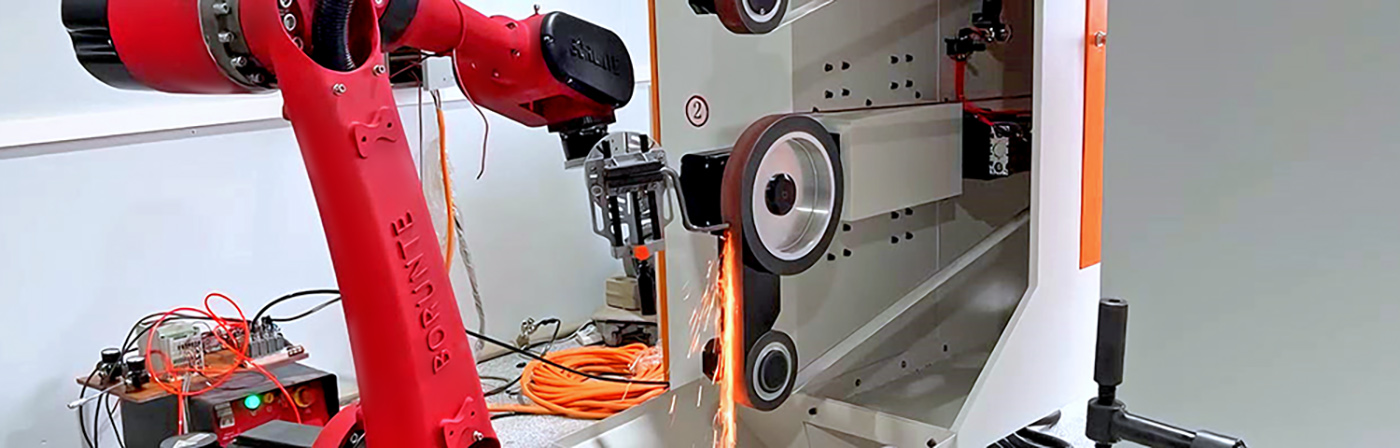

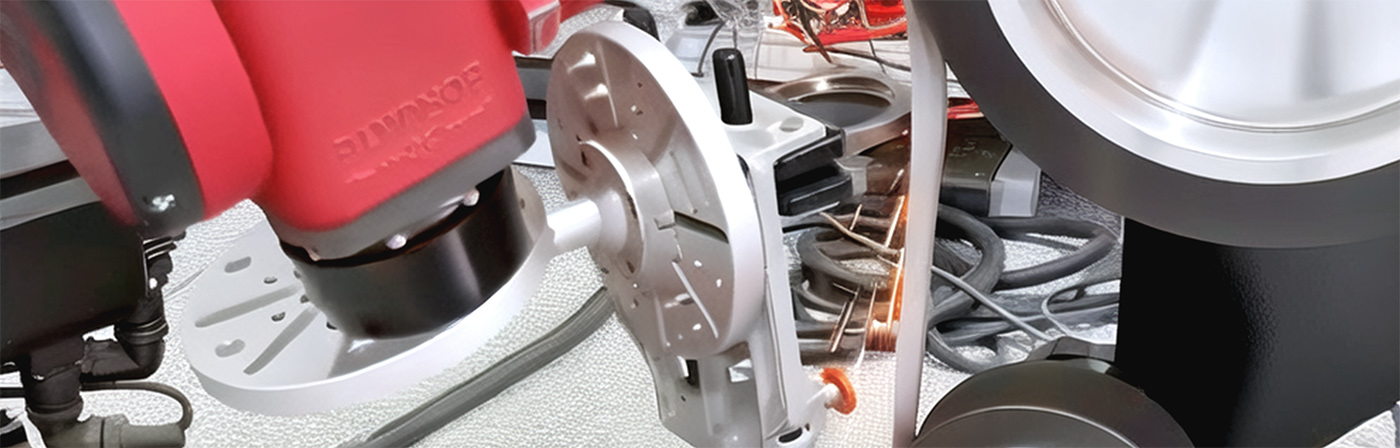

BRTIRPH1210A yog 6-axis neeg hlau tsim los ntawm BORUNTE rau vuam, deburring thiab sib tsoo daim ntawv thov kev lag luam. Nws yog compact nyob rau hauv cov duab, me me nyob rau hauv loj, lub teeb nyob rau hauv hnyav, nrog ib tug siab tshaj plaws load ntawm 10kg thiab ib caj npab ntev ntawm 1225mm. Nws lub dab teg txais cov qauv hollow, uas ua rau cov xaim yooj yim dua thiab txav tau yooj yim dua. Thawj, thib ob thiab thib peb pob qij txha yog tag nrho cov nruab nrog high-precision reducers, thiab plaub, tsib thiab thib rau pob qij txha yog tag nrho cov nruab nrog high-precision iav lug. Kev sib koom ua haujlwm siab ceev ua kom yooj yim ua haujlwm. Qib tiv thaiv mus txog IP54. Dust-proof thiab dej-pov thawj. Qhov rov ua qhov tseeb yog ± 0.07mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 165 ° | 164 ° / s | |

| J2 | -95 ° / + 70 ° | 149°/s | ||

| J3 | ± 80 ° | 185 ° / s | ||

| Dab teg | J4 | ± 155 ° | 384 ° / s | |

| J5 | -130 ° / + 120 ° | 396 ° / s | ||

| J6 | ± 360 ° | 461 ° / s | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

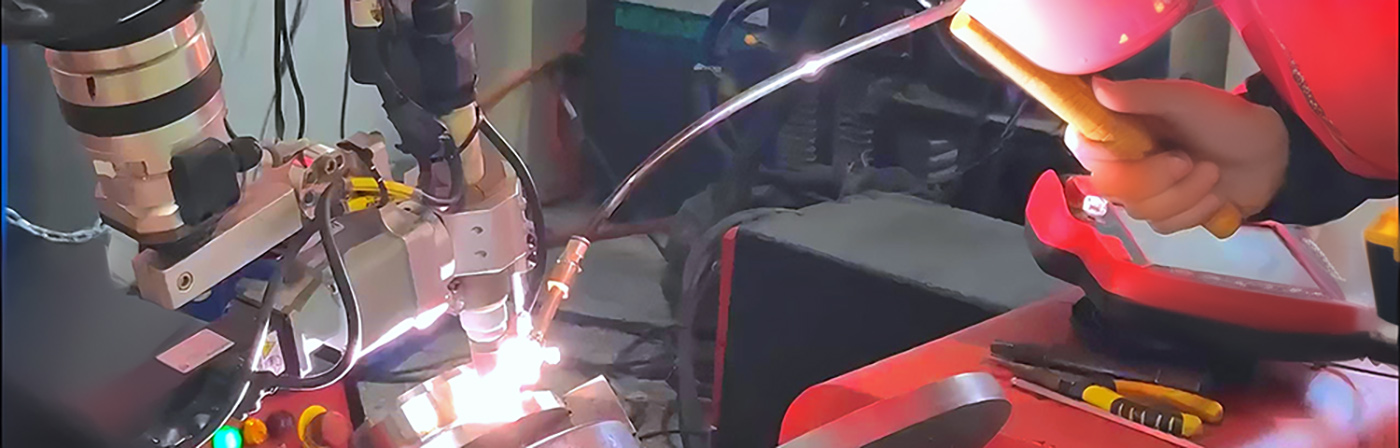

| 1225 | 10 | ± 0.07 hli | 4.30 Nws | 155  1. Dab tsi yog cov txiaj ntsig ntawm kev yuav khoom polishing robotic caj npab? BORUNTE polishing muaj cov neeg hlau tuaj yeem txhim kho kev tsim khoom, txhim kho cov khoom zoo, txo cov nqi zog thiab kev pheej hmoo ntawm tib neeg, nws tuaj yeem ua haujlwm hauv qhov kub thiab txias, cov pa phem thiab lwm qhov chaw ua haujlwm kom muaj kev nyab xeeb dua. 2. Yuav ua li cas xaiv polishing muaj neeg hlau uas haum koj xav tau? Thaum xaiv ib tus neeg hlau, cov hauv qab no yuav tsum tau xav txog: kev ua haujlwm, qhov chaw ua haujlwm, qhov yuav tsum tau muaj tseeb, kev ua haujlwm ceev, kev xav tau kev nyab xeeb, kev ua haujlwm thiab kev ua haujlwm yooj yim, kev tu vaj tse, thiab kev txwv nyiaj txiag. Nyob rau tib lub sijhawm, kev sib tham yuav tsum tau ua nrog cov neeg muab khoom thiab cov kws tshaj lij kom tau txais cov lus qhia ntxaws ntxiv. Cov yam ntxwv tseem ceeb ntawm Professional polishing robotic caj npab: 1. Precision thiab repeatability: Polishing ua hauj lwm feem ntau yuav tsum tau muaj meej meej txav thiab ua haujlwm zoo ib yam. Cov neeg hlau muaj peev xwm tuaj yeem ua haujlwm thiab tswj nrog millimeter qib raug, kom ntseeg tau tias muaj txiaj ntsig zoo hauv txhua qhov haujlwm. 2. Automation thiab efficiency: Ib lub hom phiaj tseem ceeb ntawm kev lag luam robots yog los txhim kho kev tsim khoom. Cov txheej txheem polishing feem ntau yog cumbersome thiab siv sijhawm, tab sis cov neeg hlau tuaj yeem ua haujlwm sai thiab zoo ib yam, yog li kev txhim kho tag nrho cov kev ua haujlwm ntawm cov kab ntau lawm.

Cov khoom qebBORUNTE thiab BORUNTE integratorsHauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

|