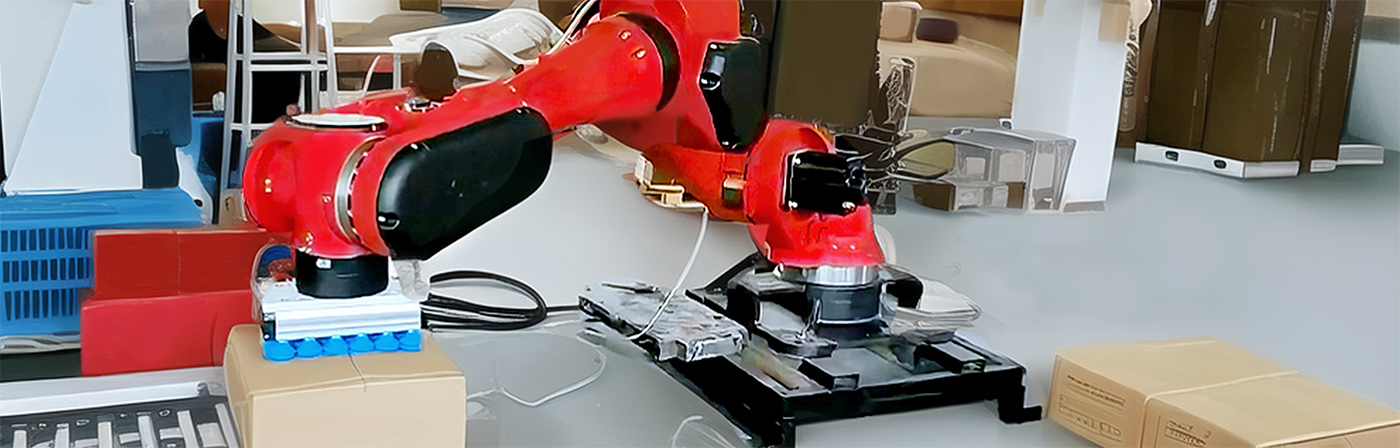

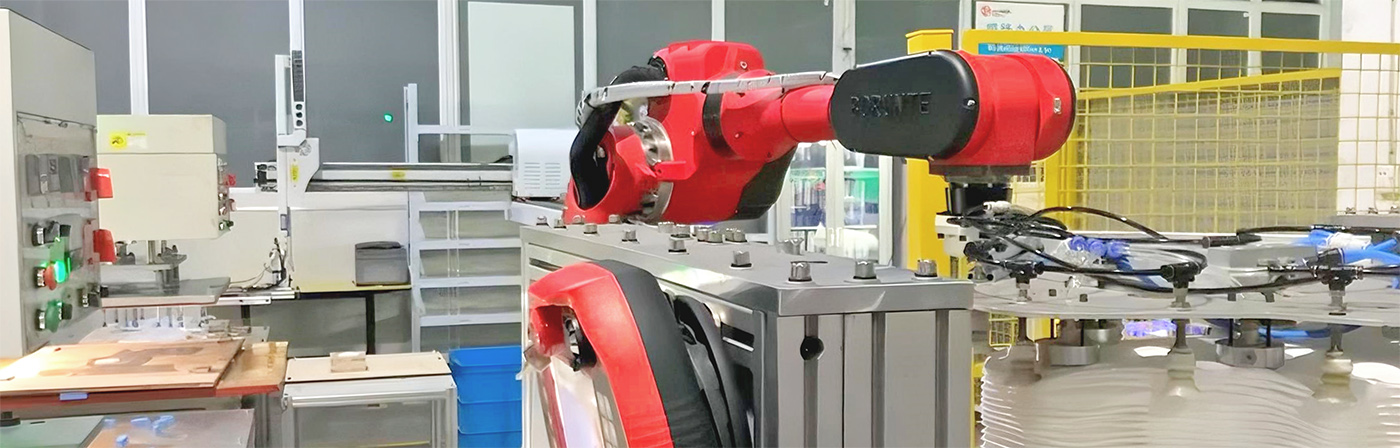

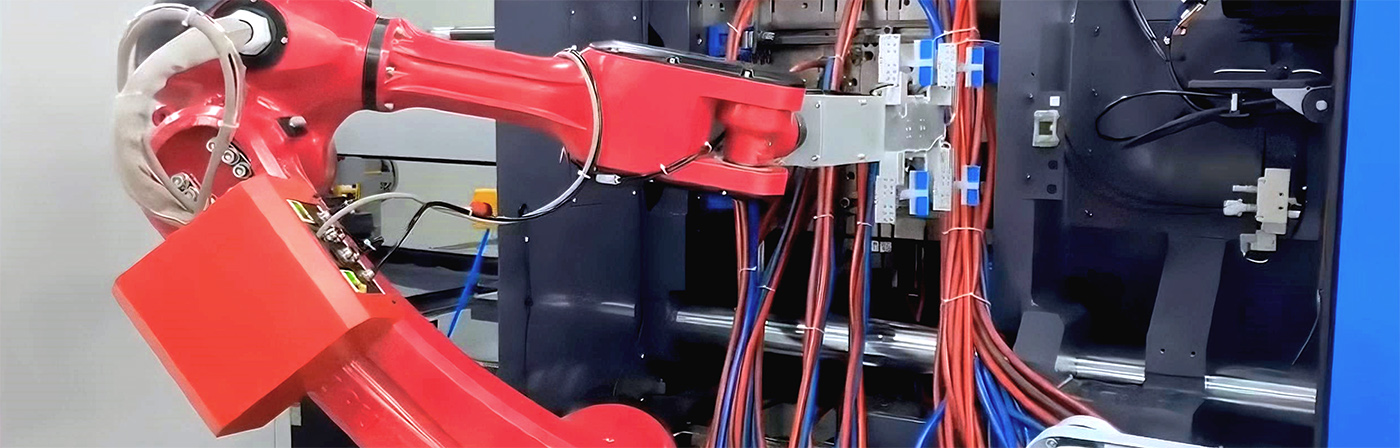

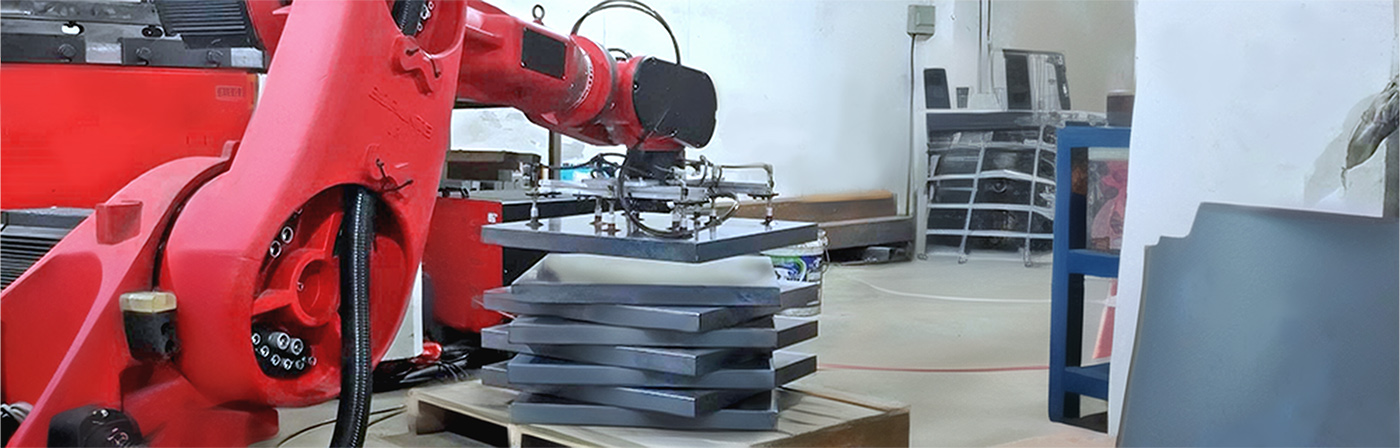

BRTIRPZ1508A hom neeg hlau yog plaub-axis neeg hlau tsim los ntawm BORUNTE, nws siv tag nrho servo lub cev muaj zog tsav nrog cov lus teb ceev thiab qhov tseeb ntawm txoj haujlwm siab. Qhov siab tshaj plaws yog 8kg, qhov siab tshaj plaws caj npab ntev yog 1500mm. Compact qauv ua tiav ntau yam kev txav, yoog raws kev ua kis las, meej. Haum rau qhov chaw txaus ntshai thiab hnyav, xws li stamping, siab casting, kho cua sov, tha xim, yas molding, machining thiab cov txheej txheem sib dhos yooj yim. Thiab nyob rau hauv kev lag luam atomic zog, ua kom tiav kev tuav cov khoom txaus ntshai thiab lwm yam. Nws yog haum rau xuas nrig ntaus. Qib tiv thaiv mus txog IP40. Qhov rov ua qhov tseeb yog ± 0.05mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 160 ° | 219.8 ° / s | |

| J2 | -70 ° / + 23 ° | 222.2 ° / s | ||

| J3 | -70 ° / + 30 ° | 272.7 ° / s | ||

| Dab teg | J4 | ± 360 ° | 412.5 ° / s | |

| R34 | 60 ° -165 ° | / | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 1500 | 8 | ± 0.05 hli | 3.18 | 150  1.Dab tsi yog plaub-axis stacking neeg hlau? Ib tug plaub-axis stacking neeg hlau yog ib hom kev lag luam neeg hlau nrog plaub qib ntawm kev ywj pheej uas yog tsim tshwj xeeb rau cov dej num uas muaj xws li stacking, sorting, los yog stacking khoom nyob rau hauv ntau yam kev siv. 2. Dab tsi yog qhov zoo ntawm kev siv plaub-axis stacking neeg hlau? Plaub-axis stacking neeg hlau muab kev ua haujlwm ntau dua, kev ua tau zoo, thiab sib xws hauv kev sib tsoo thiab kev ua haujlwm. Lawv muaj peev xwm lis ntau yam payloads thiab yog programmable los ua complex stacking qauv. 3. Cov ntawv thov twg yog qhov tsim nyog rau plaub-axis stacking neeg hlau? Cov neeg hlau no feem ntau siv hauv kev lag luam xws li kev tsim khoom, kev xa khoom, khoom noj thiab dej haus, thiab cov khoom siv rau kev ua haujlwm xws li stacking thawv, hnab, cartons, thiab lwm yam khoom. 4. Kuv yuav xaiv txoj cai plaub-axis stacking neeg hlau li cas rau kuv cov kev xav tau? Xav txog yam xws li lub peev xwm thauj khoom, ncav cuag, ceev, raug, muaj chaw ua haujlwm, thiab hom khoom koj xav tau. Ua ib qho kev ntsuam xyuas tag nrho ntawm koj daim ntawv thov yuav tsum tau ua ua ntej xaiv ib tus qauv tshwj xeeb.  1. Siv stacking, ntxig palletizing tsis. ● Ntxig cov txheej txheem qhia, muaj 4 cov lus qhia: kev hloov pauv, npaj ua haujlwm taw tes, stacking point, thiab tawm mus. Thov xa mus rau qhov kev piav qhia ntawm cov lus qhia kom paub meej.  1. Yuav tsum muaj palletizing pawg tsis nyob rau hauv qhov kev pab cuam tam sim no.

Cov khoom qebBORUNTE thiab BORUNTE integratorsHauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

|