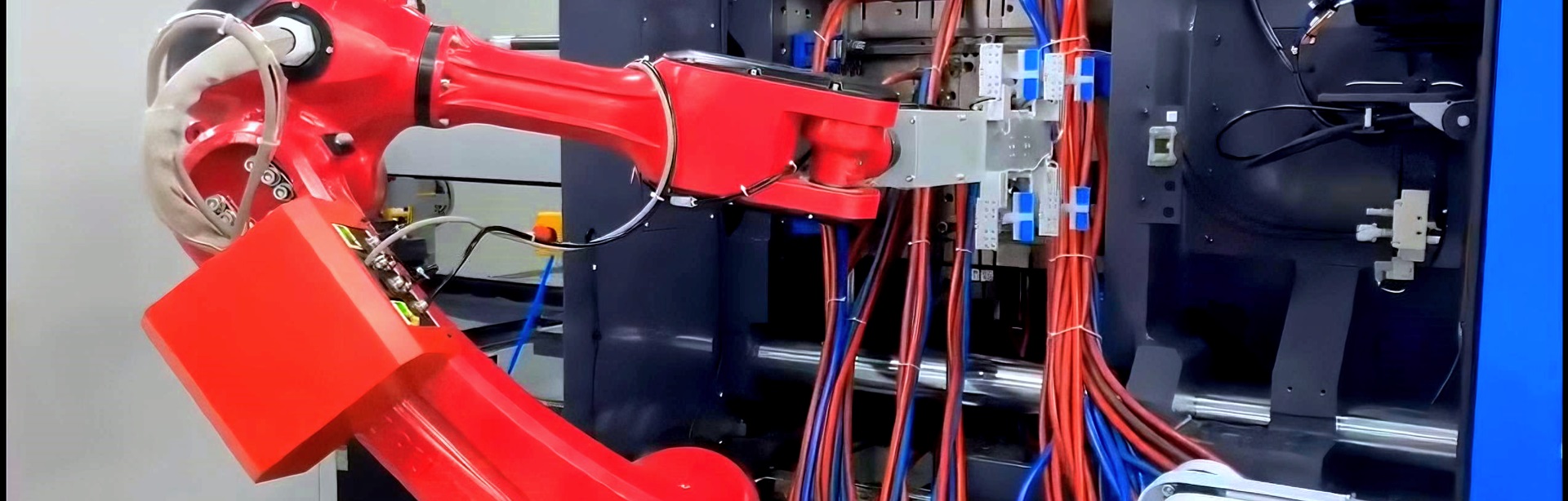

BRTIRUS3511A hom neeg hlau yog 6-axis neeg hlau uas tsim los ntawm BORUNTE rau qee qhov kev ua haujlwm tsis tu ncua, nquag thiab rov ua haujlwm ntev lossis ua haujlwm hauv qhov chaw txaus ntshai thiab hnyav. Qhov siab tshaj plaws caj npab ntev yog 3500mm. Qhov siab tshaj plaws yog 100kg. Nws hloov tau nrog ntau qib ntawm kev ywj pheej. Haum rau kev thauj khoom thiab tshem tawm, tuav, stacking thiab lwm yam. Cov qib tiv thaiv mus txog IP40. Qhov rov ua qhov tseeb yog ± 0.2mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 160 ° | 85 ° / s | |

| J2 | -75 ° / + 30 ° | 70 ° / s | ||

| J3 | -80 ° / + 85 ° | 70 ° / s | ||

| Dab teg | J4 | ± 180 ° | 82 ° / s | |

| J5 | ± 95 ° | 99°/s | ||

| J6 | ± 360 ° | 124 ° / s | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 3500 | 100 | ± 0.2 | 9.71 ib | 1350 |

Peb qhov tseem ceeb ntawm BRTIRUS3511A:

1.Super ntev caj npab ntev muaj neeg hlau tuaj yeem paub qhov tsis siv neeg pub / blanking, workpiece turnover, workpiece sequence transformation of disc, long axis, irregular shape, metal plate and other work pieces.

2.Nws tsis cia siab rau tus maub los ntawm lub tshuab cuab yeej rau kev tswj hwm, thiab tus tswj hwm tau txais kev tswj hwm ywj pheej, uas tsis cuam tshuam rau kev ua haujlwm ntawm lub tshuab cuab yeej.

3. BRTIRUS3511A hom neeg hlau muaj lub caj npab ntev ntev ntawm 3500mm caj npab ntev thiab muaj zog thauj khoom muaj peev xwm ntawm 100kg, uas ua rau nws ua tau raws li ntau yam kev sib tw thiab tuav sijhawm.

1.Thaum lub sijhawm ua haujlwm, qhov kub thiab txias yuav tsum yog li ntawm 0 txog 45 ° C (32 txog 113 ° F) thiab thaum tuav thiab tu, nws yuav tsum nyob ntawm -10 txog 60 ° C (14 txog 140 ° F).

2.Ua rau hauv qhov chaw nrog qhov siab nruab nrab ntawm 0 txog 1000 meters.

3. Qhov txheeb ze av noo yuav tsum tsawg dua 10% thiab qis dua qhov dej lwg.

4. Qhov chaw uas muaj dej tsawg, roj, hmoov av, thiab tsw ntxhiab.

5. Corrosive kua thiab gases nrog rau cov khoom flammable yog tsis tso cai nyob rau hauv lub chaw ua hauj lwm.

6. Cov cheeb tsam uas tus neeg hlau qhov kev vibration lossis cuam tshuam lub zog tsawg (kev vibration tsawg dua 0.5G).

7. Electrostatic paug, qhov chaw ntawm electromagnetic cuam tshuam, thiab cov khoom siv hluav taws xob loj (xws li cov khoom siv roj shielded vuam (TIG)) yuav tsum tsis muaj.

8. Qhov chaw uas tsis muaj kev pheej hmoo ntawm kev sib tsoo nrog forklifts lossis lwm yam khoom txav.

-

thauj

-

stamping

-

Txhaj tshuaj molding

-

Polish

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj