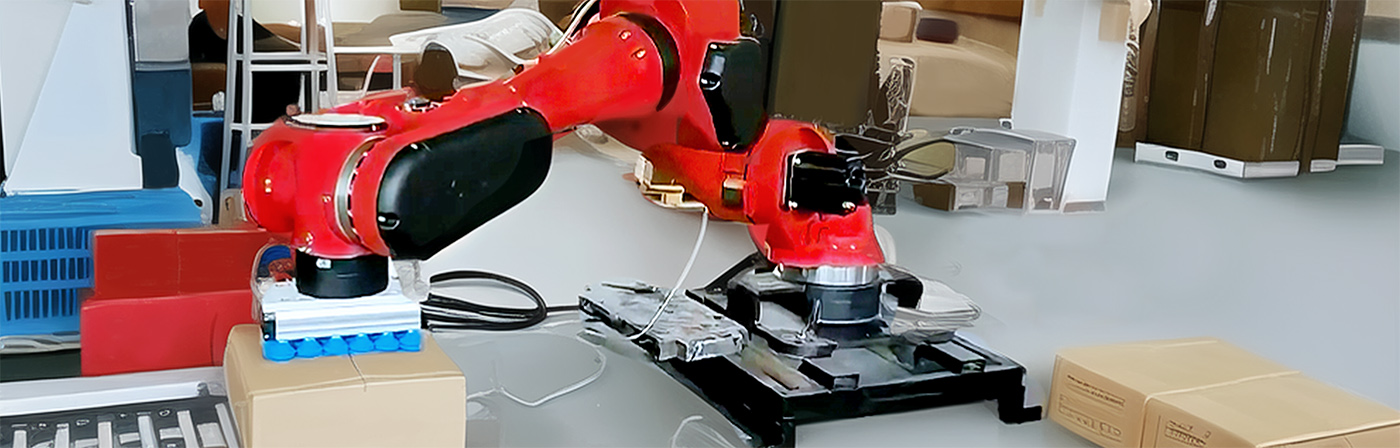

BRTIRPL1003A hom neeg hlau yog plaub-axis neeg hlau uas tsim los ntawm BORUNTE rau kev sib dhos, sorting thiab lwm yam kev thov scenarios ntawm lub teeb, me me thiab cov ntaub ntawv tawg. Qhov siab tshaj plaws caj npab ntev yog 1000mm thiab qhov siab tshaj plaws yog 3kg. Qib tiv thaiv mus txog IP40. Qhov rov ua qhov tseeb yog ± 0.1mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Ntau yam | Max ceev | ||

| Master Arm | Saum toj | Mounting nto rau stroke nrug 872.5mm | 46.7° Nws | Mob stroke: 25/305/25 (mm) | |

| Haum | 86.6° Nws | ||||

| Xaus | J4 | ± 360 ° | 150 lub sijhawm / min | ||

|

| |||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) | |

| 1000 | 3 | ± 0.1 | 3.18 | 104 | |

1.Dab tsi yog plaub-axis parallel neeg hlau?

Ib tug plaub-axis parallel neeg hlau yog ib hom robotic mechanism uas muaj plaub tus kheej tswj cov ceg tawv los yog caj npab txuas rau hauv ib qho kev sib txuas. Nws yog tsim los muab siab precision thiab ceev rau tej daim ntaub ntawv.

2.Dab tsi yog qhov zoo ntawm kev siv plaub-axis parallel neeg hlau?

Plaub-axis parallel robots muaj qhov zoo xws li kev nruj nruj, raug, thiab rov ua dua vim lawv cov kinematics sib npaug. Lawv tsim nyog rau cov dej num uas yuav tsum tau ua kom nrawm nrawm thiab nrawm, xws li kev xaiv thiab chaw ua haujlwm, sib dhos, thiab tuav cov khoom siv.

3.Dab tsi yog cov ntawv thov tseem ceeb ntawm plaub-axis parallel robots?

Plaub-axis parallel robots feem ntau siv hauv kev lag luam xws li kev tsim khoom siv hluav taws xob, tsheb sib dhos, tshuaj, thiab kev ua zaub mov. Lawv ua tau zoo hauv cov dej num xws li kev txheeb xyuas, ntim, gluing, thiab kuaj.

4.Yuav ua li cas lub kinematics ntawm ib tug plaub-axis parallel neeg hlau ua hauj lwm?

Lub kinematics ntawm plaub-axis parallel neeg hlau koom nrog kev txav ntawm nws cov ceg tawv lossis caj npab nyob rau hauv ib qho kev sib piv. Qhov kawg-effector txoj hauj lwm thiab kev taw qhia yog txiav txim siab los ntawm kev sib koom ua ke ntawm cov ceg no, uas yog ua tiav los ntawm kev ua tib zoo tsim thiab tswj algorithms.

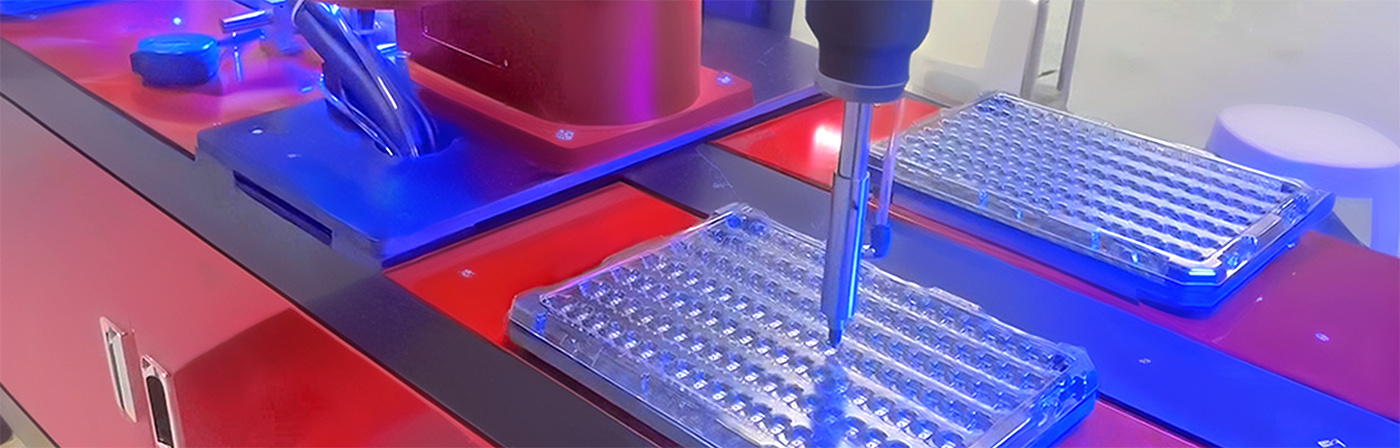

1. Lab Automation:

Plaub-axis parallel robots yog siv nyob rau hauv chaw kuaj mob rau cov dej num xws li tuav cov raj, vials, los yog cov qauv. Lawv qhov tseeb thiab nrawm yog qhov tseem ceeb rau kev ua haujlwm rov ua dua tshiab hauv kev tshawb fawb thiab tshuaj xyuas.

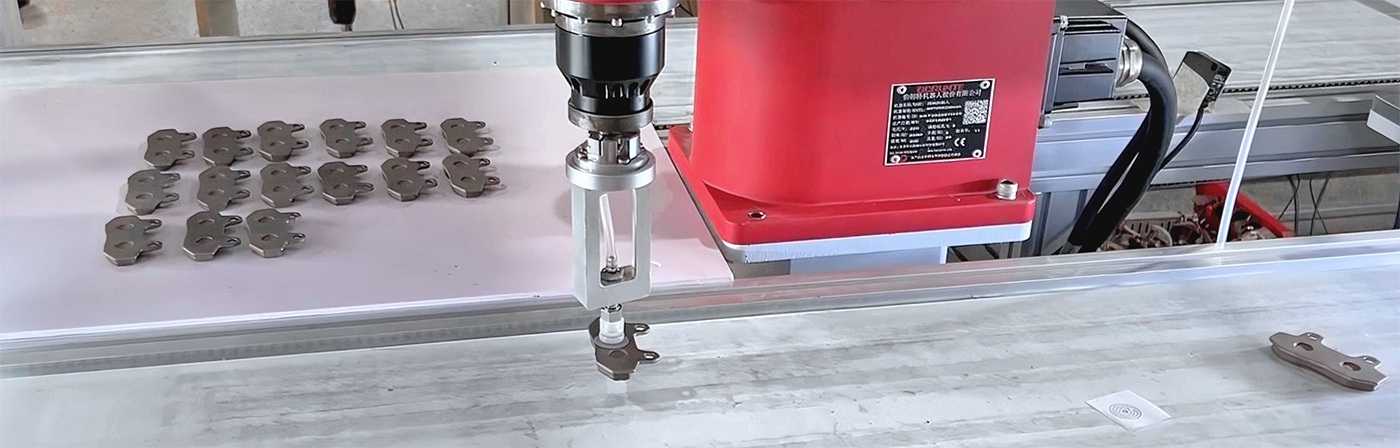

2.Sorting thiab soj ntsuam:

Cov neeg hlau no tuaj yeem ua haujlwm rau hauv cov ntawv sau npe, qhov chaw lawv tuaj yeem xaiv thiab txheeb cov khoom raws li qee yam qauv, xws li qhov loj me, duab, lossis xim. Lawv kuj tuaj yeem ua kev tshuaj xyuas, txheeb xyuas qhov tsis xws lossis tsis sib xws hauv cov khoom.

3.High-Speed Assembly:

Cov neeg hlau no zoo tagnrho rau cov txheej txheem sib dhos ceev, xws li muab cov khoom sib dhos rau hauv lub rooj tsavxwm lossis sib dhos me me. Lawv txoj kev txav ceev thiab raug ua kom muaj kev sib dhos ua haujlwm tau zoo.

4. Ntim:

Hauv kev lag luam xws li cov khoom noj thiab cov khoom siv, plaub-axis parallel robots tuaj yeem ntim cov khoom zoo rau hauv thawv lossis thawv. Lawv cov high-speed thiab raug ua kom cov khoom ntim tau zoo ib yam thiab ua tau zoo.

-

Kev thauj mus los

-

Kev kuaj pom

-

Lub zeem muag

-

Kev txheeb

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj