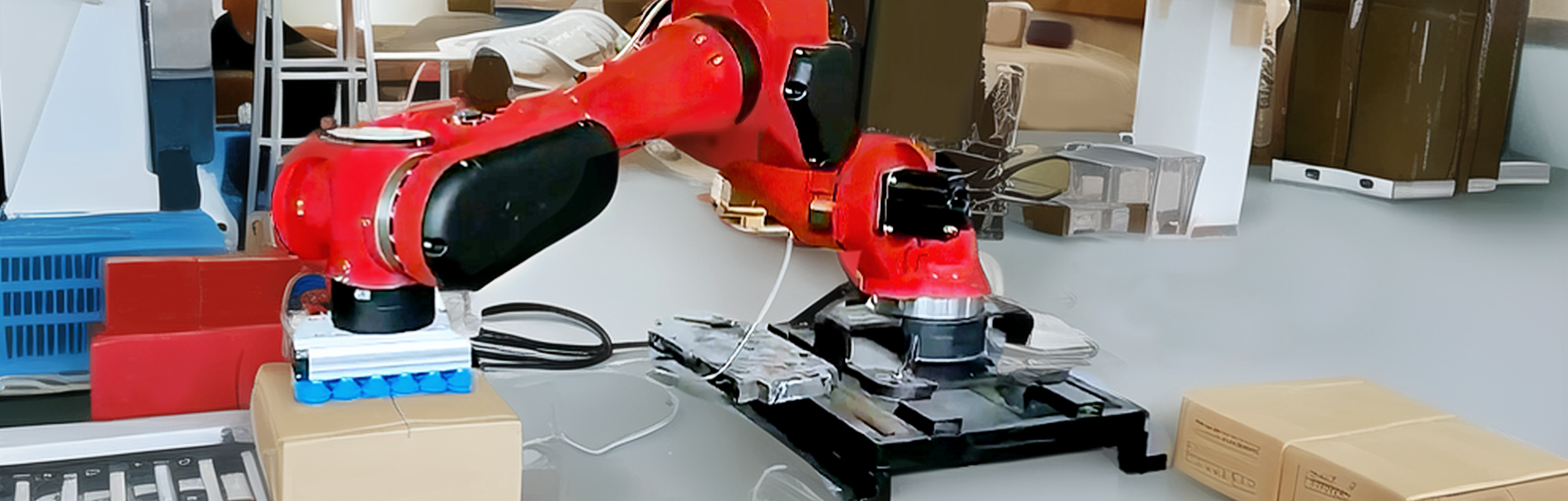

BRTIRPL1608A hom neeg hlau yog plaub-axis neeg hlau uas tsim los ntawm BORUNTE rau kev sib dhos, sorting thiab lwm yam kev thov scenarios ntawm lub teeb, me me thiab tawg cov ntaub ntawv. Qhov siab tshaj plaws caj npab ntev yog 1600mm thiab qhov siab tshaj plaws yog 8KG. Qib tiv thaiv mus txog IP40. Qhov rov ua qhov tseeb yog ± 0.1mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Ntau yam | Max ceev | ||

| Master Arm | Saum toj | Mounting nto rau stroke nrug 1146mm | 38 ° | Mob stroke: 25/305/25 (mm) | |

| Haum | 98 ° | ||||

| Xaus | J4 | ± 360 ° | (Cyclic loading / Rhythm) 0kg / 150time / min, 3kg / 150time / min, 5kg / 130time / min, 8kg / 115time / min | ||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) | |

| 1600 | 8 | ± 0.1 | 6.36 ib | 256 | |

BRTIRPL1608A yog qhov tshwm sim ntawm ntau xyoo ntawm kev tshawb fawb thiab kev loj hlob los ntawm BORUNTE pab pawg ntawm cov kws tshaj lij engineers. Siv lawv cov kev txawj ntse hauv robotics thiab automation, lawv tau kov yeej ntau yam kev sib tw los tsim cov neeg hlau uas ua tau raws li cov kev xav tau ntawm kev lag luam niaj hnub no. Cov txheej txheem kev txhim kho koom nrog kev sim nruj, kev ua kom zoo, thiab kho kom zoo kom ntseeg tau cov qauv siab tshaj plaws ntawm kev ua tau zoo, kev ntseeg siab, thiab kev nyab xeeb.

1. Pick-and-Place:Lub Plaub-Axis Parallel Robot ua tau zoo hauv kev xaiv thiab chaw ua haujlwm, ua haujlwm tau zoo ntawm cov khoom sib txawv thiab cov duab. Nws cov kev taw qhia meej thiab nrawm nrawm ua kom nrawm nrawm, sib dhos, thiab hloov cov khoom, txo qis kev ua haujlwm ntawm phau ntawv thiab txhim kho cov khoom tsim tau.

2. Kev sib dhos: Nrog nws cov high precision thiab versatility, tus neeg hlau no yog ib qho kev xaiv zoo heev rau kev sib dhos ua haujlwm. Nws tuaj yeem ua haujlwm tsis zoo ntawm cov khoom sib txawv, ua kom muaj kev sib raug zoo thiab kev sib raug zoo. Lub Plaub-Axis Parallel Robot txhawb nqa cov txheej txheem sib dhos, ua rau muaj kev tswj xyuas zoo thiab txo lub sijhawm sib dhos.

3. Ntim: Cov neeg hlau ceev ceev thiab meej txav ua rau nws zoo tagnrho rau cov ntawv ntim khoom. Nws tuaj yeem ntim cov khoom sai sai rau hauv lub thawv, cov thawv, lossis cov thawv ntim khoom, kom ntseeg tau qhov chaw zoo ib yam thiab txo qhov ntim cov khoom yuam kev. Four-Axis Parallel Robot optimizes ntim efficiency thiab txhawb nqa ntau lawm.

1. Kuv tuaj yeem koom ua ke Four-Axis Parallel Robot rau hauv kuv cov kab ntau lawm li cas?

BORUNTE muab kev txhawb nqa kev koom ua ke. Peb pab pawg kws tshaj lij yuav ua haujlwm nrog koj kom nkag siab txog koj cov kev xav tau thiab kho cov neeg hlau kev sib koom ua ke kom haum rau koj cov kab ntau lawm. Hu rau peb pab neeg muag khoom kom tau txais kev pab ntxiv.

2. Dab tsi yog qhov siab tshaj plaws payload peev xwm ntawm tus neeg hlau?

Plaub-Axis Parallel Robot muaj lub peev xwm siab tshaj plaws ntawm 8kg, ua kom nws muaj peev xwm ua tau ntau yam khoom thiab cov khoom siv tau zoo.

3. Cov neeg hlau puas tuaj yeem tsim tau los ua cov haujlwm nyuaj?

kiag li! Automatic parallel sorting industrial robots tuaj nrog kev ua haujlwm siab heev. Nws txhawb ntau hom lus programming thiab muab cov neeg siv kev sib raug zoo rau kev ua haujlwm nyuaj nrog yooj yim. Peb pab neeg txhawb nqa kev muaj peev xwm los pab koj hauv kev tsim cov neeg hlau rau koj daim ntawv thov tshwj xeeb.

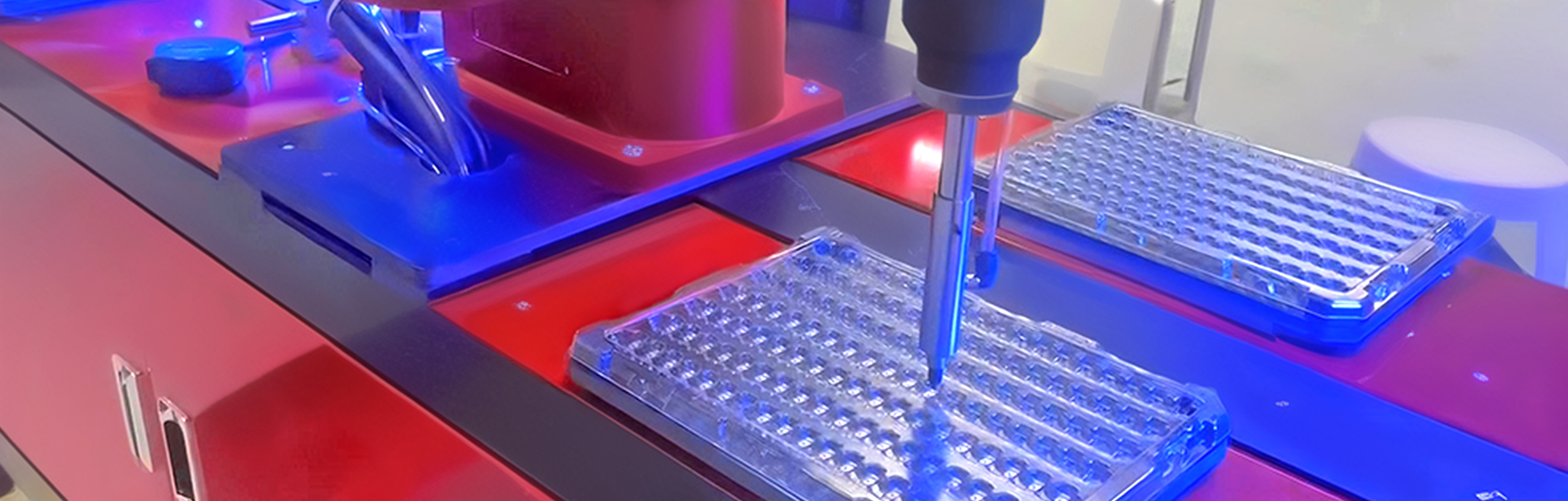

Daim ntawv thov rau Heavy Loading Stacking Robots:

Palletizing, depalletizing, txiav txim xaiv, thiab lwm yam dej num tej zaum yuav ua tau tag nrho los ntawm hnyav loading stacking robots. Lawv muab ib txoj hauv kev los tswj cov khoom loj, thiab lawv tuaj yeem siv los ua kom muaj ntau yam txheej txheem phau ntawv, txo qhov kev thov rau tib neeg kev ua haujlwm thiab kev tsim cov khoom tsim tau. Hnyav loading stacking robots kuj feem ntau siv hauv kev tsim tsheb, kev ua zaub mov thiab dej haus, thiab kev thauj mus los thiab kev faib khoom.

-

Kev thauj mus los

-

Kev txheeb

-

Kev kuaj pom

-

Lub zeem muag

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj