BRTIRWD1506A hom neeg hlau yog 6-axis neeg hlau tsim los ntawm BORUNTE rau txoj kev loj hlob ntawm vuam daim ntawv thov kev lag luam. Cov neeg hlau muaj cov qauv compact, me me ntim thiab lub teeb yuag. Qhov siab tshaj plaws yog 6kg, qhov siab tshaj plaws caj npab ntev yog 1600mm. Lub dab teg siv cov qauv hollow nrog cov kab yooj yim dua thiab hloov tau yooj yim. Qib tiv thaiv mus txog IP54. Dust-proof thiab dej-pov thawj. Qhov rov ua qhov tseeb yog ± 0.05mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 165 ° | 163 ° / s | |

| J2 | -100 ° / + 70 ° | 149°/s | ||

| J3 | ± 80 ° | 223 ° / s | ||

| Dab teg | J4 | ± 150 ° | 169°/s | |

| J5 | ± 110 ° | 270 ° / s | ||

| J6 | ± 360 ° | 398 ° / s | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 1600 | 6 | ± 0.05 hli | 4.64 ib | 166 |

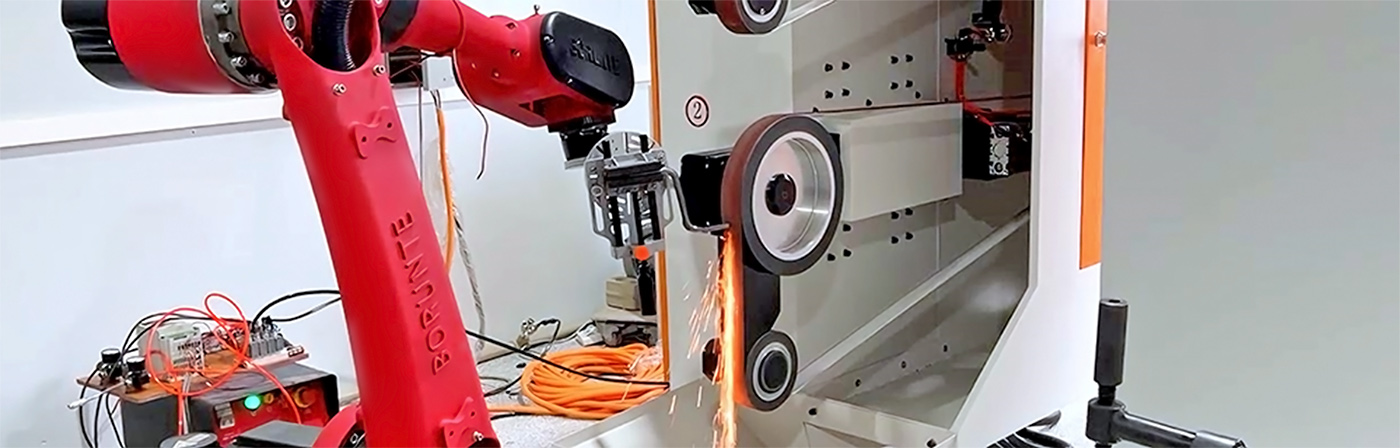

Cov yam ntxwv tseem ceeb ntawm kev siv vuam neeg hlau:

1. Ua kom ruaj khov thiab txhim kho vuam zoo kom ntseeg tau tias nws qhov sib xws.

Siv Robot welding, qhov vuam tsis sib xws rau txhua qhov vuam yog qhov tsis tu ncua, thiab qhov vuam zoo tsis tshua muaj kev cuam tshuam los ntawm tib neeg cov yam ntxwv, txo cov kev xav tau ntawm cov neeg ua haujlwm kev ua haujlwm, yog li qhov vuam zoo yog ruaj khov.

2. Txhim kho kev tsim khoom.

Cov neeg hlau tuaj yeem ua tsis tu ncua 24 teev hauv ib hnub. Tsis tas li ntawd, nrog rau kev siv cov cuab yeej siv hluav taws xob ceev thiab siv tau zoo, kev ua haujlwm ntawm Robot vuam vuam yog txhim kho ntau dua.

3. Clear khoom voj voog, yooj yim los tswj cov khoom tsim tawm.

Cov kev sib dhos ntau lawm ntawm cov neeg hlau yog tsau, yog li cov phiaj xwm ntau lawm yog qhov tseeb heev.

4.Shorten lub voj voog ntawm cov khoom hloov pauv

Yuav ua tiav vuam automation rau cov khoom me me. Qhov sib txawv loj tshaj plaws ntawm cov neeg hlau thiab lub tshuab tshwj xeeb yog tias nws tuaj yeem hloov kho rau kev tsim cov khoom sib txawv los ntawm kev hloov kho qhov kev pab cuam.

-

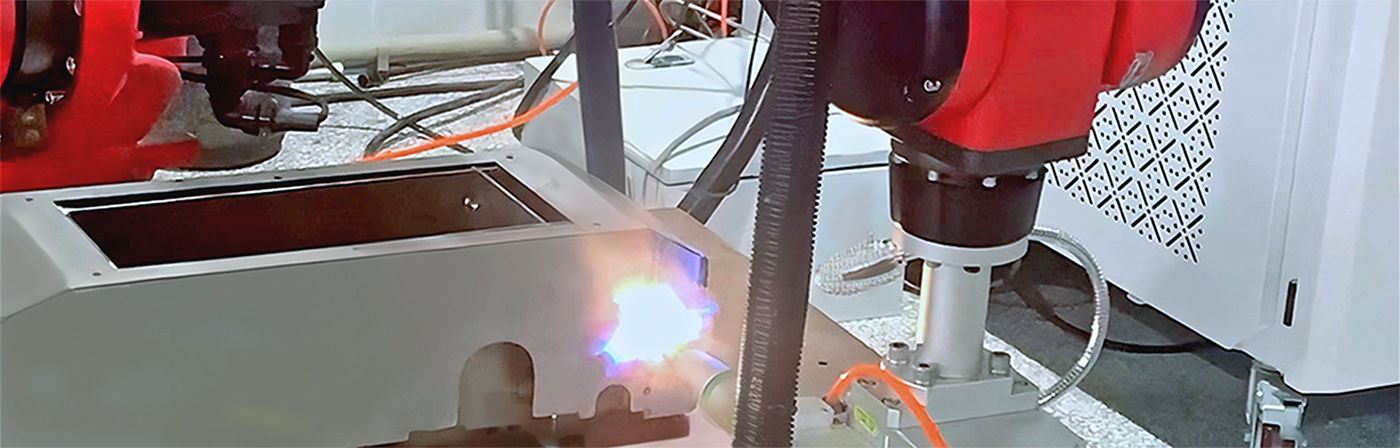

Spot vuam

-

Laser vuam

-

Polishing

-

Txiav

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj