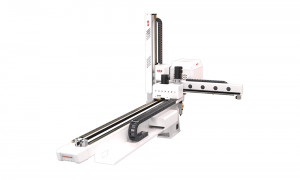

BRTNN11WSS3P/F series siv rau txhua hom kab rov tav txhaj tshuab ntau yam ntawm 250T-480T rau cov khoom nqa tawm. Lub caj npab ntsug yog hom telescopic nrog cov khoom siv caj npab. Peb-axis AC servo tsav txuag lub sijhawm ntau dua li cov qauv zoo sib xws, qhov tseeb qhov chaw, thiab lub voj voog luv luv. Tom qab kev txhim kho cov neeg hlau no, cov khoom tsim tau yuav nce 10-30% yuav txo qis tus nqi ntawm cov khoom, ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm, txo cov neeg ua haujlwm thiab tswj cov khoom kom raug kom txo cov khoom pov tseg. Peb-axis tsav tsheb thiab cov tswj kev sib xyaw ua ke: tsawg dua cov kab teeb liab, kev sib txuas lus ntev, kev nthuav dav zoo, muaj peev xwm tiv thaiv kev cuam tshuam, siab qhov tseeb ntawm qhov rov ua dua, tuaj yeem tswj tau ntau lub axes, kho cov cuab yeej yooj yim, thiab tus nqi qis qis.

Qhov tseeb qhov chaw

Ceev ceev

Lub neej ua haujlwm ntev

Tsawg Failure Rate

Txo kev ua haujlwm

Kev sib txuas lus

| Fais fab mov (kVA) | Pom zoo IMM (ton) | Traverse Tsav | Model of EOAT |

| 2.84 ib | 250T-480 T | AC Servo lub cev muaj zog | ob suctions ob fixtures |

| Txoj kab uas hla (mm) | Kab rov tav Stroke (mm) | Vertical Stroke (mm) | Max loading (kg) |

| 1700 | 3.2 | 1100 | 10 |

| Lub Sijhawm Qhuav Qhuav (sec) | Lub Sij Hawm Qhuav (sec) | Kev siv cua (NI / voj voog) | Qhov hnyav (kg) |

| 1.63 ib | 6.15 | 3.2 | 305 |

Qauv sawv cev: W: Telescopic hom. S: Khoom siv tes ua. S3: Peb-axis tsav los ntawm AC Servo Tsav (Traverse-axis, Vertical-axis + Crosswise-axis)

Lub sijhawm voj voog uas tau hais los saum toj no yog cov txiaj ntsig ntawm peb lub tuam txhab cov qauv ntsuas sab hauv. Nyob rau hauv cov txheej txheem kev thov ntawm lub tshuab, lawv yuav txawv raws li kev ua haujlwm tiag tiag.

| A | B | C | D | E | F | G |

| 1495 ib | 2727 ib | 1100 | 513 | 1700 | / | 182.5 ib |

| H | I | J | K | L | M | N |

| / | / | 1001 | / | 209 | 222 | 700 |

Tsis muaj kev ceeb toom ntxiv yog tias qhov kev qhia tshwj xeeb thiab cov tsos raug hloov vim yog kev txhim kho thiab lwm yam laj thawj. Ua tsaug rau koj nkag siab.

Cov txiaj ntsig tseem ceeb ntawm kev siv peb axis manipulator:

1. Txuag cov neeg ua haujlwm, sijhawm, thiab nyiaj txiag

2. Kev tswj kom yooj yim los txhawb kev tsim khoom

3. Ua kom tau nyiaj ntau ntxiv

4. Txhim kho txoj haujlwm ruaj ntseg

5. Txhim kho kev ua haujlwm thiab cov khoom zoo

6. Yooj yim rau kev ua haujlwm thiab kev tsim khoom zoo

1.Thaum lub sijhawm ua haujlwm, peb axis txhaj tshuaj molding manipulator tuaj yeem ua haujlwm tsis siv neeg. Nws tuaj yeem txo qhov qaug zog ntawm phau ntawv thiab txhim kho qhov tseeb thaum piv rau cov txheej txheem phau ntawv.

2.Qhov kev siv nyiaj ib zaug tuaj yeem txiav cov nqi. Nyob rau tib lub sijhawm, nws tuaj yeem ua kom zoo tshaj plaws hauv kev teb rau kev hloov pauv hauv kev lag luam, hloov kho sai sai rau kev ua lag luam, thiab pab kom cov tuam txhab hloov kho sai rau kev lag luam.

3.Installing peb-axis neeg hlau caj npab tuaj yeem ua kom muaj peev xwm ntau lawm (20% -30%), txo cov khoom lag luam tsis ua haujlwm, tswj cov neeg siv kev nyab xeeb, txo cov neeg ua haujlwm, tswj cov ntim khoom kom zoo, thiab tshem tawm cov khoom pov tseg.

1.Nws tuaj yeem siv ua ke nrog cov tshuab txiav dej tsis siv neeg thiab hauv cov pwm ntxig tshuab rau tsis siv neeg hauv pwm inserts.

2.Nws kuj tseem siv tau ua ke nrog cov khoom siv tsis siv neeg thauj khoom thiab tshem tawm cov khoom siv hauv cov khoom siv punch rau kev thauj khoom tsis siv neeg thiab tshem tawm.

3. Nyob rau hauv cov ntsiab lus, peb axis manipulator yog siv rau kev tshem tawm cov pwm txhaj tshuaj, xws li cov khoom siv hauv tsev, tsheb accessories, maus taus accessories, LED accessories (flashlights), computer accessories, kev sib txuas lus (xov tooj, ntsiav tshuaj) accessories, thiab sib txawv. cov twj paj nruag thiab ntsuas, hluav taws xob (e-luam yeeb), iav tsim khoom (cov iav), kev lag luam saib (saib casings), thiab lwm yam.

-

Txhaj Molding

Cov khoom qeb

BORUNTE thiab BORUNTE integrators

Hauv BORUNTE ecosystem, BORUNTE yog lub luag haujlwm rau R & D, tsim khoom, thiab muag khoom ntawm cov neeg hlau thiab cov neeg siv khoom. BORUNTE integrators siv lawv cov kev lag luam lossis kev ua haujlwm zoo los muab cov ntawv thov dav hlau tsim, kev sib koom ua ke, thiab kev pabcuam tomqab muag rau BORUNTE cov khoom lawv muag. BORUNTE thiab BORUNTE cov koom ua ke ua tiav lawv lub luag haujlwm thiab muaj kev ywj pheej ntawm ib leeg, ua haujlwm ua ke los txhawb lub neej yav tom ntej ntawm BORUNTE.

-

-

-

Sab saum toj