BRTIRUS1510A yog 6-axis neeg hlau tsim los ntawm BORUNTE rau kev siv nyuaj nrog ntau qib ntawm kev ywj pheej. Qhov siab tshaj plaws yog 10kg, qhov siab tshaj plaws caj npab ntev yog 1500mm. Lub teeb yuag caj npab tsim, compact thiab yooj yim mechanical qauv, nyob rau hauv lub xeev ntawm kev kub ceev txav, yuav nqa tawm nyob rau hauv ib tug me me chaw ua hauj lwm saj zawg zog ua hauj lwm, ua tau raws li cov kev xav tau ntawm saj zawg zog ntau lawm. Nws muaj rau qib ntawm kev hloov pauv. Haum rau kev pleev xim, vuam, txhaj tshuaj molding, stamping, forging, tuav, loading, assembling, thiab lwm yam. Nws txais HC tswj system, haum rau txhaj tshuaj molding tshuab ntau yam ntawm 200T-600T. Qib tiv thaiv mus txog IP54. Dust-proof thiab dej-pov thawj. Qhov rov ua qhov tseeb yog ± 0.05mm.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Yam khoom | Ntau yam | Max ceev | ||

| Caj npab | J1 | ± 165 ° | 190 ° / s | |

| J2 | -95 ° / + 70 ° | 173 ° / s | ||

| J3 | -85 ° / + 75 ° | 223 ° / s | ||

| Dab teg | J4 | ± 180 ° | 250 ° / s | |

| J5 | ± 115 ° | 270 ° / s | ||

| J6 | ± 360 ° | 336 ° / s | ||

|

| ||||

| Tes Length (mm) | Loading peev (kg) | Repeated Positioning Accuracy (mm) | Fais fab mov (kVA) | Qhov hnyav (kg) |

| 1500 | 10 | ± 0.05 hli | 5.06 ib | 150 |

Daim ntawv thov ntawm BRTIRUS1510A

1. Kev tuav 2. Stamping 3. Txhaj tshuaj molding 4. Sib tsoo 5. Txiav 6. Deburring7. Gluing 8. Stacking 9. Txau, thiab lwm yam.

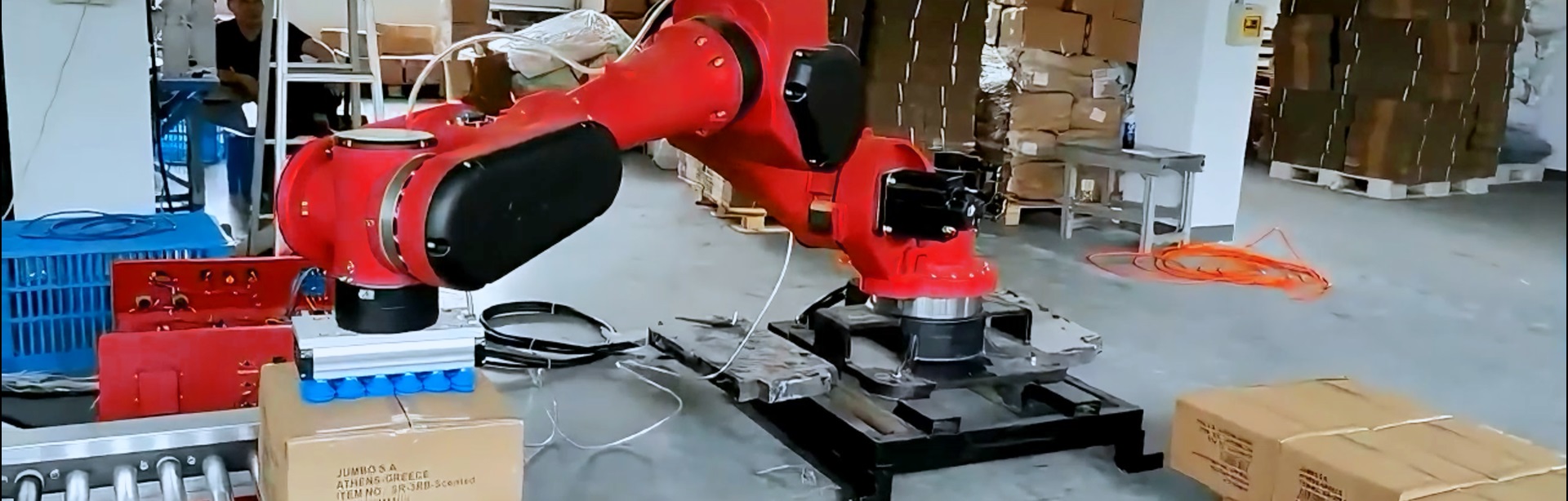

1.Material Handling: Cov neeg hlau tau ua haujlwm los tuav thiab thauj cov khoom hnyav hauv cov chaw tsim khoom thiab cov chaw khaws khoom. Lawv tuaj yeem nqa, pawg, thiab txav cov khoom nrog qhov tseeb, txhim kho kev ua haujlwm thiab txo qhov kev pheej hmoo ntawm kev raug mob hauv chaw ua haujlwm.

2.Welding: Nrog nws cov high precision thiab saj zawg zog, tus neeg hlau yog zoo haum rau vuam daim ntaub ntawv, muab zoo ib yam thiab txhim khu kev qha welds.

3.Spraying: Industrial robots yog siv los pleev xim rau qhov chaw loj hauv kev lag luam xws li tsheb, aerospace, thiab cov khoom siv. Lawv cov kev tswj xyuas meej ua kom muaj qhov sib xws thiab ua tiav zoo.

4.Inspection: Tus neeg hlau qhov kev pom kev ua haujlwm siab tshaj plaws kev sib koom ua ke ua rau nws ua haujlwm zoo, ua kom cov khoom ua tau raws li cov qauv siab tshaj plaws.

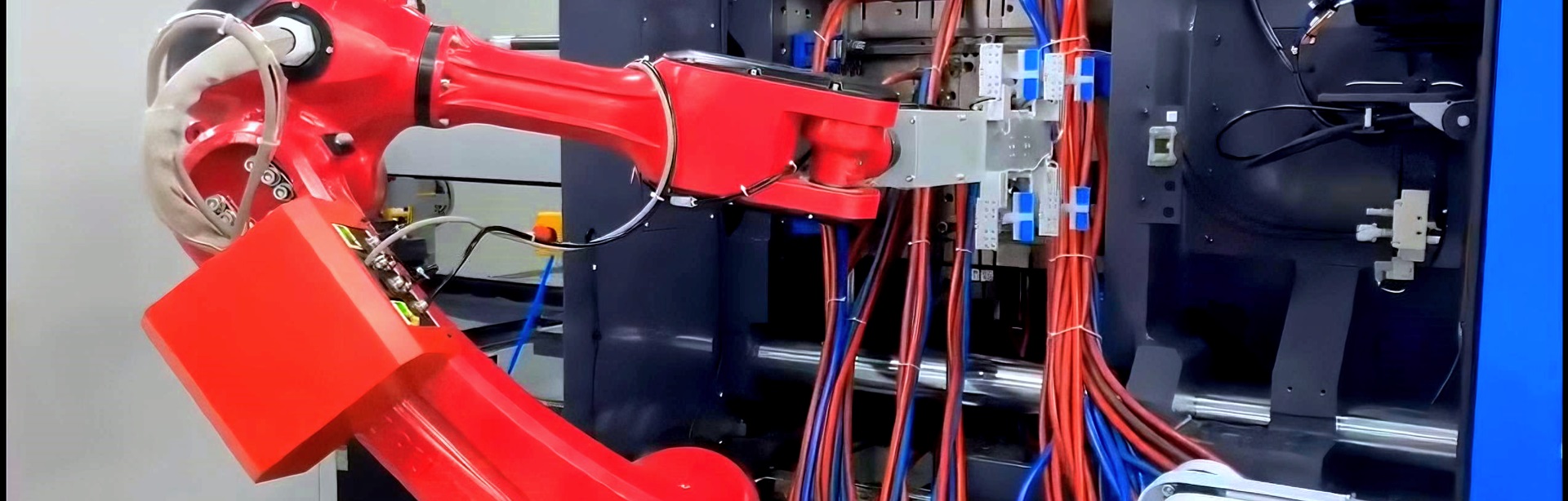

5.CNC Machining: BRTIRUS1510A tuaj yeem ua ke rau hauv Computer Numerical Control (CNC) cov cav tov los ua cov milling nyuaj, txiav, thiab drilling ua haujlwm nrog siab precision thiab repeatability.

Kev tshuaj xyuas neeg hlau ua ntej tawm hauv BORUNTE Hoobkas:

1.Robot yog cov cuab yeej ua haujlwm siab tshaj plaws, thiab nws yog qhov kev zam tsis tau uas yuav tshwm sim thaum lub sijhawm teeb tsa.

2.Txhua tus neeg hlau yuav tsum raug ntsuas ntsuas ntsuas ntsuas ntsuas thiab ntsuas kev them nyiaj kho ua ntej tawm hauv lub hoobkas.

3.Nyob rau hauv qhov tsim nyog raug ntau yam, lub ncej ntev, qhov ceev reducer, eccentricity thiab lwm yam tsis tau them nyiaj los xyuas kom meej cov cuab yeej txav thiab khiav qhov tseeb.

4.Tom qab cov nyiaj calibration yog nyob rau hauv qhov tsim nyog ntau yam (saib lub calibration rooj kom paub meej), yog hais tias cov nyiaj them commissioning tsis nyob rau hauv lub tsim nyog ntau yam, nws yuav raug xa rov qab mus rau cov kab ntau lawm rau kev rov ntsuam xyuas, debugging thiab sib dhos, thiab ces. calibrated kom txog thaum tsim nyog.

-

thauj

-

stamping

-

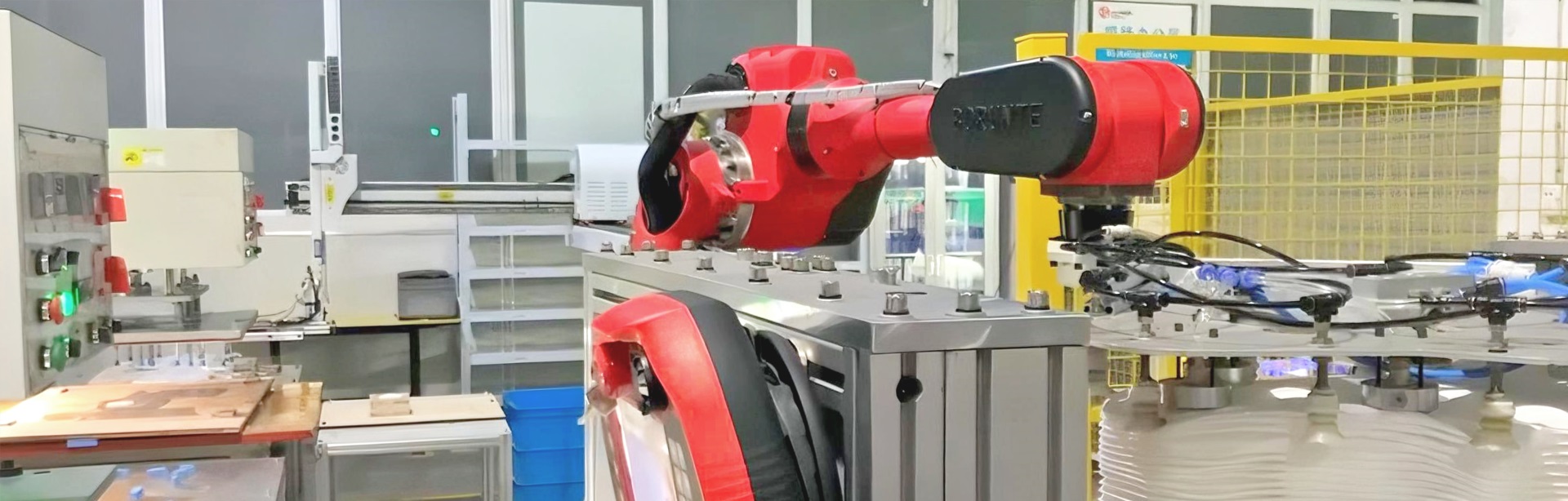

Txhaj tshuaj molding

-

Polish

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj