BRTIRWD2206A hom neeg hlau yog 6-axis neeg hlau tsim los ntawm BORUNTE rau vuam daim ntawv thov kev lag luam. Tus neeg hlau yog compact nyob rau hauv cov duab, me me nyob rau hauv loj thiab lub teeb nyob rau hauv qhov hnyav. Nws qhov siab tshaj plaws yog 6kg thiab nws txhais caj npab yog 2200mm. Lub dab teg hollow qauv, kab yooj yim dua, ua haujlwm yooj yim dua. Kev tiv thaiv qib nce mus txog IP54 ntawm lub dab teg thiab IP40 ntawm lub cev. Qhov rov ua qhov tseeb yog ± 0.08mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 155 ° | 106 ° / s | |

| J2 | -130 ° / + 68 ° | 135 ° / s | ||

| J3 | -75 ° / + 110 ° | 128 ° / s | ||

| Dab teg | J4 | ± 153 ° | 168 ° / s | |

| J5 | -130 ° / + 120 ° | 324 ° / s | ||

| J6 | ± 360 ° | 504°/s | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 2200 | 6 | ± 0.08 hli | 5.38 ib | 237 |

Lub caj npab ntev li cas cuam tshuam rau daim ntawv thov vuam?

1.Reach thiab Chaw Ua Haujlwm: Lub caj npab ntev tso cai rau cov neeg hlau nkag mus rau qhov chaw ua haujlwm loj dua, ua kom nws mus txog qhov chaw nyob deb lossis nyuaj vuam yam tsis tas yuav tsum tau hloov chaw ntau zaus. Qhov no ua rau kom muaj txiaj ntsig thiab txo qhov kev xav tau ntawm tib neeg kev cuam tshuam.

2.Flexibility: Ntev caj npab ntev muab kev yooj yim dua, tso cai rau cov neeg hlau ua haujlwm thiab vuam nyob ib puag ncig cov teeb meem lossis hauv qhov chaw nruj, ua rau nws tsim nyog rau vuam txoj haujlwm thiab tsis sib xws ntawm cov khoom ua haujlwm.

3.Large Work pieces: Ntev caj npab yog zoo dua rau vuam loj ua hauj lwm tej daim vim lawv muaj peev xwm npog ntau cheeb tsam yam tsis muaj repositioning. Qhov no muaj txiaj ntsig zoo hauv kev lag luam uas cov khoom siv loj loj yuav tsum tau welded.

4.Koint Accessibility: Hauv qee qhov kev siv vuam, muaj cov kaum ntse ntse tshwj xeeb lossis cov pob qij txha uas tuaj yeem nyuaj rau kev nkag mus nrog cov neeg hlau luv luv. Ib caj npab ntev tuaj yeem ncav cuag thiab txuas cov pob qij txha yooj yim nkag mus tau yooj yim.

5.Stability: Cov caj npab ntev dua tuaj yeem ua rau muaj kev vibration thiab deflection, tshwj xeeb tshaj yog thaum cuam tshuam nrog cov loads hnyav lossis ua haujlwm vuam ceev. Xyuas kom txaus rigidity thiab precision yuav yog ib qho tseem ceeb los tswj cov vuam zoo.

6.Welding Ceev: Rau qee qhov txheej txheem vuam, lub caj npab ntev ntev yuav muaj cov kab nrawm dua vim nws qhov chaw ua haujlwm loj dua, muaj peev xwm ua kom cov khoom tsim tau los ntawm kev txo cov sij hawm vuam voj voog.

Lub hauv paus ntsiab lus ua haujlwm ntawm vuam robots:

Welding robots yog coj los ntawm cov neeg siv thiab ua haujlwm ib kauj ruam raws li cov haujlwm tiag tiag. Thaum lub sij hawm kev taw qhia, tus neeg hlau cia li nco ntsoov txoj hauj lwm, posture, motion parameters, welding tsis, thiab lwm yam ntawm txhua yam uas qhia, thiab cia li generates ib tug kev pab cuam uas tsis tu ncua executes tag nrho cov hauj lwm. Tom qab ua tiav qhov kev qhia, tsuas yog muab cov neeg hlau pib hais kom ua, thiab cov neeg hlau yuav ua raws li kev qhia ua, ib kauj ruam dhau los, ua kom tiav tag nrho cov haujlwm, kev qhia tiag tiag thiab kev tsim tawm.

-

Spot vuam

-

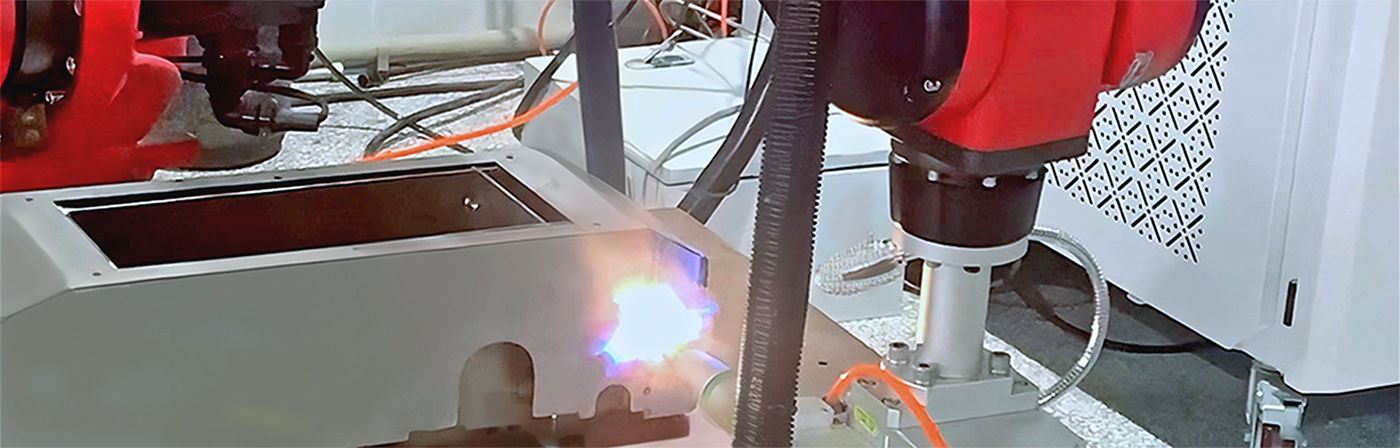

Laser vuam

-

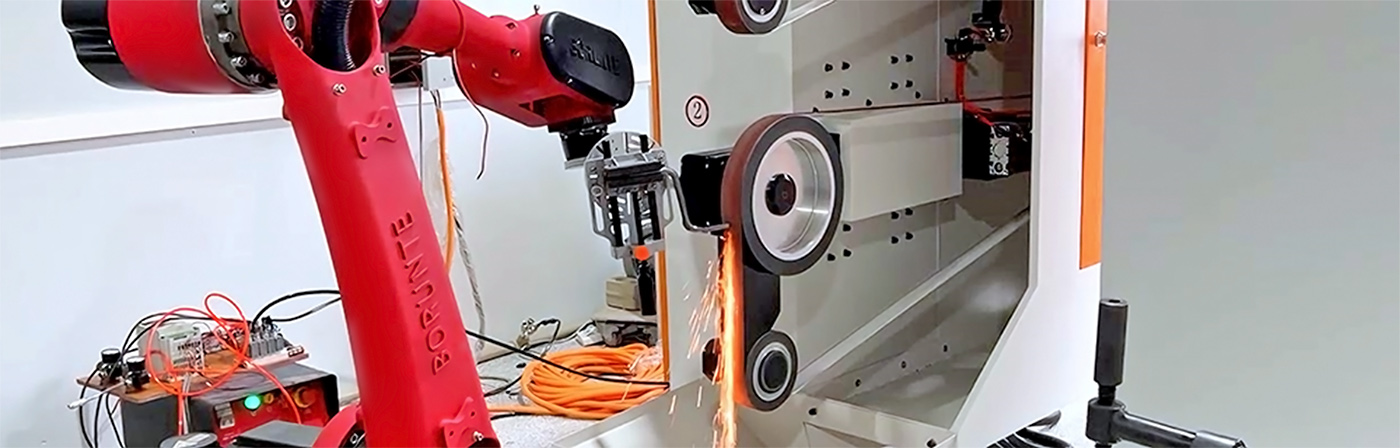

Polishing

-

Txiav

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj