BRTIRPZ1825A hom neeg hlau yog plaub-axis neeg hlau uas tsim los ntawm BORUNTE rau qee qhov kev ua haujlwm tsis tu ncua, nquag thiab rov ua haujlwm ntev lossis ua haujlwm hauv qhov chaw txaus ntshai thiab hnyav. Qhov siab tshaj plaws caj npab ntev yog 1800mm. Qhov siab tshaj plaws yog 25kg. Nws hloov tau nrog ntau qib ntawm kev ywj pheej. Haum rau kev thauj khoom thiab tshem tawm, tuav, dismantling thiab stacking thiab lwm yam. Kev tiv thaiv qib nce mus txog IP40. Qhov rov ua qhov tseeb yog ± 0.08mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 155 ° | 175 ° / s | |

| J2 | -65 ° / + 30 ° | 135 ° / s | ||

| J3 | -62 ° / + 25 ° | 123 ° / s | ||

| Dab teg | J4 | ± 360 ° | 300 ° / s | |

| R34 | 60 ° -170 ° | / | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 1800 | 25 | ± 0.08 hli | 7.33 ib | 256 |

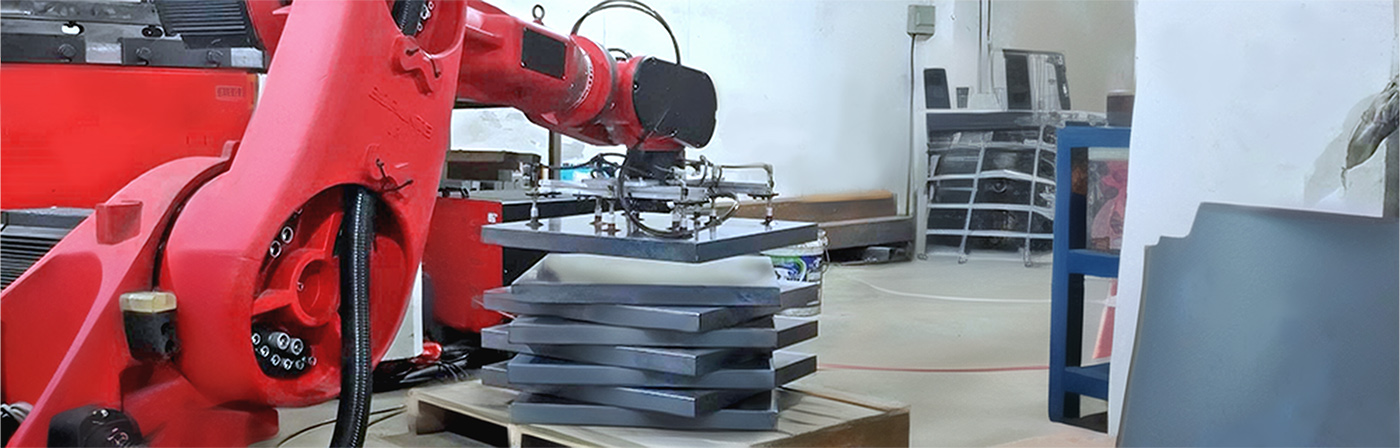

● Ntau qhov chaw trajectory: Qhov siab tshaj plaws caj npab ntev yog 1.8m, thiab qhov hnyav 25kg tuaj yeem haum rau ntau zaus.

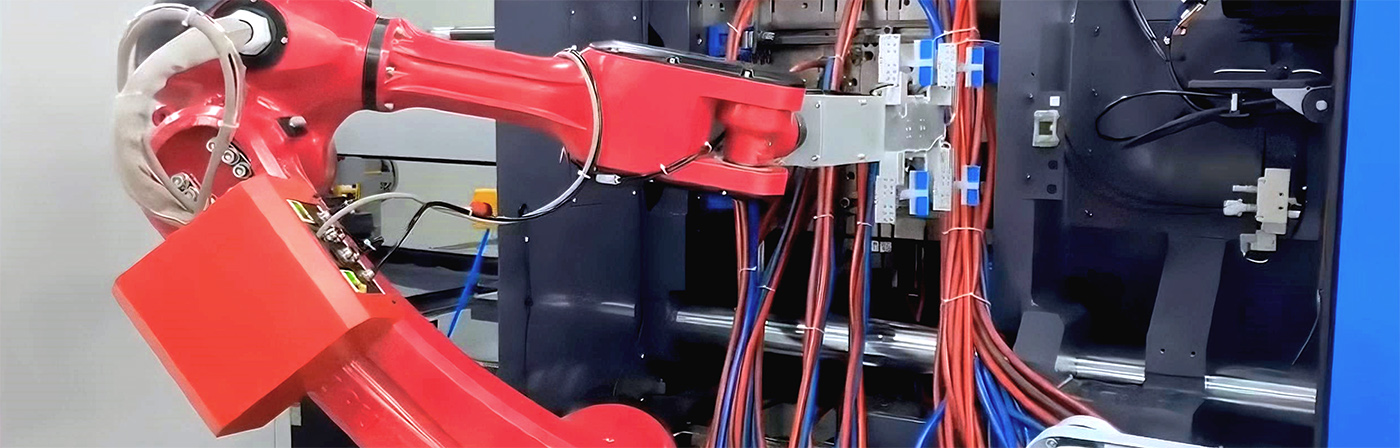

● Diversification ntawm sab nraud interfaces: Sab nraud teeb liab hloov lub thawv neatens thiab nthuav cov teeb liab kev twb kev txuas.

● Lub cev tsim uas yog lub teeb yuag: compact tsim, tsis muaj kev cuam tshuam contour, ua kom lub zog thaum tshem tawm cov qauv tsis tsim nyog thiab txhim kho kev ua haujlwm.

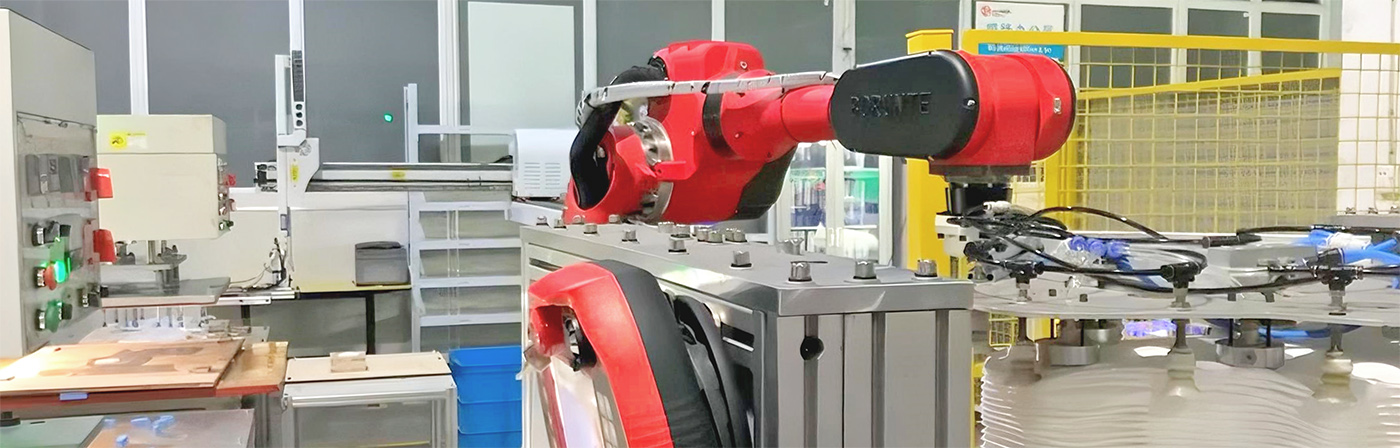

● Kev lag luam ntsig txog: stamping, palletizing, thiab tuav cov khoom nruab nrab.

● high precision thiab ceev: servo lub cev muaj zog thiab high-precision reducer yog siv, ceev teb thiab siab precision

● kev tsim khoom siab: tsis tu ncua 24 teev hauv ib hnub

● txhim kho qhov chaw ua haujlwm: txhim kho kev ua haujlwm ntawm cov neeg ua haujlwm thiab txo cov neeg ua haujlwm hnyav

● cov nqi lag luam: kev nqis peev thaum ntxov, txo cov nqi zog, thiab rov qab cov nqi peev hauv ib nrab xyoo

● Ntau yam: Hardware stamping, teeb pom kev zoo, tableware, khoom siv hauv tsev, tsheb qhov chaw, xov tooj ntawm tes, khoos phis tawj thiab lwm yam lag luam

1. Thov ntsuas qhov concentration ntawm cov hmoov hlau hauv cov roj lubricating ntawm lub gearbox (cov ntsiab lus hlau ≤ 0.015%) txhua 5000 teev ntawm kev ua haujlwm lossis txhua 1 xyoo (

2. Thaum lub sij hawm tu, yog tias ntau tshaj li qhov tsim nyog ntawm cov roj lubricating ntws tawm ntawm lub tshuab lub cev, thov siv rab phom roj lubricating los ntxiv rau qhov tawm. Nyob rau ntawm lub sijhawm no, lub taub hau ntawm lub tshuab roj lubricating siv yuav tsum yog φ Hauv qab 8 hli. Thaum tus nqi ntawm cov roj lubricating ntxiv ntau dua qhov tawm, nws tuaj yeem ua rau lubricating roj to lossis tsis zoo thaum lub sijhawm ua haujlwm neeg hlau, thiab kev saib xyuas yuav tsum tau them.

3. Tom qab kev saib xyuas los yog refueling, txhawm rau tiv thaiv cov roj to, nws yog ib qho tsim nyog yuav tsum qhwv daim kab xev nyob ib ncig ntawm lub lubrication roj yeeb nkab sib txuas thiab lub qhov ntsaws ua ntej kev teeb tsa.

Nws yog ib qho tsim nyog yuav tau siv rab phom roj lubricating nrog cov roj ntshiab kom ntxiv. Thaum nws tsis tuaj yeem npaj cov phom roj nrog cov roj ntshiab uas yuav tsum tau refueled, tus nqi ntawm cov roj yuav tsum tau refueled tuaj yeem paub tseeb los ntawm kev ntsuas qhov kev hloov ntawm qhov hnyav ntawm cov roj lubricating ua ntej thiab tom qab refueling.

-

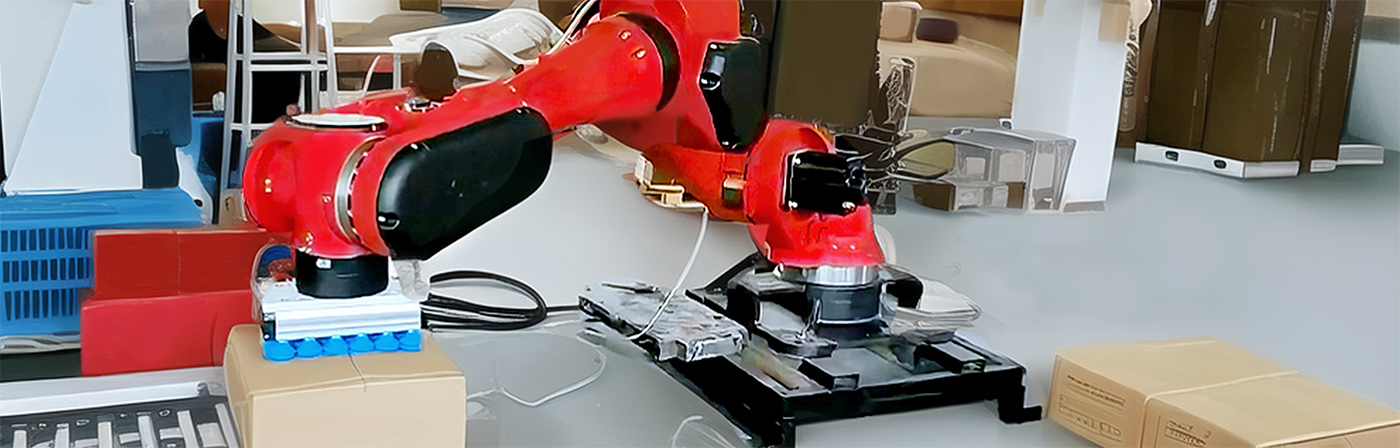

Kev thauj mus los

-

stamping

-

Txhaj tshuaj pwm

-

stacking

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj