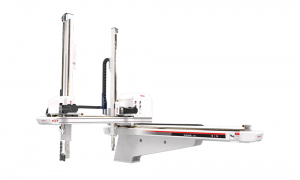

BRTM09IDS5PC / FC series yog tsim rau cov khoom tiav extraction ntawm 160T-320T kab rov tav txhaj molding tshuab, ib leeg-txiav caj npab hom, ob txhais caj npab, tsib-axis AC servo tsav, yuav siv tau rau ceev tshem tawm los yog nyob rau hauv-pwm sticking, nyob rau hauv- pwm inserts thiab lwm yam khoom siv tshwj xeeb. Qhov tseeb qhov chaw, kev kub ceev, lub neej ntev, tus nqi qis qis. Kev txhim kho tus neeg siv khoom tuaj yeem ua kom muaj peev xwm ntau lawm los ntawm 10-30% thiab yuav txo qis tus nqi ntawm cov khoom tsis raug, ua kom cov neeg siv khoom muaj kev nyab xeeb, thiab txo qis kev siv zog. Tswj kev tsim khoom kom raug, txo cov khoom pov tseg thiab xyuas kom cov khoom xa tuaj. Tsib-axis tsav tsheb thiab tswj kev sib xyaw ua ke: tsawg dua cov kab teeb liab, kev sib txuas lus ntev, kev nthuav dav zoo, muaj peev xwm tiv thaiv kev cuam tshuam, muaj qhov tseeb ntawm qhov rov ua dua, ntau lub axis tuaj yeem tswj tau tib lub sijhawm, kev tu cov cuab yeej yooj yim, thiab tsawg tsis ua hauj lwm tus nqi.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Fais fab mov (kVA) | Pom zoo IMM (ton) | Traverse Tsav | Qauv ntawm EOAT |

| 3.1 | 160 T-320 T | AC Servo lub cev muaj zog | ob suctions plaub fixtures |

| Txoj kab uas hla (mm) | Kab rov tav Stroke (mm) | Vertical Stroke (mm) | Max loading (kg) |

| 1500 | P: 650-R: 650 | 900 | 10 |

| Lub Sijhawm Qhuav Qhuav (sec) | Lub Sij Hawm Qhuav (sec) | Kev siv cua (NI / voj voog) | Qhov hnyav (kg) |

| 2.74 ib | 7.60 ib | 4 | 310 |

Tus qauv sawv cev: I: Ib hom kev txiav. D: Khoom caj npab + khiav caj npab. S5: Tsib-axis uas tau tsav los ntawm AC Servo Tsav (Trverse-axis, Vertical-axis + Crosswise-axis).

Lub sijhawm voj voog uas tau hais los saum toj no yog cov txiaj ntsig ntawm peb lub tuam txhab cov qauv ntsuas sab hauv. Nyob rau hauv cov txheej txheem kev thov ntawm lub tshuab, lawv yuav txawv raws li kev ua haujlwm tiag tiag.

| A | B | C | D | E | F | G |

| 1856 | 2275 ib | 900 | 394 ib | 1500 | 386.5 ib | 152.5 ib |

| H | I | J | K | L | M | N |

| 189 | 92 | 500 | 650 | 1195 ib | 290 | 650 |

Tsis muaj kev ceeb toom ntxiv yog tias qhov kev qhia tshwj xeeb thiab cov tsos raug hloov vim yog kev txhim kho thiab lwm yam laj thawj. Ua tsaug rau koj nkag siab.

Kev ruaj ntseg teeb meem ntawm BRTM09IDS5PC servo manipulator:

1. kev siv manipulator yuav muaj kev pheej hmoo tsawg ntawm kev raug mob rau cov neeg ua haujlwm.

2. tsis txhob scalding los ntawm overheating ntawm cov khoom.

3. Nws tsis yog yuav tsum tau nkag mus rau hauv pwm los ntawm txhais tes mus nqa cov khoom, kev siv cov manipulator kom tsis txhob muaj kev phom sij txaus ntshai.

4. Lub tshuab computer manipulator yog nruab nrog kev tiv thaiv pwm. Yog hais tias cov khoom nyob rau hauv pwm tsis poob, nws yuav cia li tswb thiab sai, thiab yuav tsis ua puas pwm.

Countermeasures rau kev ruaj ntseg txij nkawm:

1.Qhov loj thiab tus naj npawb ntawm bolts tau piav nyob rau hauv phau ntawv no yuav tsum tau ua raws li qhov tseeb thaum txuas cov khoom siv rau qhov kawg thiab kev tswj xyuas. Cov bolts yuav tsum tau nruj siv lub torque ciaj ntswj mus rau qhov yuav tsum tau torque; rusted los yog qias neeg bolts yuav tsum tsis txhob siv.

2. Qhov kawg fixture yuav tsum tau tswj nyob rau hauv lub manipulator qhov tso cai load range thaum nws tsim thiab manufactured.

3. Cov qauv kev tiv thaiv kev ruaj ntseg txhaum cai yuav tsum tau siv los ua kom tib neeg thiab tshuab sib nrug. Cov khoom tuav yuav tsis raug tso tawm lossis ya tawm txawm tias lub zog lossis cov cua compressed raug tshem tawm. Txhawm rau tiv thaiv tib neeg thiab khoom, lub kaum sab xis lossis qhov project yuav tsum tau kho.

Cov khoom tsim nyog rau kev tshem tawm cov khoom kawg thiab lub nozzle los ntawm kab rov tav txhaj tshuaj molding tshuab 160T-320T. Nws yog qhov zoo tagnrho rau kev tshem tawm cov khoom siv yas hauv kev txhaj tshuaj molding kev lag luam, xws li lub qhov rooj MATS, ntaub pua plag, xov hlau, phab ntsa ntawv, daim ntawv qhia hnub, credit cards, khau khiab, raincoats, yas steel qhov rooj thiab qhov rais, tawv fabrics, sofas, rooj zaum, thiab lwm yam kev txhaj tshuaj molding khoom.

-

Txhaj Molding

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj