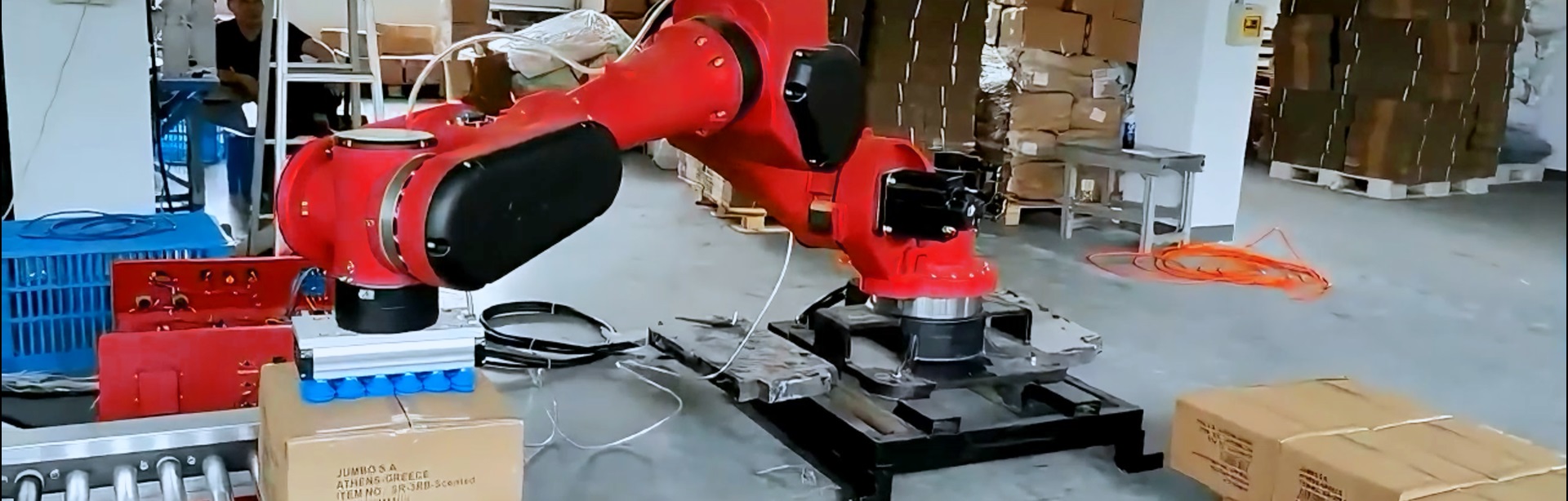

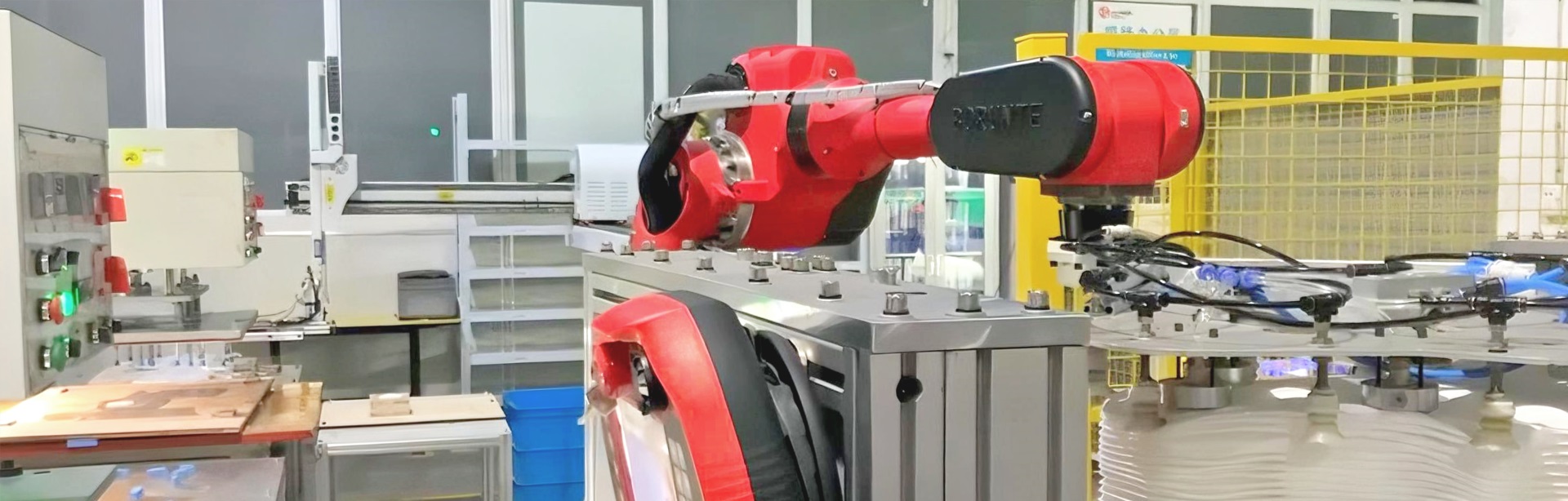

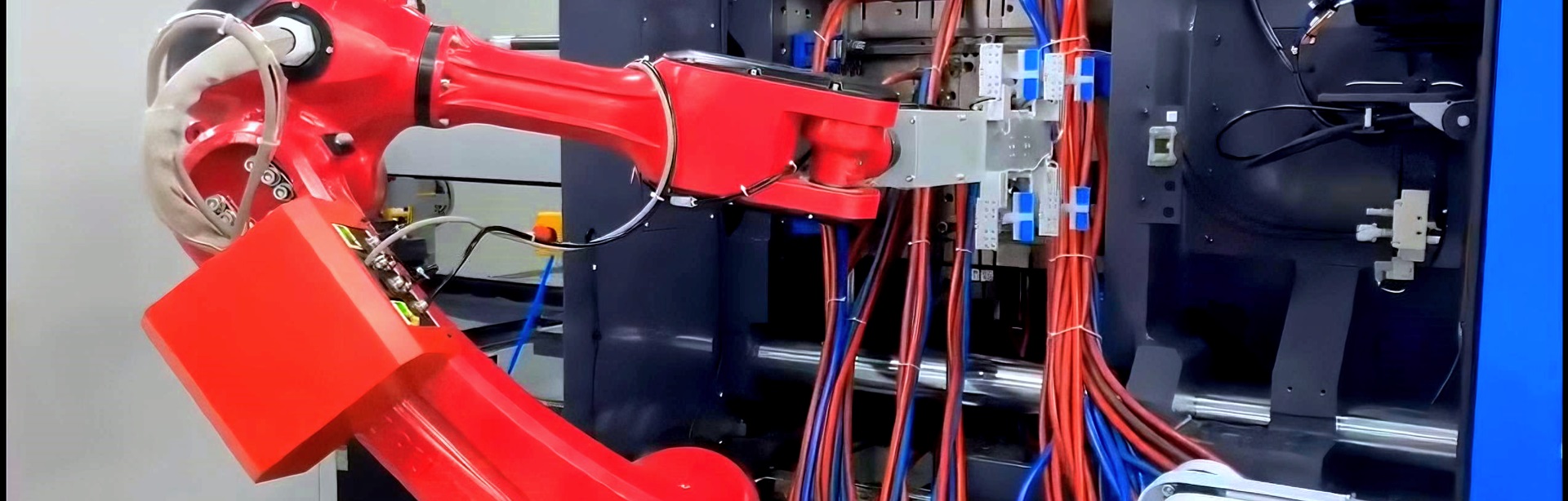

BRTIRUS2520B type robot is a six-axis robot that developed by BORUNTE for some monotonous, frequent and repetitive long-term operations or operations in dangerous and harsh environments. The maximum arm length is 2570mm. The maximum load is 200kg. It's flexible with multiple degrees of freedom. Suitable for loading and unloading, handling, stacking etc. The protection grade reaches IP40. The repeat positioning accuracy is ±0.2mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

63°/s |

|

|

J2 |

-85°/+35° |

52°/s |

||

|

J3 |

-80°/+105° |

52°/s |

||

|

Wrist |

J4 |

±180° |

94°/s |

|

|

J5 |

±95° |

101°/s |

||

|

J6 |

±360° |

133°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2570 |

200 |

±0.2 |

9.58 |

1106 |

Four significant features of BTIRUS2520B

1. The BRTIRUS2520B is a 6-axis industrial robot with a high-performance motion control platform that offers great performance, quick processing speed, and industry-leading reliability.

2. This robot is appropriate for a variety of sectors, including automotive, electronics, consumer products, and machinery, and its excellent manipulation capability meets the needs of many automated production activities. It is built to withstand tough industrial environments, delivering constant and dependable performance in terms of speed and accuracy.

3. This industrial robot has a high load capacity of up to 200kg and is ideal for a variety of demanding automated operations.

4. To summarize, the BRTIRUS2520B is well-equipped to optimize production processes and is an excellent choice for heavy-duty industrial robot applications. It may be employed in sectors such as automation, assembly, welding, and material handling because to its robust motion control platform, dependable durability, and industry-leading agility.

1. Assembly Line Optimization: This industrial robot excels in assembly line activities, handling delicate components with precision and reducing human error. It dramatically increases production speed and assures constant quality by automating repetitive activities, resulting in cost savings and enhanced customer satisfaction.

2. Material Handling and Packaging: The robot streamlines material handling and packaging procedures with its durable construction and reversible grippers. It can effectively pack things, position products in an orderly fashion, and carry big loads with ease, simplifying logistics and lowering the need for manual labor.

3. Welding and Fabrication: The autonomous general purpose industrial robot is perfect for welding and fabrication activities because it produces accurate and consistent welds. Because of its powerful vision systems and motion control, it can negotiate difficult shapes, providing improved welding quality and saving material waste.

-

transport

-

stamping

-

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top